Improved UCT sewage disposal system and method for treating same

A sewage treatment system and sewage technology, applied in the field of sewage treatment, can solve the problems of complex system, high operating cost and high engineering cost, and achieve the effect of improving reaction efficiency, reducing operating cost, and simple structure and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

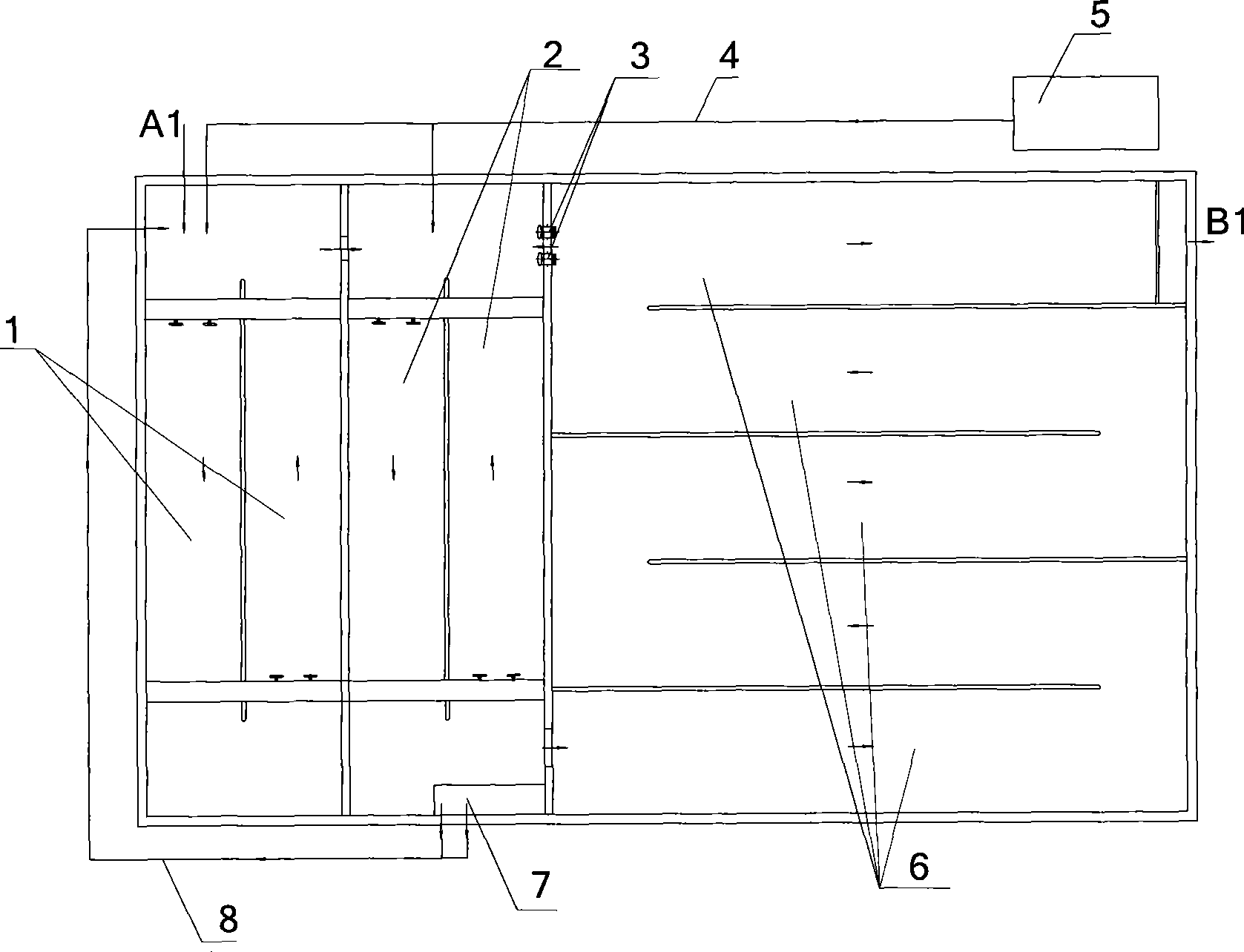

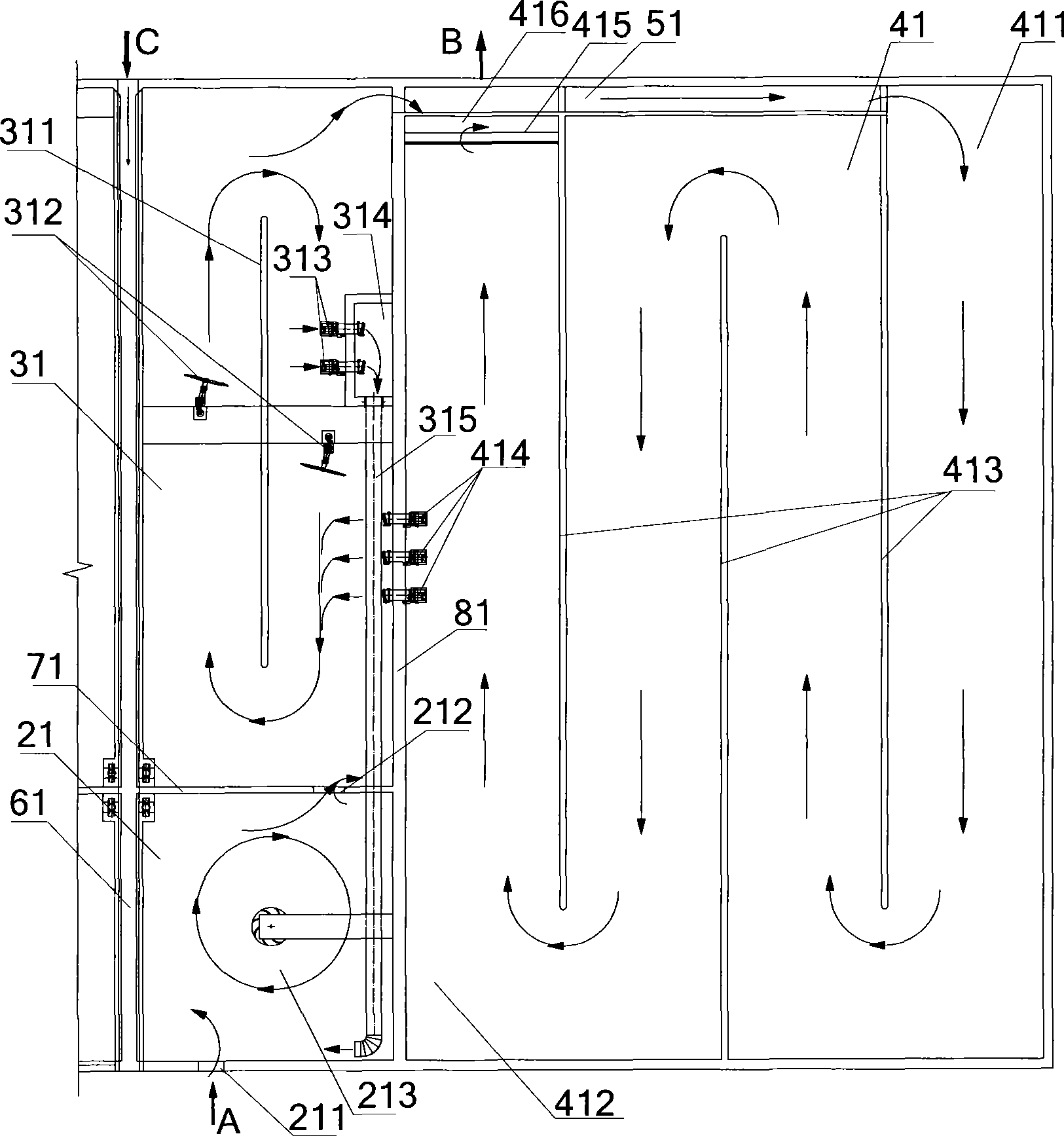

[0027] This embodiment provides an improved UCT sewage treatment system for treating urban and industrial sewage, such as figure 2As shown, the system specifically includes:

[0028] Anaerobic reaction pool 21, anoxic reaction pool 31 and aerobic reaction pool 41; Wherein, anaerobic reaction pool 21 is provided with sewage water inlet 211 and sewage water outlet 212, is provided with rotary cutting vortex vertical mixer in anaerobic reaction pool 213, the anaerobic reaction pool 21 communicates with the anoxic reaction pool 31 through the sewage outlet 212, and the end of the anoxic reaction pool 31 is connected back to the anaerobic reaction pool 21 through the mixed liquid return pipe 315, and the outlet at the end of the anoxic reaction pool 31 The water inlet is connected to the water inlet at the front end of the aerobic reaction tank 41 through the water delivery channel 51, and the side wall of the anoxic reaction tank and the side wall at the end of the aerobic reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com