Alumina coating correlation technique with alpha type crystal structure

A crystal structure, alumina technology, applied in the plating, coating, metal material coating process of superimposed layers, etc., can solve problems such as peeling, cracked film, composition limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

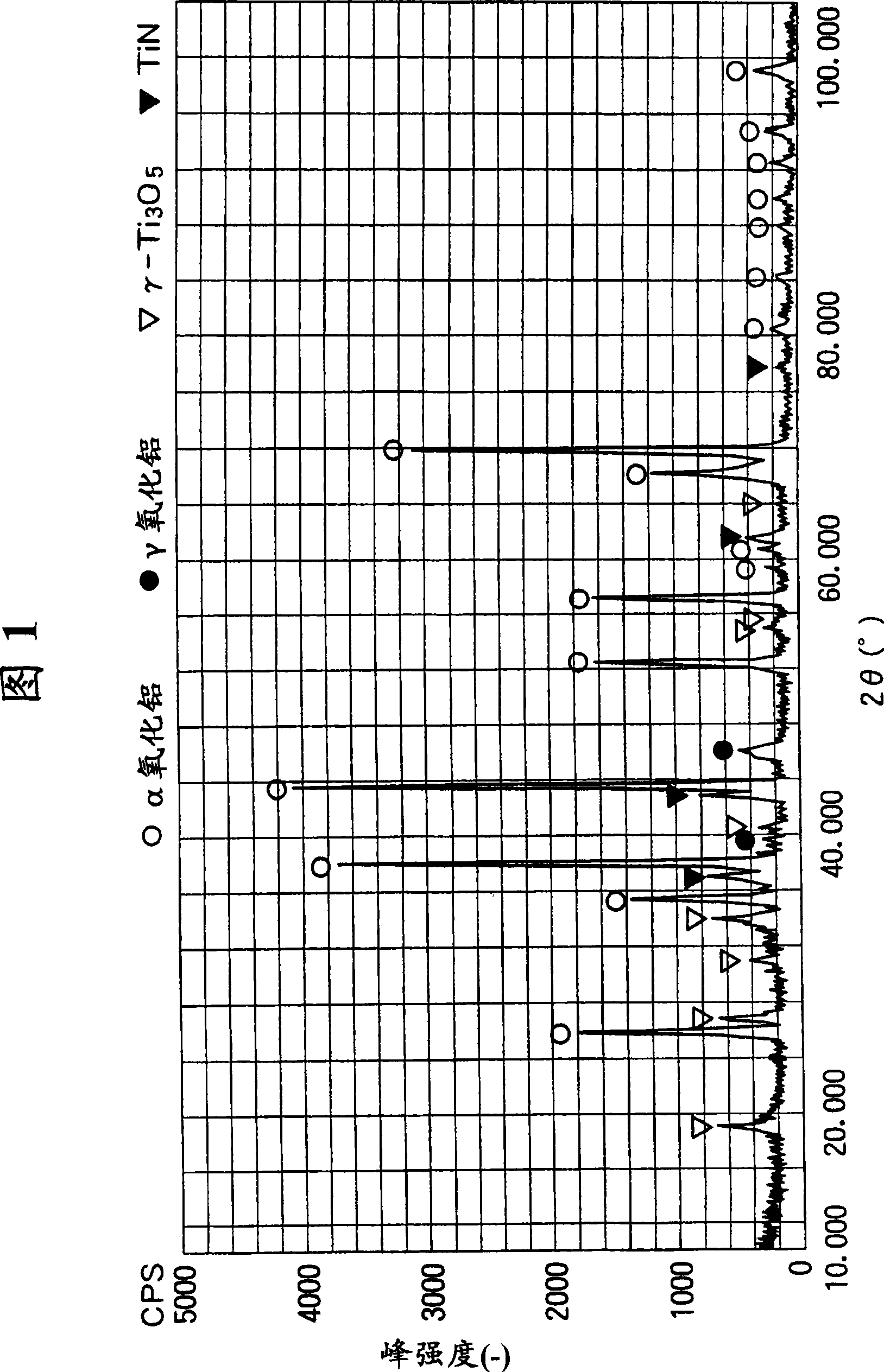

[0136] The inventors of the present invention studied a method of forming alumina mainly having an α-type crystal structure in a temperature range of about 800° C. or lower in which properties such as a hard coating and a substrate can be maintained under the above-mentioned conditions. It turns out that the following approach can be taken:

[0137] 1. As the first method, after forming a hard coating composed of Al as an essential metal component and a compound of B, C, N, O, etc., the surface of the hard coating is oxidized, and after forming an oxide-containing layer After the treatment, the method of forming a film of aluminum oxide; or 2. As a second means, using a hard oxide compound composed of a metal whose standard free energy of oxide generation is greater than aluminum and a compound such as B, C, N, O, etc. After the hard coating is formed, the surface of the hard coating is oxidized to form an oxide-containing layer, followed by reduction of the oxide on the surfa...

