Method for treating unsaturated polyester resins wastewater

A polyester resin, unsaturated technology, applied in the field of treating unsaturated polyester resin production wastewater to make it effective, can solve the problems of secondary pollution, long cycle, high cost of chemical treatment, etc., to improve quality and improve water reduction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

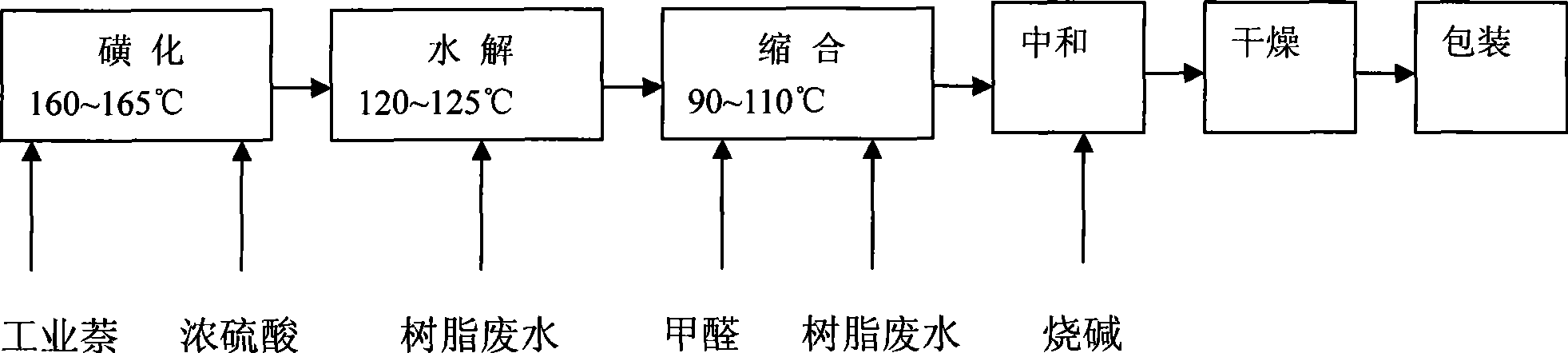

[0007] At present, the industrial production process of naphthalene-based water reducer is roughly as follows:

[0008] 1. Mix a certain amount of industrial naphthalene and concentrated sulfuric acid in proportion, and carry out sulfonation reaction at 160-165°C;

[0009] 2. Add waste water containing low molecular weight alcohol and acid produced in the production of unsaturated polyester resin to the reaction product, carry out hydrolysis reaction at 120-125°C, add 250-300Kg of the waste water for every 10 tons of water reducing agent produced ;

[0010] 3. Add formaldehyde to the reaction product of the previous step and the waste water containing low molecular weight alcohol and acid produced in the production of unsaturated polyester resin, and carry out condensation reaction at 90-110°C. For every 10 tons of water reducing agent produced, add the Wastewater 150-200Kg;

[0011] 4. Add lye to the reaction product of the previous step to carry out neutralization reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com