Converter gas dry method pocket type purification and recovery process and system

A converter gas and dry process technology, applied in the field of gas purification, can solve the problems of sewage treatment, unstable system operation, large system resistance loss, etc., and achieve high purification efficiency, low operation and maintenance costs, and low operation resistance and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

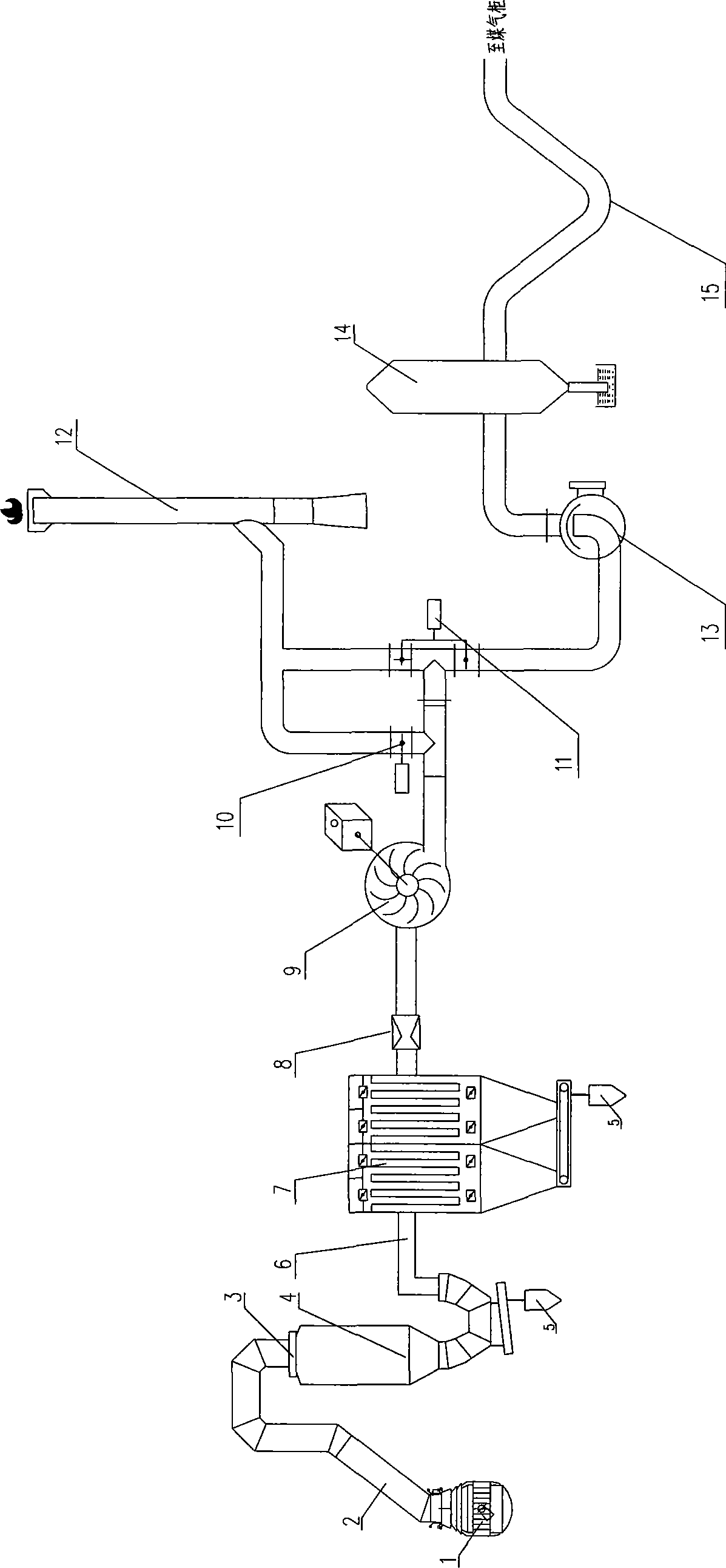

[0015] With reference to accompanying drawing, concrete implementation of the present invention is described further:

[0016] The vaporization cooling device 2 of the converter 1 is connected to the evaporative cooler 4 through the expansion joint 3, and the evaporative cooler 4 and the bag filter 7 are connected through a metal pipe 6; the piping system 6 behind the bag filter 7 is installed with Gas flow meter 8, gas blower complete set 9, bypass valve 10, three-way switching valve 11, release chimney 12, water seal check valve 13, gas cooler 14 and V-shaped water seal 15.

[0017] Converter 1 produces high-temperature dust-laden flue gas during oxygen-blowing smelting. The main component of flue gas is coal gas. The flue gas is cooled to 800-1000°C by vaporization cooling device 2, and dust-laden gas enters evaporative cooler 4 through expansion joint 3. It is atomized and cooled by a two-phase injection device composed of steam or nitrogen and water, and the gas temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com