Preparation method for metal key-press with corrugated brightness

A key and metal technology, applied in the field of metal key production, can solve the problems such as the transparent plastic film 2a and the transparent elastic layer 5a cannot be fully squeezed, the internal circuit is short-circuited, and the appearance of the metal key 10a is dull and visually dull.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

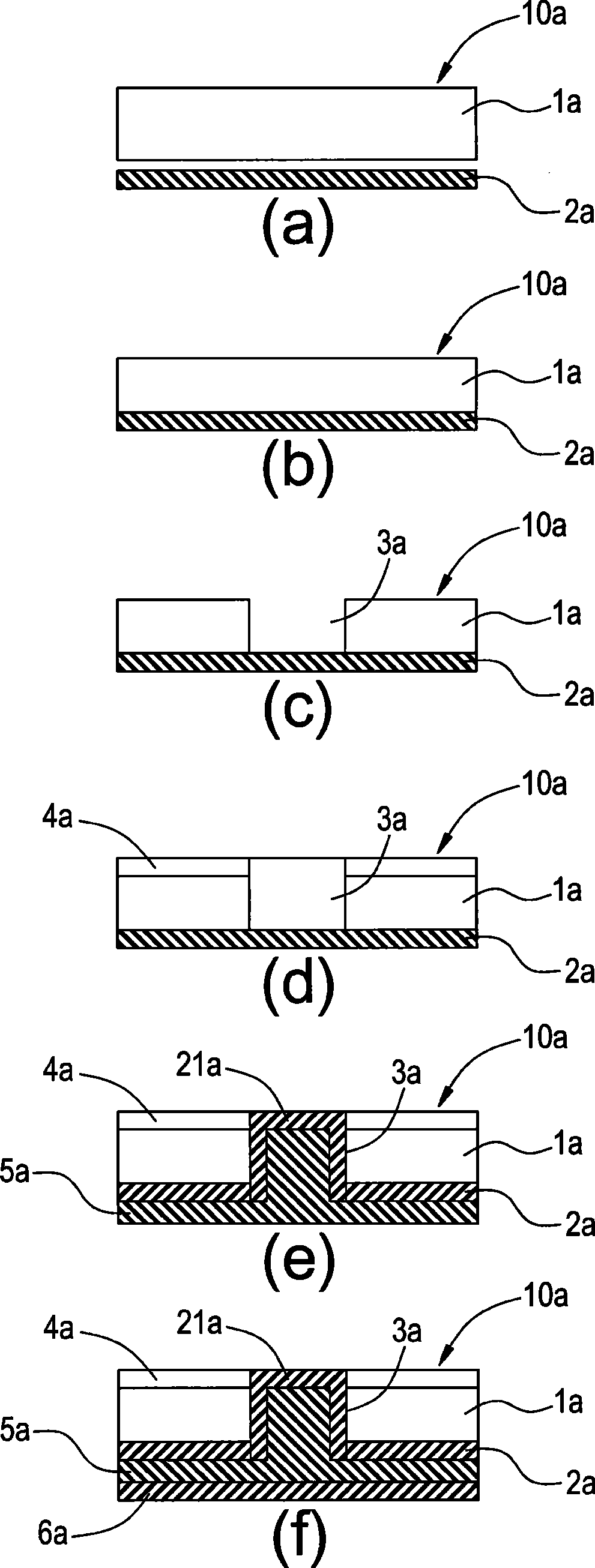

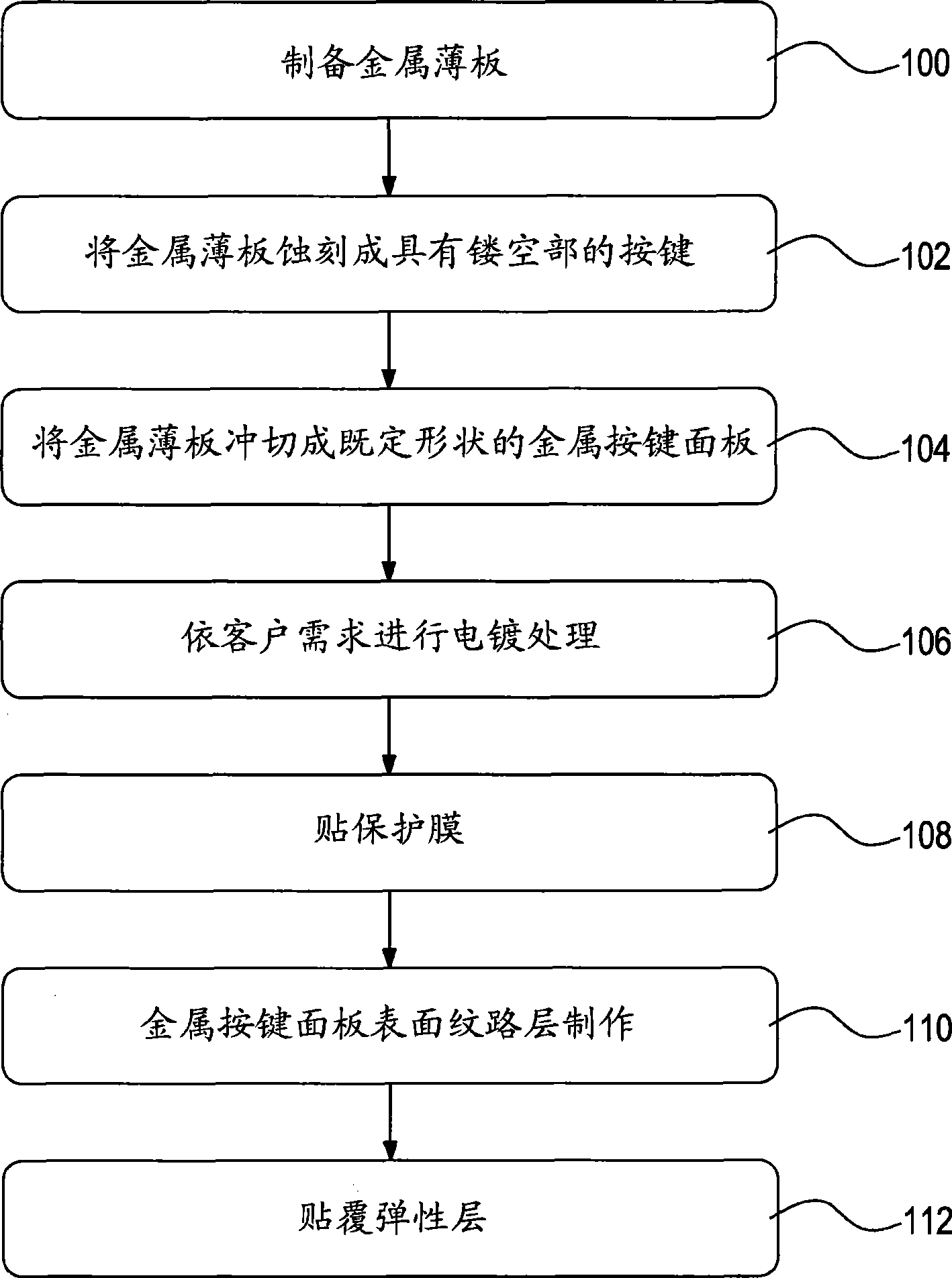

