Method and device for gas-solid reaction

A gas-solid reaction and reaction technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high labor intensity, solid material take away, and difficulty in meeting the needs of compressors, so as to increase production and improve reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

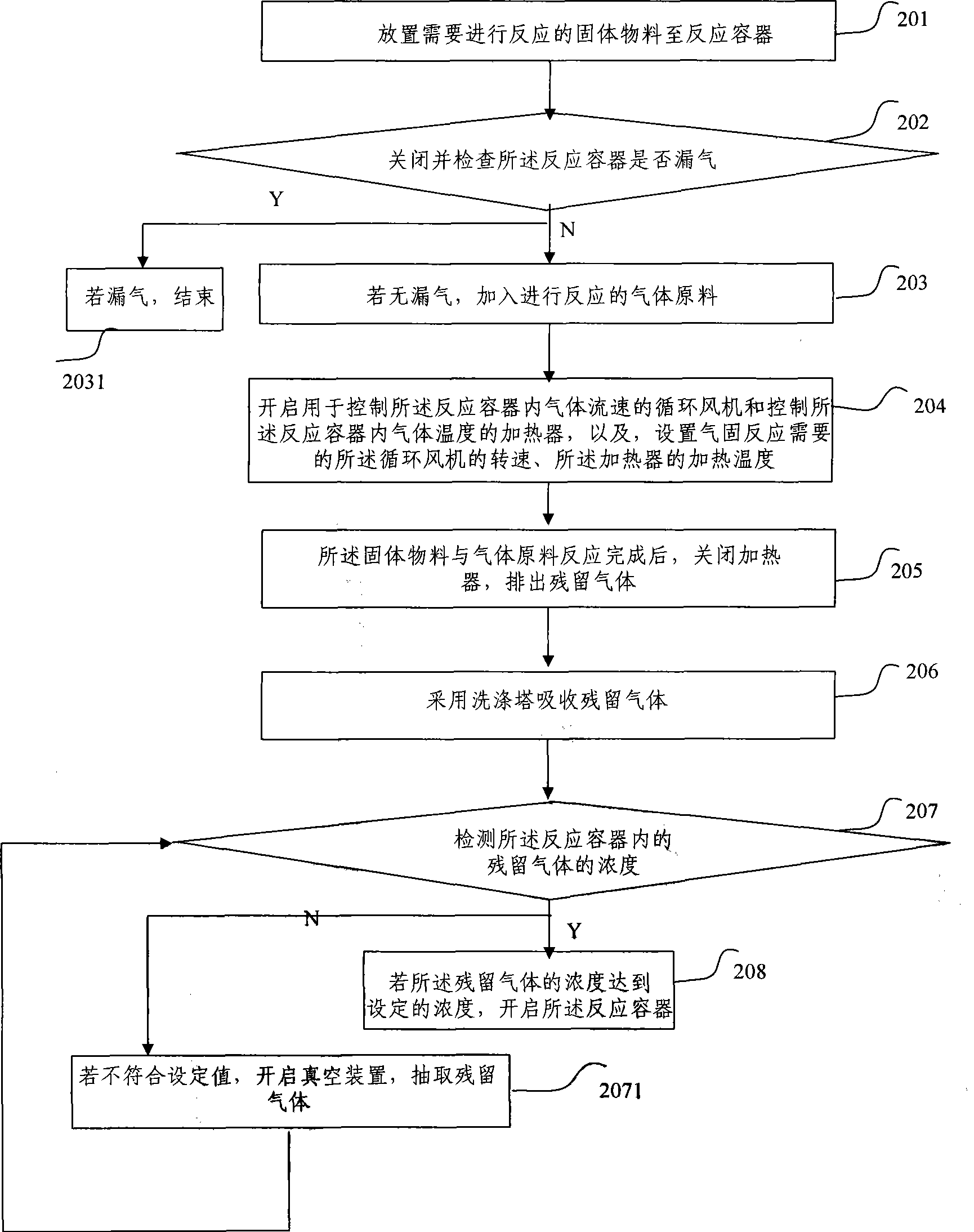

[0063] refer to figure 2 The schematic flow sheet of the gas-solid reaction method of the present invention shown, the step of the method for its described gas-solid reaction mainly comprises:

[0064] Step 201: placing the solid material to be reacted into the reaction container;

[0065] In a preferred embodiment of the present invention, the sub-steps of step 201 may include,

[0066] Sub-step S1: Take out the shelves and material trays in the reaction container;

[0067] Sub-step S2: loading the material tray containing the solid material into the shelf;

[0068] Sub-step S3: placing the shelf containing the solid material into the reaction container.

