Fuel truck nozzle

A fueling gun and fuel oil technology, which is applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of reducing the average flow rate of liquid in the pipeline and prolonging the time, so as to improve performance stability and work reliability. The effect of reducing the hammer pressure and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

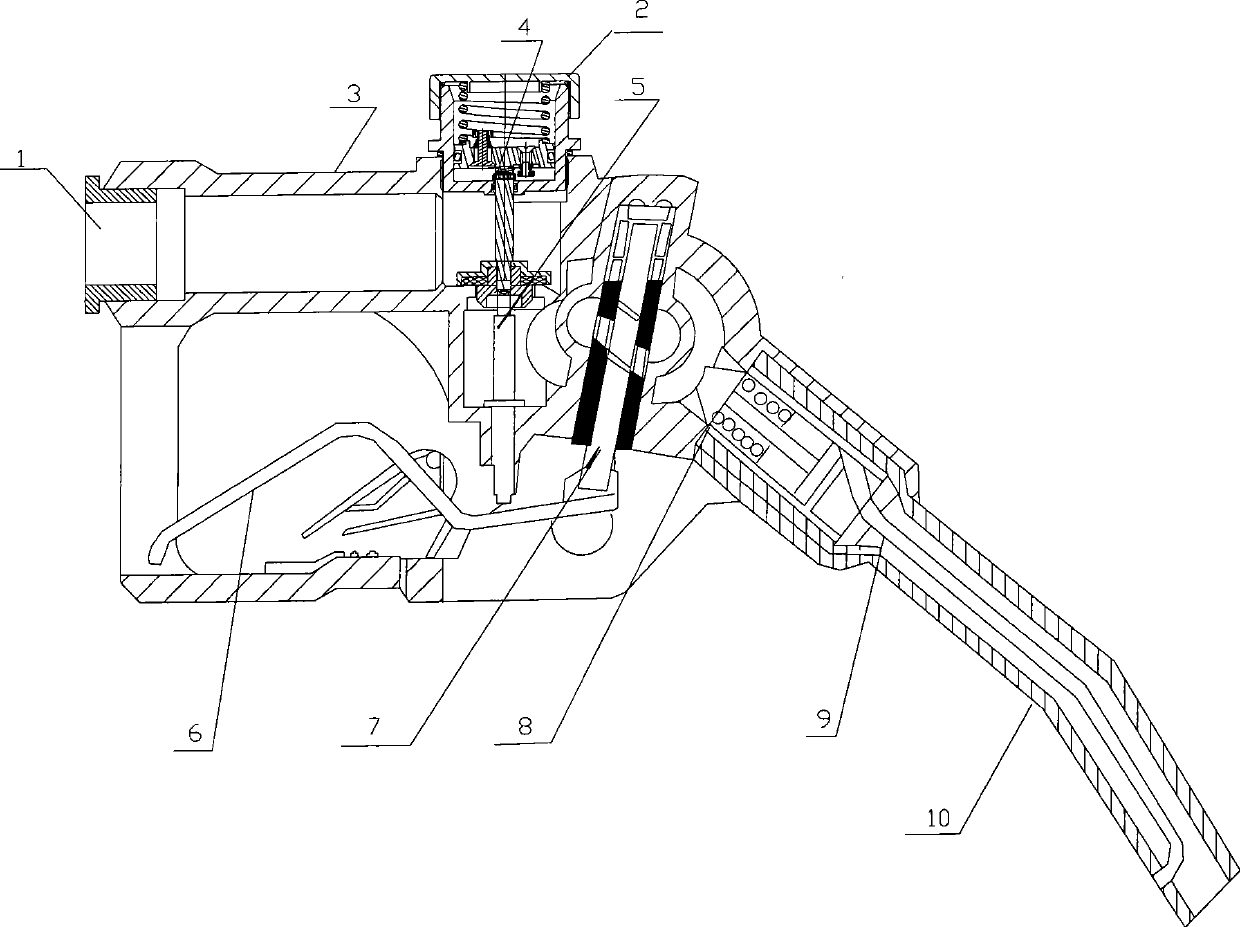

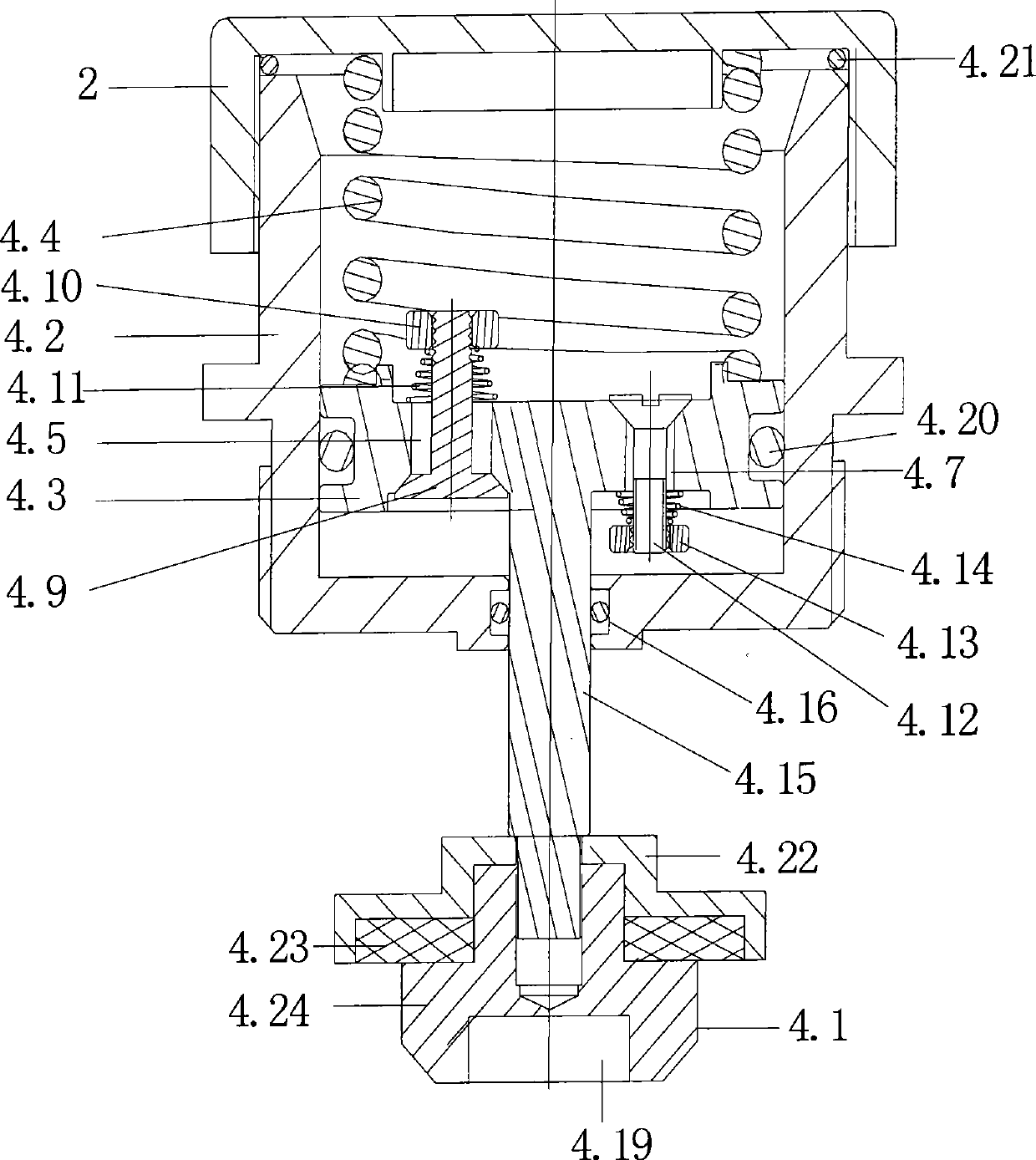

[0034] The structure of the fuel filler gun of the present invention is as figure 1 As shown, it consists of oil inlet 1, gun body 3, gun body cover 2, control valve 4, ejector rod 5, control handle 6, self-control lever 7, vacuum valve 8, vent pipe 9, and oil outlet pipe 10. The structure of the control valve 4 is as follows figure 2 As shown, it is composed of main valve 4.1, piston cylinder 4.2, piston 4.3 and the spring 4.4 whose two ends respectively resist the lower end surface of the gun body cover 2 and the upper end surface of the piston 4.3. The gun body cover 2 and the piston cylinder 4.2 are threadedly connected. An O-ring 4.21 is provided between the body cover 2 and the piston cylinder 4.2. The lower end surface of the gun body cover 2 is provided with a boss on which one end of the spring 4.4 is fixed, which is conducive to the fixed installation of the spring 4.4. The circumference of the piston 4.3 is provided with an annular groove, and the piston 4.3 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com