Quartz wafer deep micropore processing equipment and method

A technology for processing quartz wafers and microholes, which is applied in the direction of microlithography exposure equipment, chemical instruments and methods, microstructure technology, etc., can solve the problem of charged particles charged by ion drilling, which cannot be solved well, and cannot be solved by quartz wafers. Processing of micro-holes, failure to meet the requirements of micro-electro-mechanical systems, etc., to achieve the effect of fast etching speed, easy implementation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

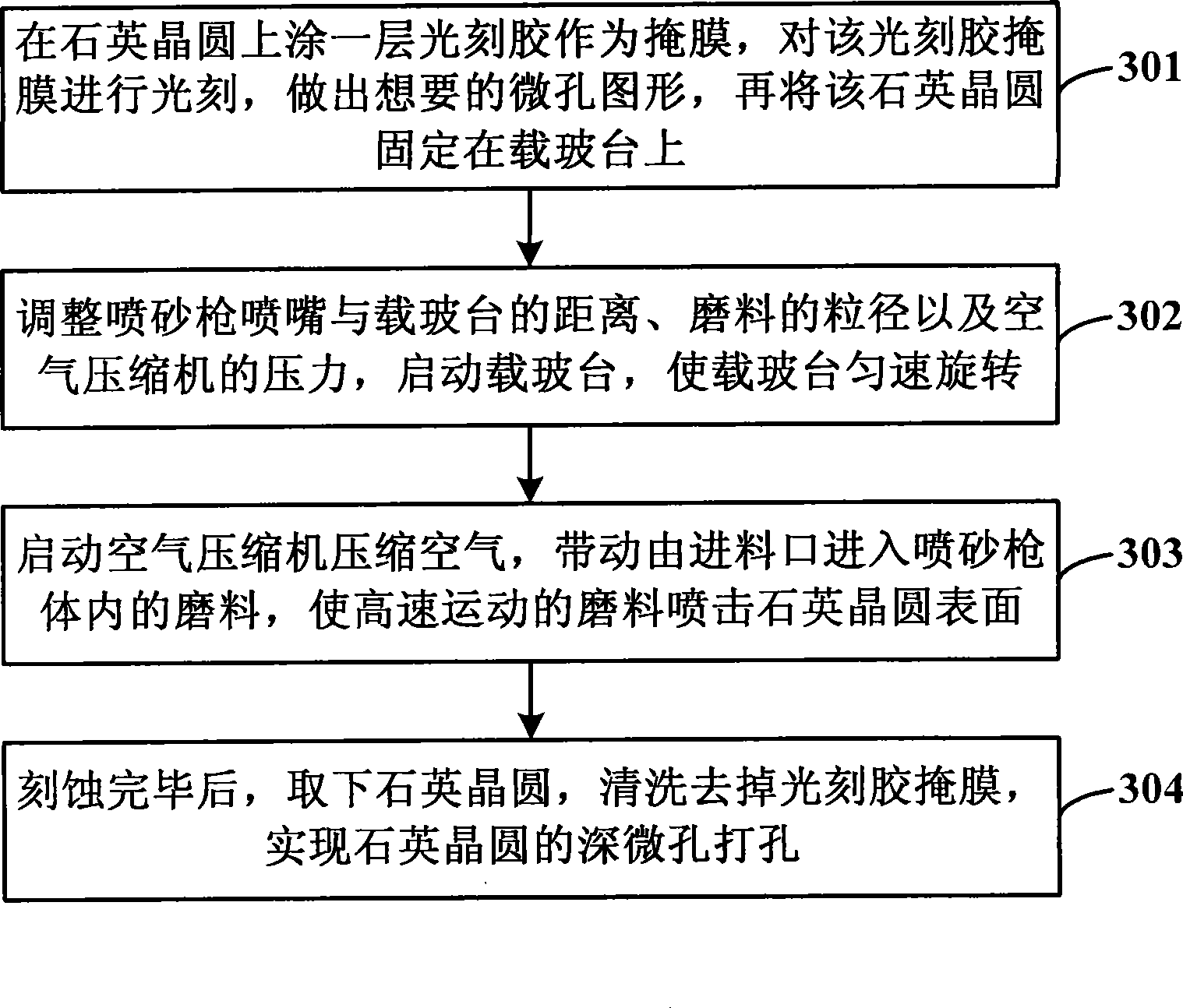

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

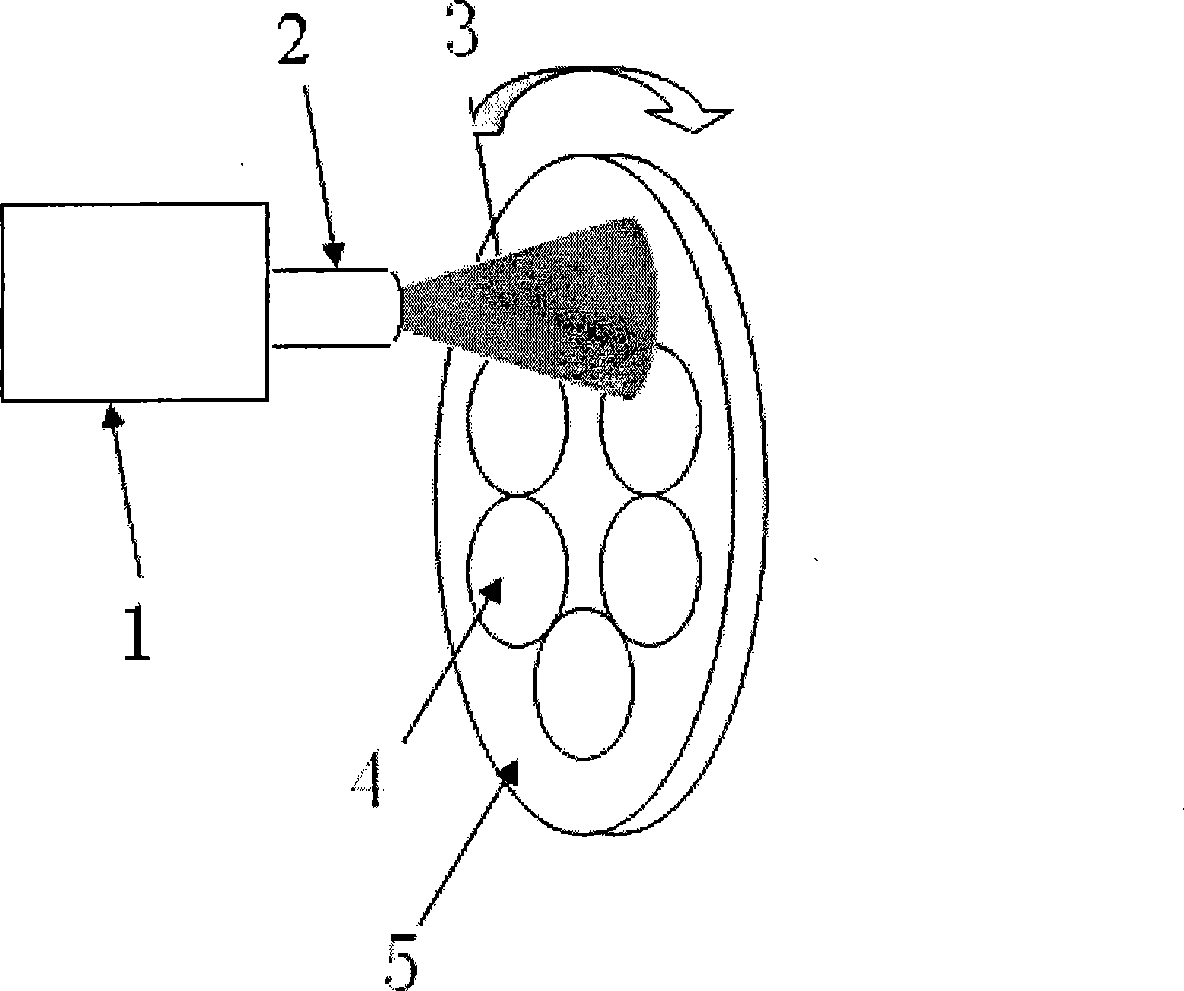

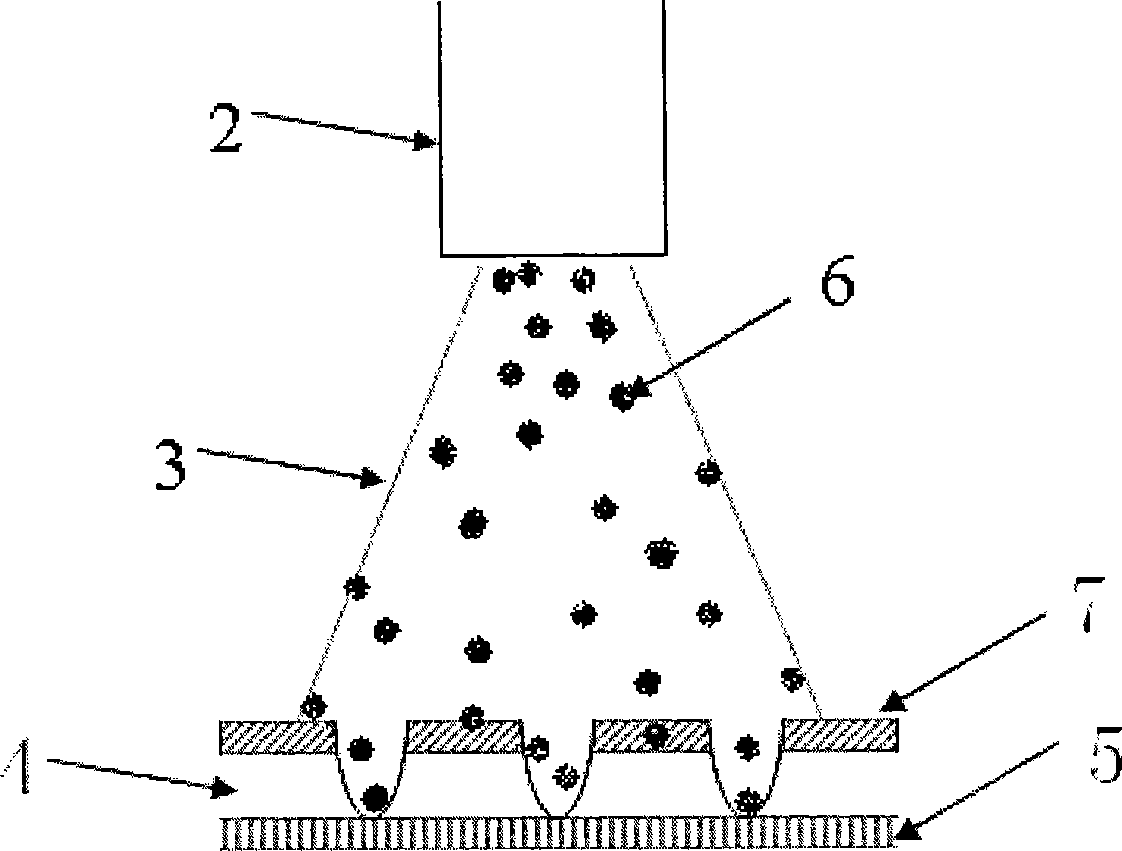

[0039] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the quartz wafer deep micro-hole processing equipment provided by the present invention, and the equipment includes an air compressor 1 , a sandblasting gun 2 and a glass stage 5 . The compressor 1 is connected to the sandblasting gun 2, and the compressor 1 delivers high-compressed air to the sandblasting gun 2, so that the abrasive in the sandblasting gun 2 is sprayed at a high speed on the quartz wafer placed on the glass stage 5, and the The high-speed moving abrasive hits the quartz material to achieve deep micro-hole processing on the quartz wafer.

[0040] The glass stage 5 is vertically placed and rotated at a constant speed when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com