Embodiment 1

[0420] First, an embodiment of the above-mentioned first means (the first ① and ② method) will be described. A substrate made of cemented carbide with a size of 12.7mm×12.7mm×5mm is mirror-polished (Ra=about 0.02μm), ultrasonically cleaned and dried in an alkaline tank and a pure water tank, and then used for plating of a laminated coating cover.

[0421] In this embodiment, the formation of the hard film, the oxidation treatment of the hard film and the formation of the α-type main alumina film are all in the Figure 4 It carried out in the vacuum film-forming apparatus shown (Kobe Steel Co., Ltd. AIP-S40 composite machine).

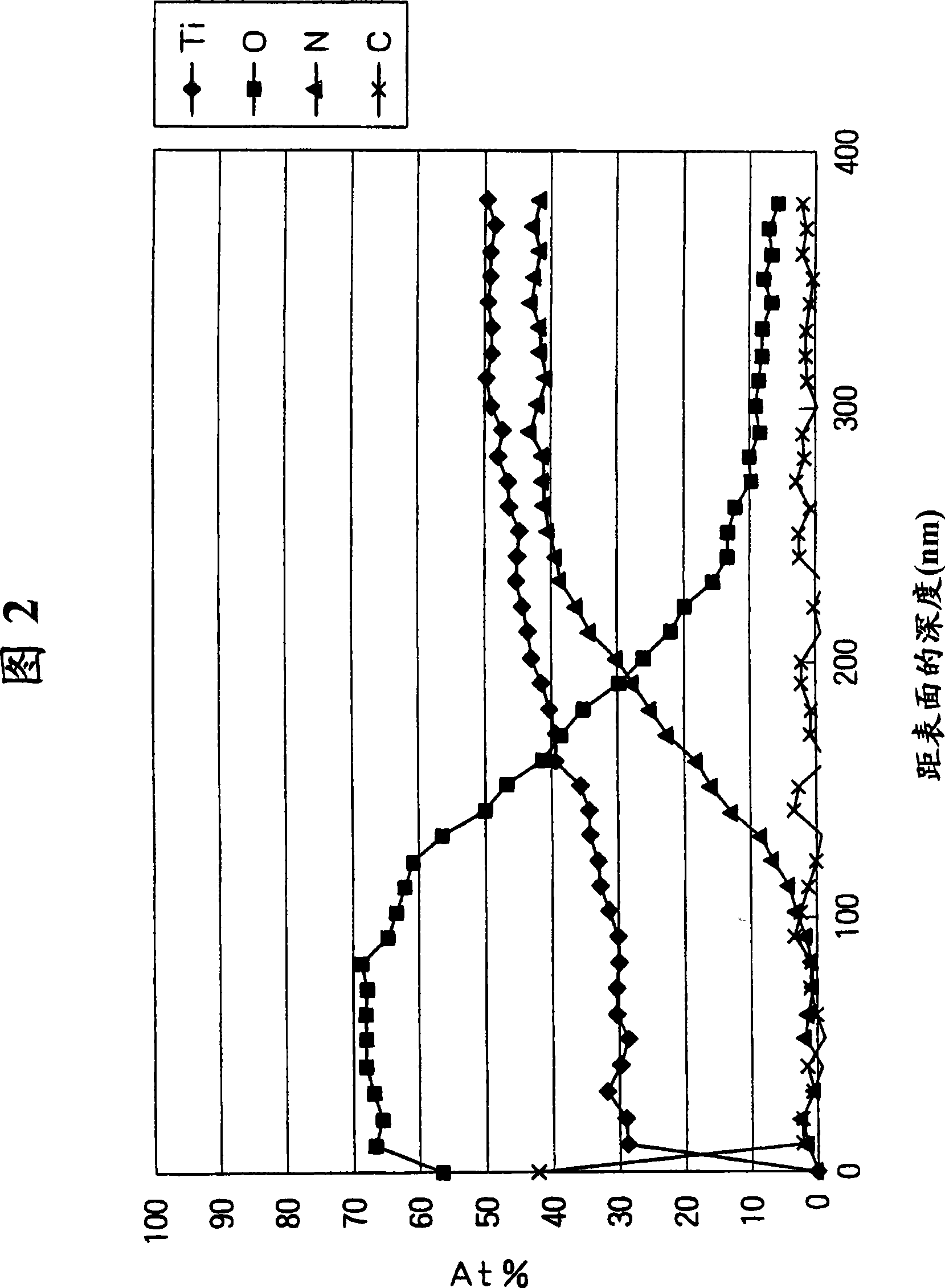

[0422] The hard coating on the substrate is formed in Figure 4 In the device 1 shown, the evaporation source 7 for AIP is used for AIP method (arc ion plating method) to form a TiAlN hard coating with a film thickness of 2 to 3 μm and an atomic ratio of Ti and Al (Ti:Al) of 0.55:0.45. A coating or a TiAlCrN hard coating having an atomic ratio of Ti, A...

