Plane right-angle instrument for marking line

A pay-off instrument and right-angle technology, which is applied in the field of construction pay-off instruments for the rectangular main axis of construction engineering, can solve the problems of high manufacturing cost, long operation time, and difficult operation of theodolite, and achieve easy operation, easy processing, and improved work. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

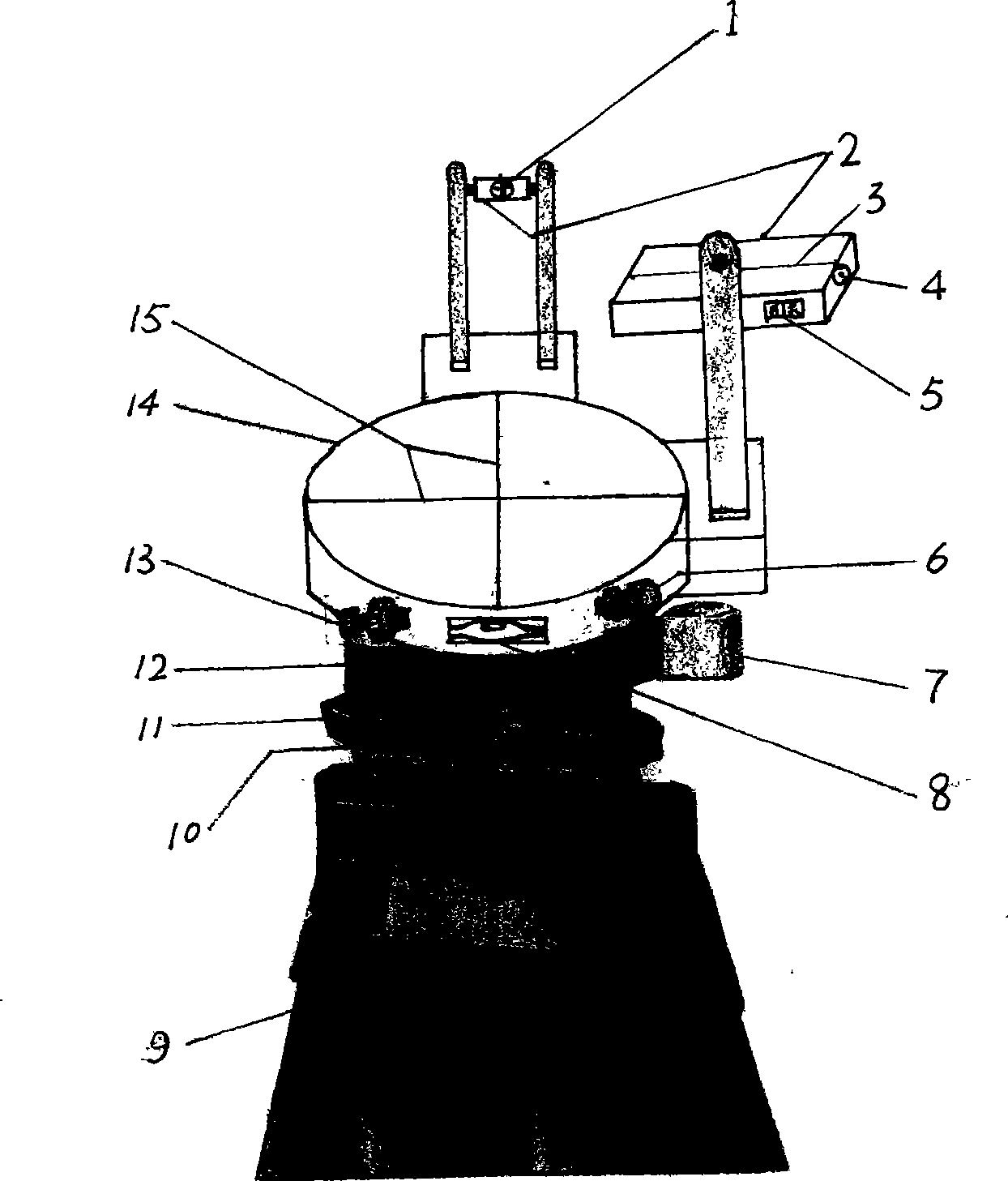

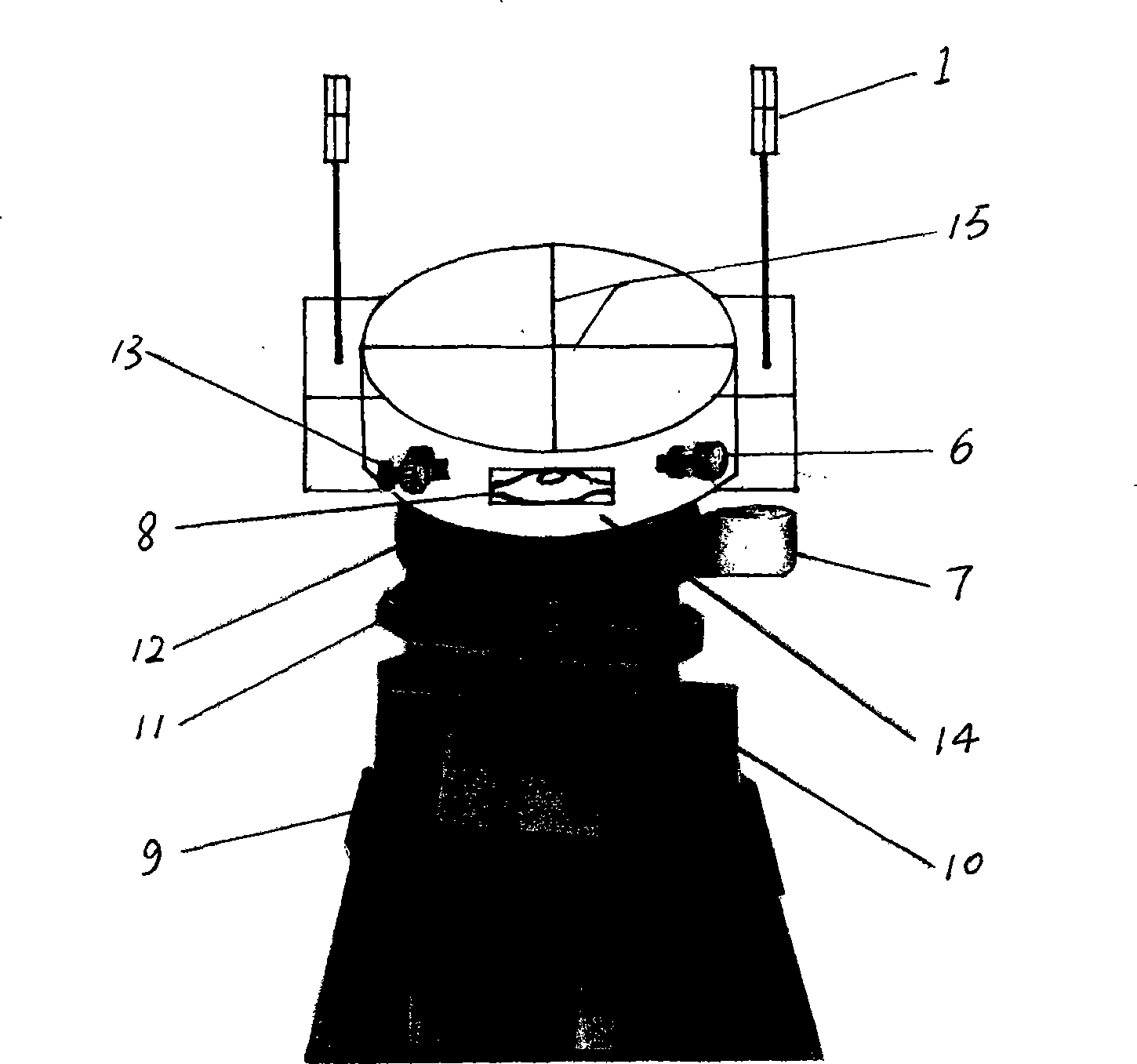

[0013] Such as figure 1 and figure 2 Shown: a plane right-angle pay-off instrument, including a laser transmitter body and two laser receiver bodies;

[0014] The main body of the laser emitter includes a cross mirror 1, a laser emitter 2, a sight line groove 3, an end point of the laser emission axis 4, a laser emitter switch 5, an optical plummet 6, a circular level 7, a tube level 8, Tripod 9, tripod center connection screw rod 10, angle screw 11, triangle base 12, horizontal brake fine-tuning bolt 13, top plate 14 and cross reticle 15; the tripod base 12 connects screw rod 10 through the tripod center Installed on the tripod 9, the bottom of the triangular base 12 is provided with three corner screws 11, the triangular base 12 is provided with a circular level 7, the top plate 14 is installed on the triangular base 12, and the top plate 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com