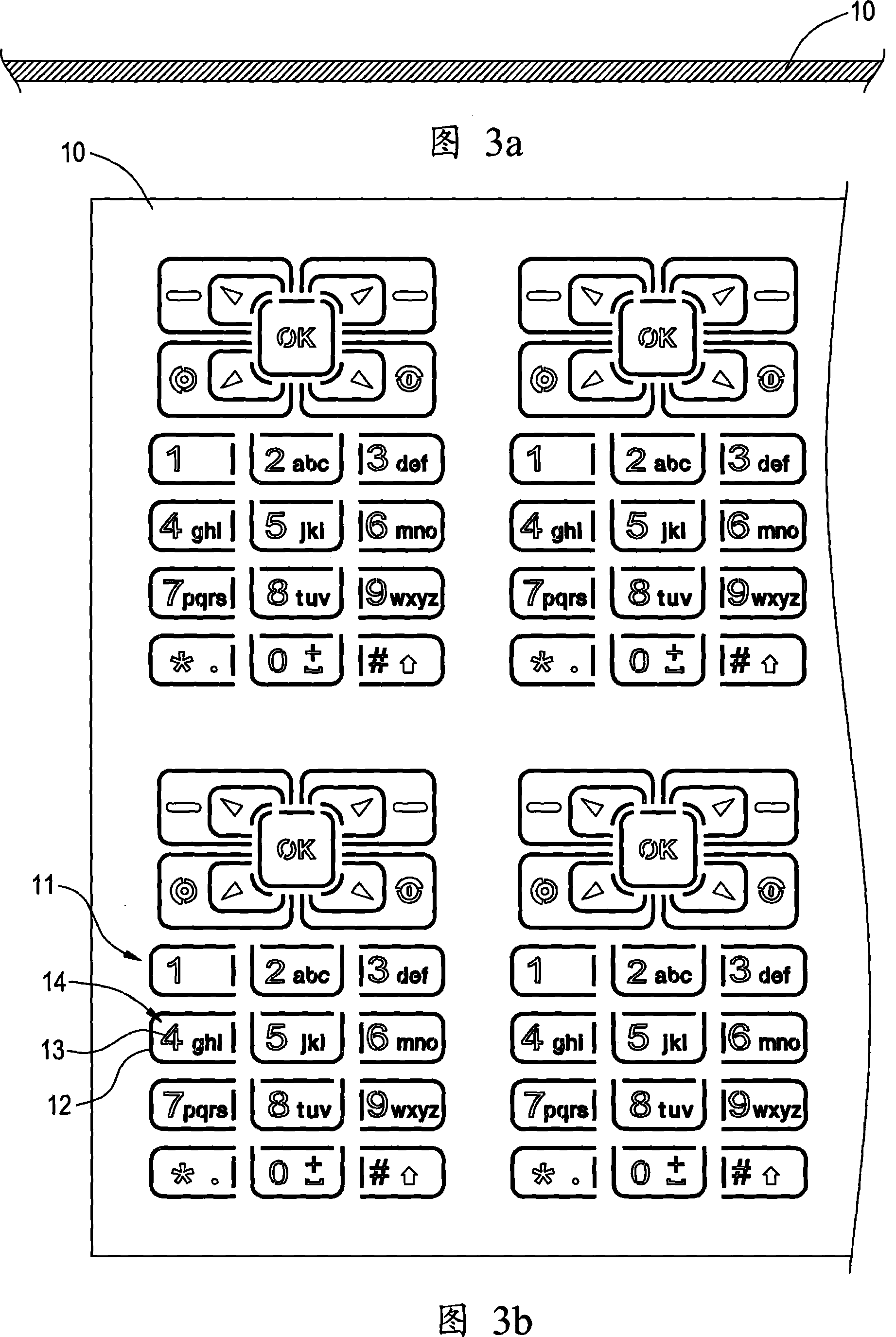

[0045] The technical content of the present invention is described in detail below in conjunction with accompanying drawing: figure 2 It is a schematic diagram of the metal button production process of the present invention. As shown in the figure: please refer to Fig. 3 for the manufacturing method of the metal button with corrugated luster of the present invention. First, as in step 100, a thin metal plate 10 is prepared, as shown in Fig. 3(a), the thin metal plate 10 is stainless steel (SUS) or aluminum-magnesium alloy materials.

[0046] In step 102 , etching is performed on the thin metal plate 10 to form a plurality of hollow parts 11 on the thin metal plate 10 . The hollow parts 11 are divided into line hollow parts 12 and pattern hollow parts 13 . The pressing area 14 of the key is defined by the line hollow part 12, and the graphic hollow part 13 is set as a graphic on the surface of the pressing area 14, which includes numbers (0-9), characters (A-Z), special symbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com