LED chip component with heat-dissipating substrate and preparation method thereof

A technology of light-emitting diodes and heat-dissipating substrates, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of destroying the heat conduction interface, affecting the heat dissipation efficiency of the component 1, and reducing the thermal resistance. Heat dissipation issues, the effect of improving light performance and working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

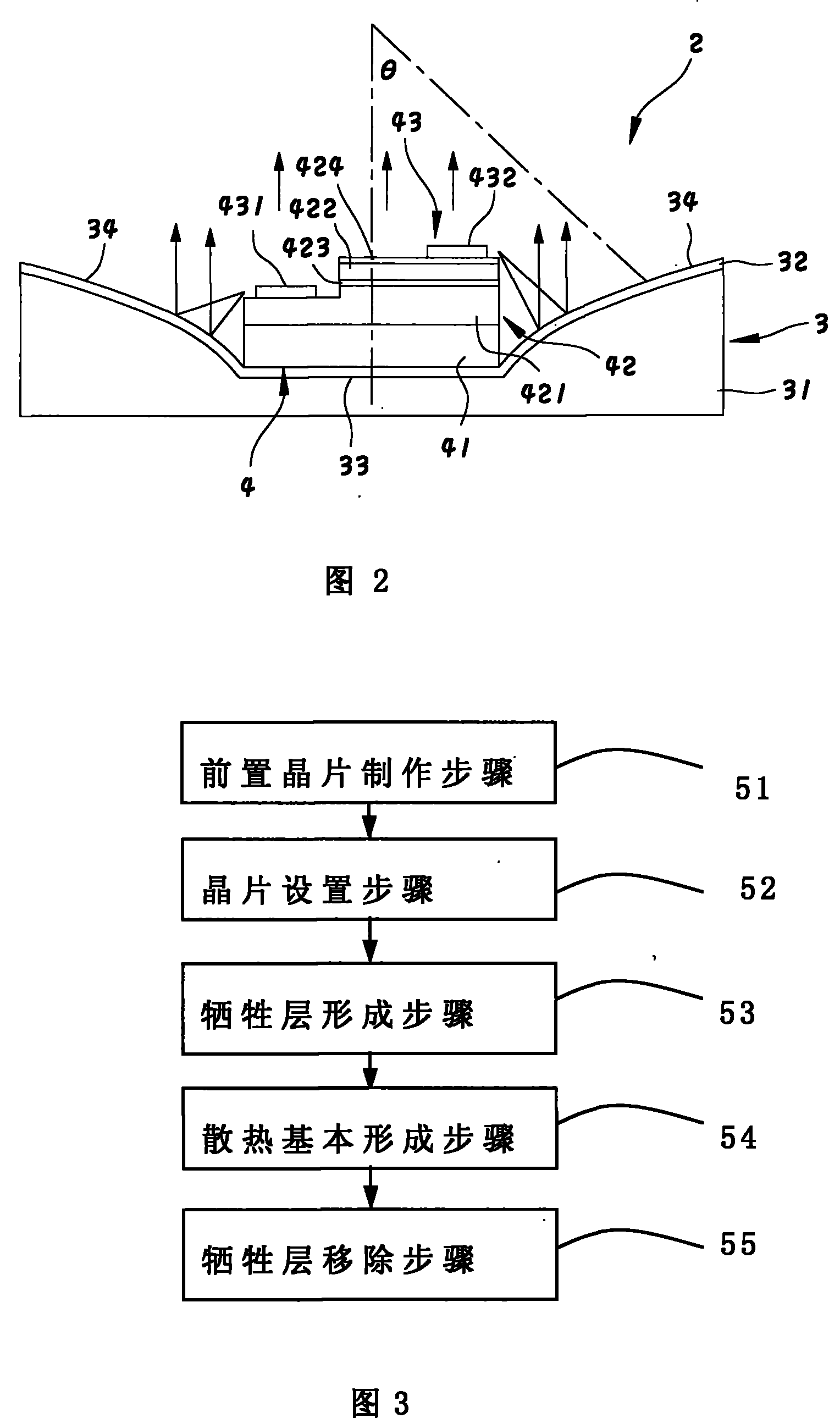

[0028] refer to figure 2 , which is a first preferred embodiment of the light-emitting diode chip assembly 2 with a heat-dissipating substrate in the present invention, including a heat-dissipating substrate 3, and at least one light-emitting diode chip 4 disposed on the heat-dissipating substrate 3, in this example, Only one light emitting diode chip 4 is provided, and the light emitting diode chip 4 is a general horizontal conducting light emitting diode chip.

[0029] The heat dissipation substrate 3 is made of a material with high thermal conductivity, and can be formed by using a single material such as copper, gold, silver, nickel, tin, titanium, platinum, palladium, tungsten, molybdenum, or a combination of these materials. Substrate 31, and a mirror 32 formed on the substrate 31 to reflect light with a material having a high reflectance at the same time; in terms of its structure, it has a central portion 33, and a reflective portion 34 surrounding the central portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com