Rotating roller dual cycle cooling system

A cooling system and rotating roller technology, applied in the direction of mechanical treatment of leather surface, etc., can solve the problems affecting the dynamic balance accuracy of rotating rollers, poor air-cooling cooling effect, and corrosion of the roller body, so as to ensure the dynamic balance accuracy and service life, reduce Small amount of thermal expansion and deformation, ensuring the effect of working accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

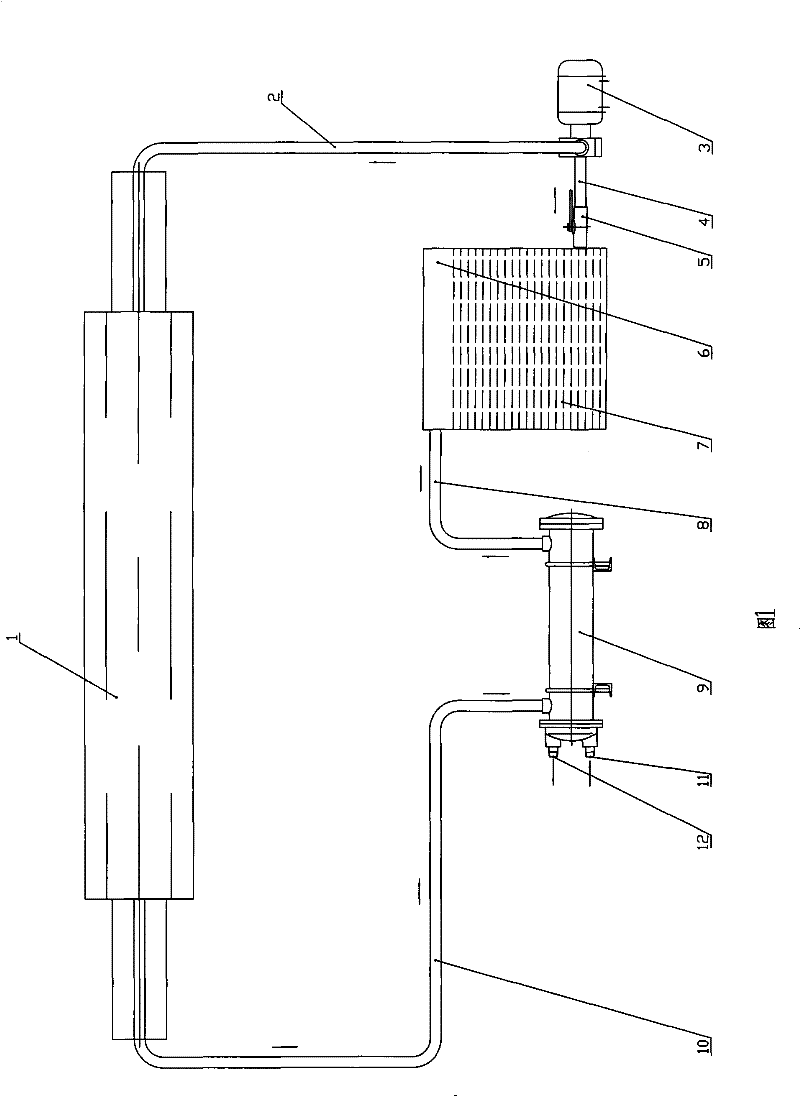

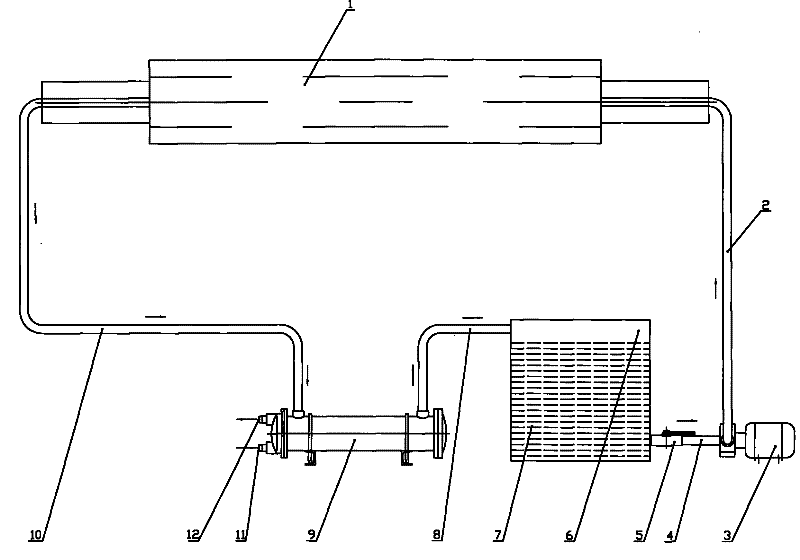

[0013] refer to figure 1 , the rotating roller double circulation cooling system, including the rotating roller 1, the inlet of the rotating roller 1 is connected to the cooling water tank 6 through the water delivery device, the outlet of the rotating roller 1 is connected to the cooling water tank 6 through the water return device, and the cooling water tank 6 is filled with emulsion 7. The water delivery device includes a drain pipe 2, a water pump 3, a water suction pipe 4, and a ball valve 5. The outlet of the water pump 3 is connected to the inlet of the rotary roller 1 through the drain pipe 2, and the suction port of the water pump 3 is connected to the cooling water tank 6 through the water suction pipe 4, the ball valve 5 connect. The water return device includes a second water return pipe 8, a cooler 9, and a first water return pipe 10. The inlet of the cooler 9 is connected to the outlet of the rotating roller 1 through the first water return pipe 10, and the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com