Embodiment 2

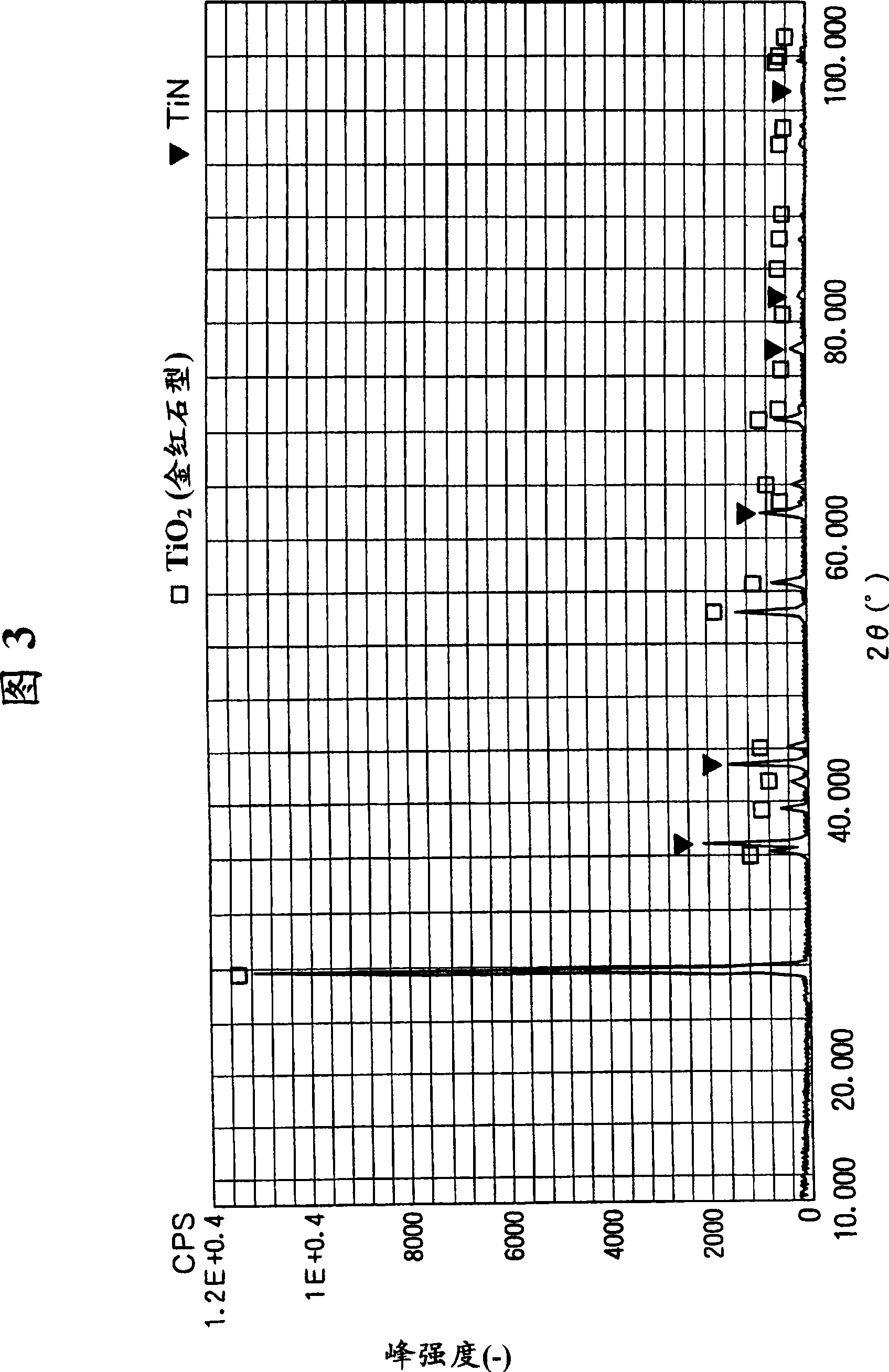

[0438] Next, an embodiment of the above-mentioned second means (first mode ③) will be described.

[0439] A substrate made of cemented carbide with a size of 12.7mm×12.7mm×5mm is mirror-polished (Ra=about 0.02μm), ultrasonically cleaned and dried in an alkaline tank and a pure water tank, and then used for plating of a laminated coating cover.

[0440] Similar to the above-mentioned embodiment 1, in this embodiment, the formation of the hard film, the oxidation treatment of the hard film and the formation of the α-type main alumina film are all in the above-mentioned Figure 4 It carried out in the vacuum film-forming apparatus shown (Kobe Steel Co., Ltd. AIP-S40 composite machine).

[0441] The formation of a hard film on the substrate, in Figure 4 In the shown apparatus 1, a TiN film or a TiCN film with a film thickness of 2 to 3 μm is formed on a substrate by the AIP method (arc ion plating method) using the evaporation source 7 for AIP. In addition, as a reference exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com