[0069] Step 202: Close and check whether the reaction container is leaking, if there is no leak, execute step 203, add the gas raw material for reaction; if check the reaction container is leaking, execute step 2031, end the operation, or restart Select reaction vessel, repeat all above-mentioned steps of present embod...

Embodiment 2

[0096] The gas-solid reaction device of the present invention will be introduced in detail below.

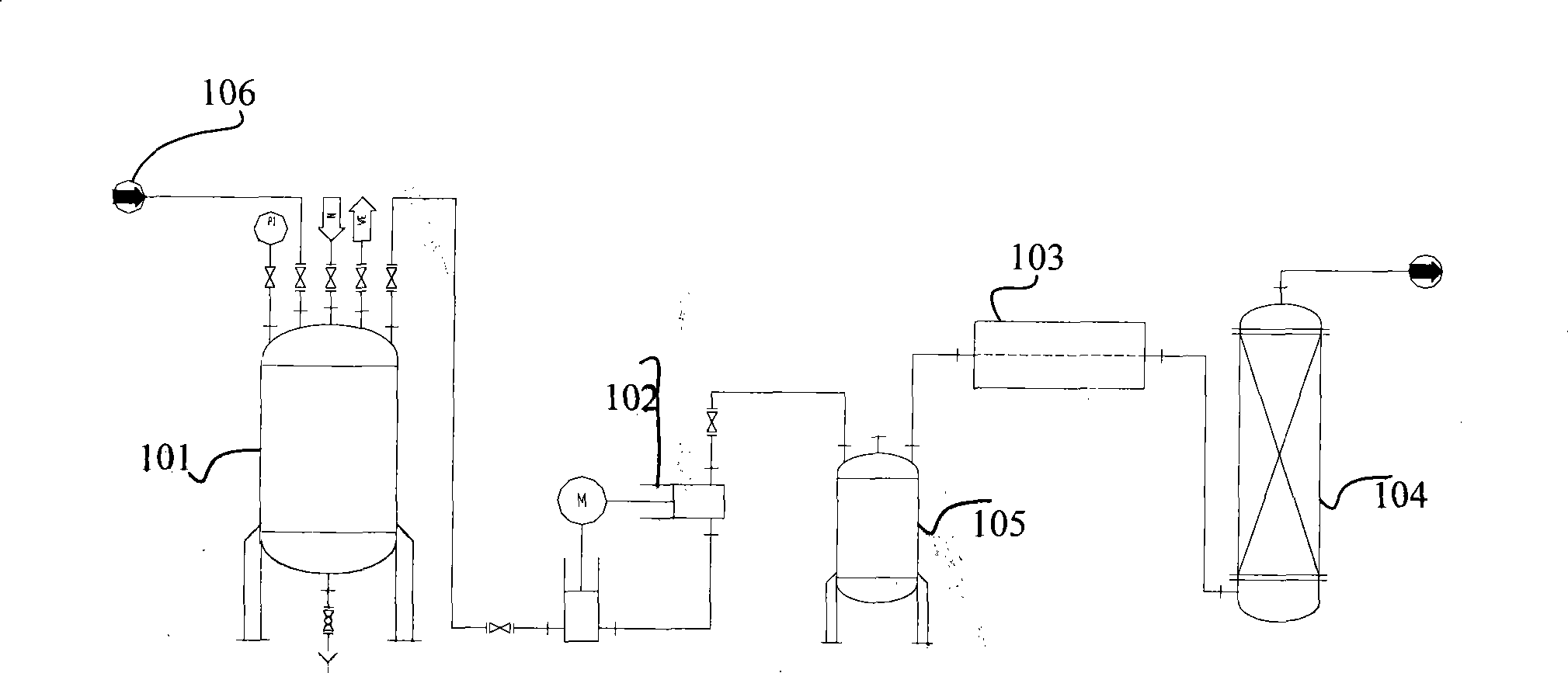

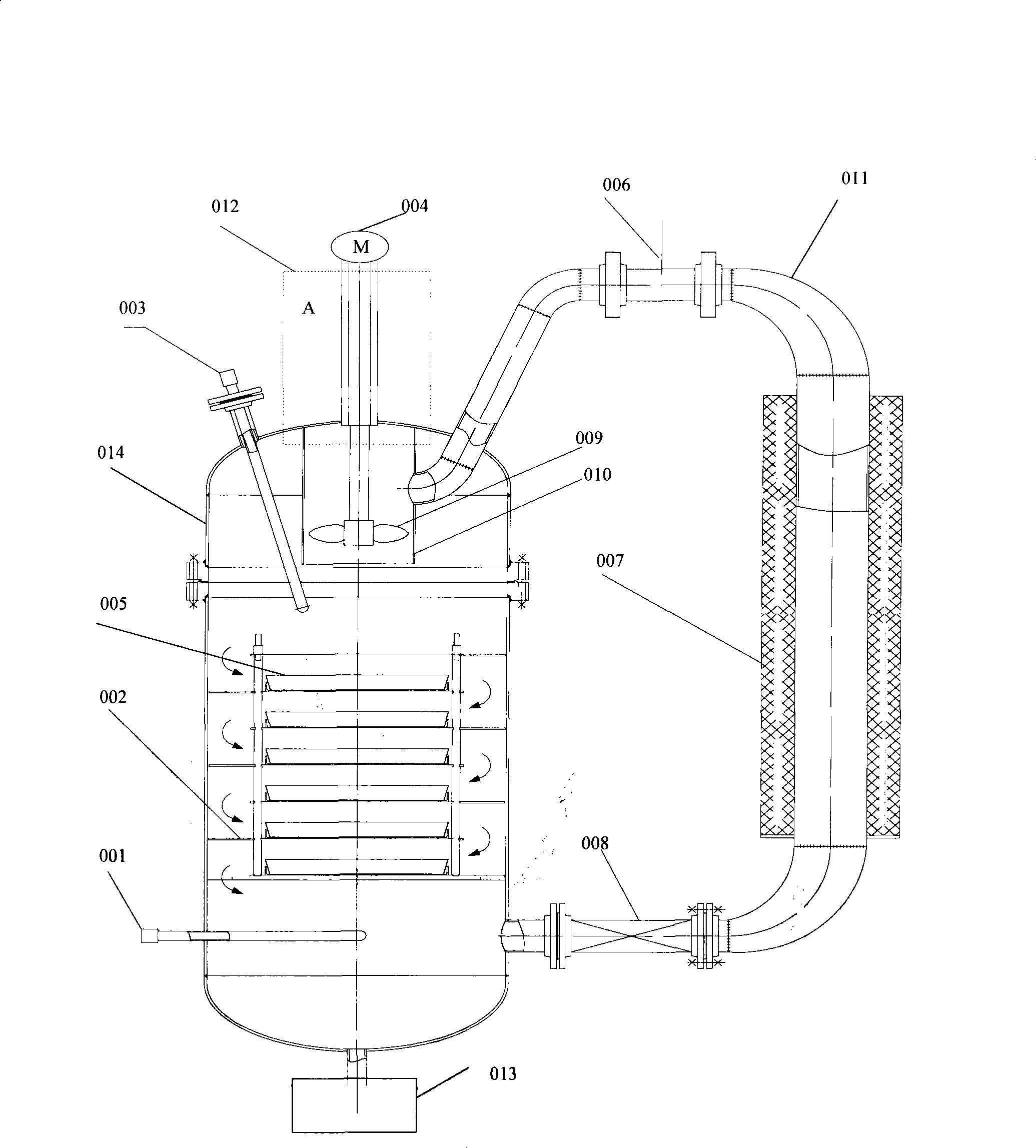

[0097] refer to image 3 , Figure 4 with Figure 5 , showing a schematic structural view of a gas-solid reaction vessel of the present invention, image 3 The enlarged structural schematic diagram of the A part of the middle reaction vessel, and the structural schematic diagram of the gas-solid reaction overall device, image 3 with Figure 5 The middle arrow indicates the flow direction of the gaseous material in the reaction vessel, from image 3 It can be seen that the airflow is deflected in the direction of the front. The solid material is placed in the material tray 005 on the shelf 002, and the airflow flows through the surface of the material tray 005.

[0098] The gas-solid reaction device of this embodiment mainly includes a reaction vessel 014, a circulating fan, a heating device 011, and a detection device;

[0099] When the gas raw material is a toxic or corro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com