Adsorption type drier controller

An adsorption dryer and controller technology, which is applied in the direction of machines/engines, liquid variable capacity machines, mechanical equipment, etc., can solve problems such as difficult product manufacturing, weak anti-interference ability, and imperfect functions, and achieve stable control performance Reliable, accurate control, energy saving, and perfect functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

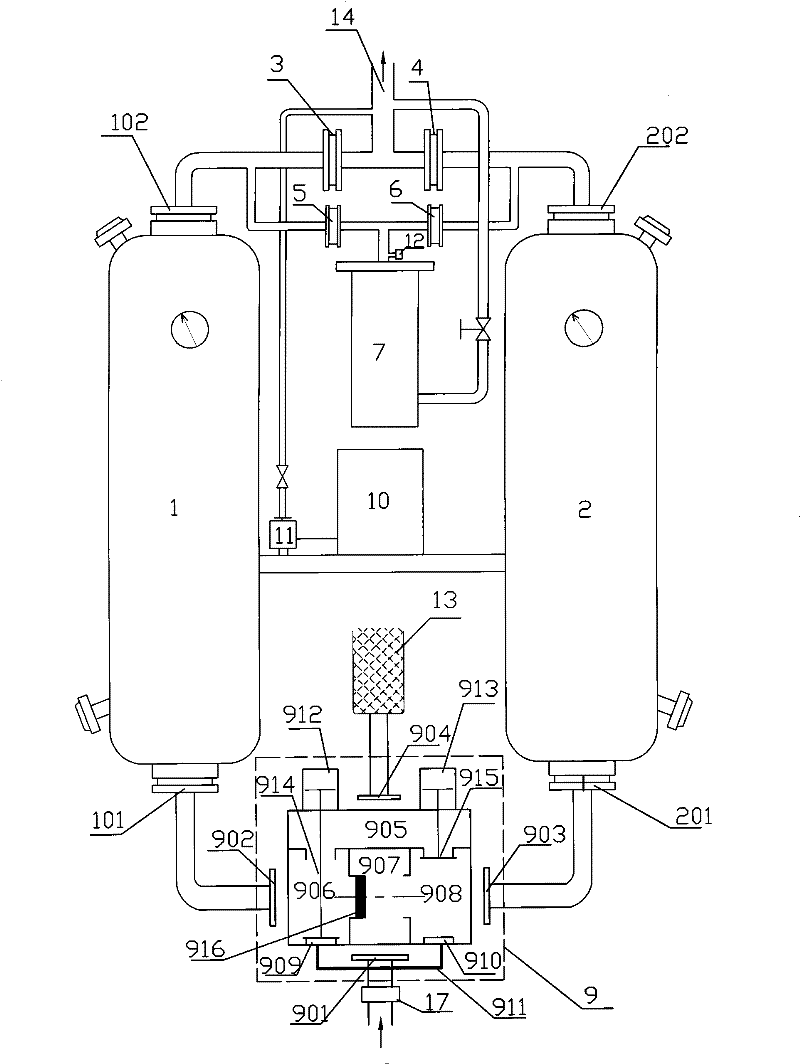

[0027] A heated adsorption dryer such as figure 1 As shown, it includes a first adsorption tower 1, a second adsorption tower 2, an adsorption dryer controller, a muffler 13, a heater 7, a first check valve 3, a second check valve 4, and a third check valve 5 , the fourth one-way valve 6, the intake gas path switching device 9 and connecting pipes, etc., the used intake gas path switching device is an integrated combined valve.

[0028] The controller of the adsorption dryer of the present invention includes the intake air path switching control device 9 and the central controller 10 (referred to as controller 10).

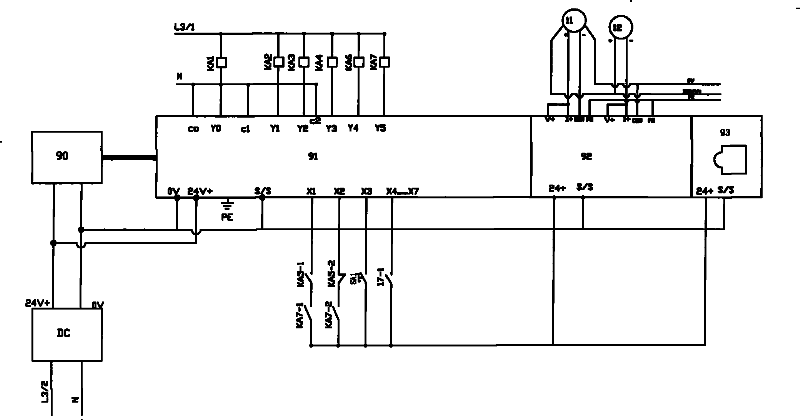

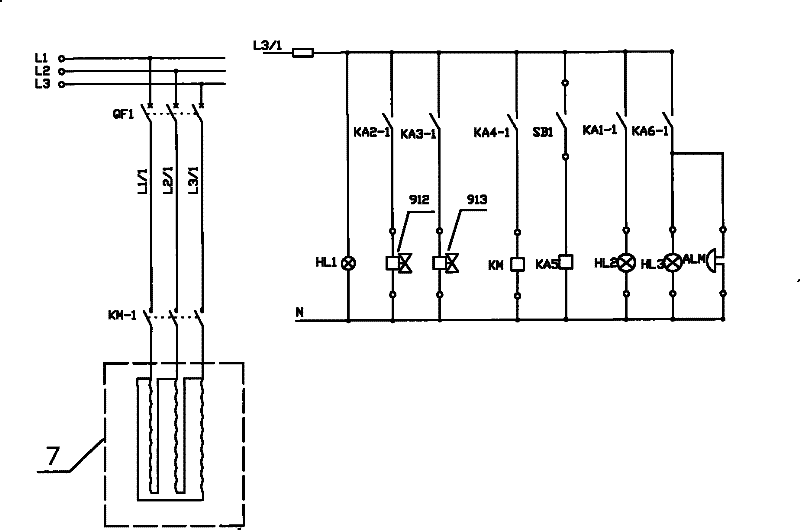

[0029] like figure 2 , 3 As shown, the controller 10 includes a programmable logic controller 91, an A / D conversion module 92, a communication module 93, a man-machine interface 90, intermediate relays, switches and the like. The output terminals Y0, Y1, Y2, Y3, Y4, and Y5 of the programmable logic controller 91 are respectively connected to the coils of the i...

Embodiment 2

[0041] Desiccant dryers without heaters, such as Figure 4 Shown: including adsorption first adsorption tower 1, second adsorption tower 2, adsorption dryer controller, muffler 13, first one-way valve 3, second one-way valve 4, bypass pipe 15, throttle orifice 16. Intake gas path switching device 9, the used intake gas path switching control device is four independent electric control valves.

[0042] like Figure 5 , 6 As shown, the controller of the adsorption dryer in this embodiment also includes the intake gas path switching control device 9 and the central controller 10 (referred to as controller 10).

[0043] The controller 10 includes a programmable logic controller 91, a man-machine interface 90, a communication module 93, intermediate relays and the like. The output terminals Y1, Y2, Y6 and Y7 of the programmable logic controller 91 are respectively connected to the intermediate relays KA2, KA3, KA8 and KA9.

[0044] The normally open contact KA2-1 of the interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com