Method for making cake-pounding adhibit cake

A production method and sticky cake technology, which are applied in the field of pounding and sticky cake production, can solve the problems of reduced taste, poor quality of sticky cakes, irregular texture characteristics of sticky cakes, etc., and achieve the effects of cost saving, environmental pollution reduction and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

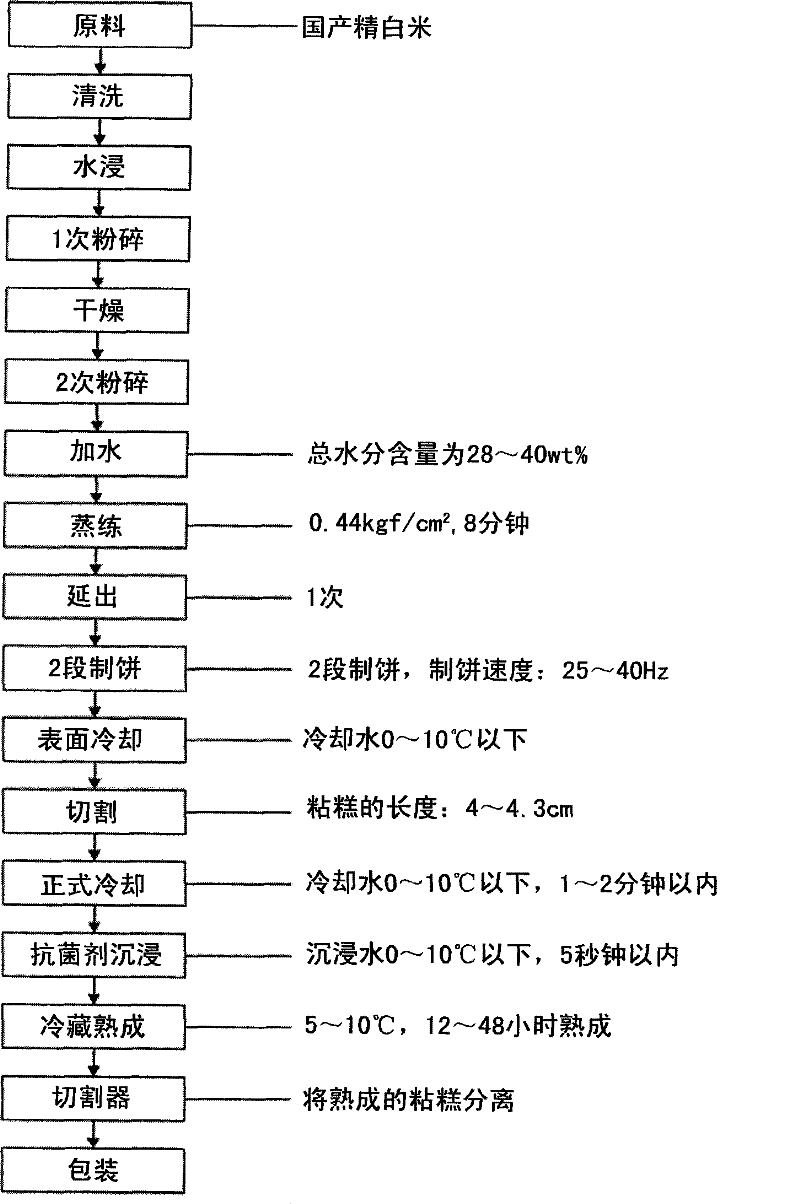

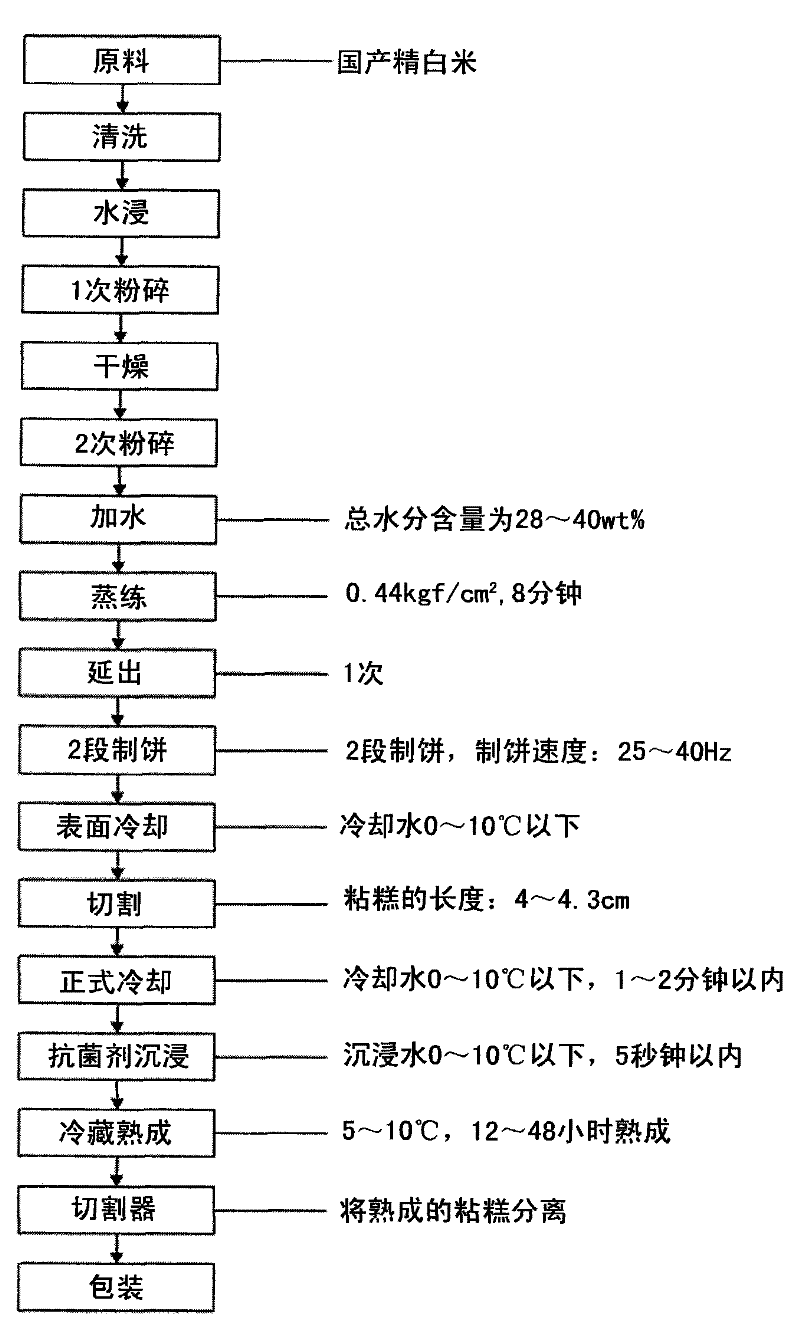

Method used

Image

Examples

Embodiment 1

[0030] Example 1 (Making of mashed cake and sticky cake)

[0031] After immersing the rice for 2 hours, it was pulverized by a roller mill 1 and then put into a fluidized bed to be dried so that the moisture content of the rice noodles reached 10%, and then it was pulverized by a jet mill 2 The second pulverization makes the average particle size of the rice noodles reach 150 meshes to make rice noodles.

[0032] Water is added to the prepared rice noodles to make the total water content reach 37wt%, and then steamed for 8 minutes with a steaming machine to make dough. Put the made dough into the spreader, spread it out and mix it once, and then continuously perform two-stage cake making to make a sticky cake. When performing the cake making process, the thickness of the sticky cake is 14mm and the width is 44mm. After cooling the above sticky cake and adding a natural antibacterial agent (Grapefruit seed extract) for immersion, it is placed in a refrigerator (5°C) for 24 hours t...

experiment example 1

[0034] Experimental example 1 (Preference evaluation)

[0035] The mashed cake noodles made according to the above-mentioned Example 1 were made into mashed cake noodles using ordinary production methods, and then the mashed cake noodles were divided among 50 housewives for evaluation. A questionnaire survey was conducted on resilience and other aspects. The questionnaire used a 5-point scale. The results are shown in Table 1 below.

[0036] 【Table 1】

[0037] Exterior Harmony Surface toughness Example 13.963.744.16 Commercial sticky cake 3.273.602.98

[0038] (5: very good, 4: relatively good, 3: average, 2: relatively poor, 1: very bad)

[0039] As shown in Table 1 above, the mashed cake made by the method of the present invention has better quality and higher evaluation than the sticky cake made by the existing sticky cake production method. Compared with existing manufacturing methods, the method of the present invention is more excellent in terms of appearance, harmony and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com