Viscous cosmetic

A cosmetic and viscous technology, applied in the direction of cosmetics, cosmetics, packaging cosmetics, etc., can solve the problems of unhygienic, viscous cosmetics pollution, etc., and achieve the effect of improving the coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] The present invention will be illustrated by examples below, but the present invention is not limited thereto.

[0048] Firstly, the push-out type container of the viscous cosmetic of the present invention, which can retrieve the contents, will be described.

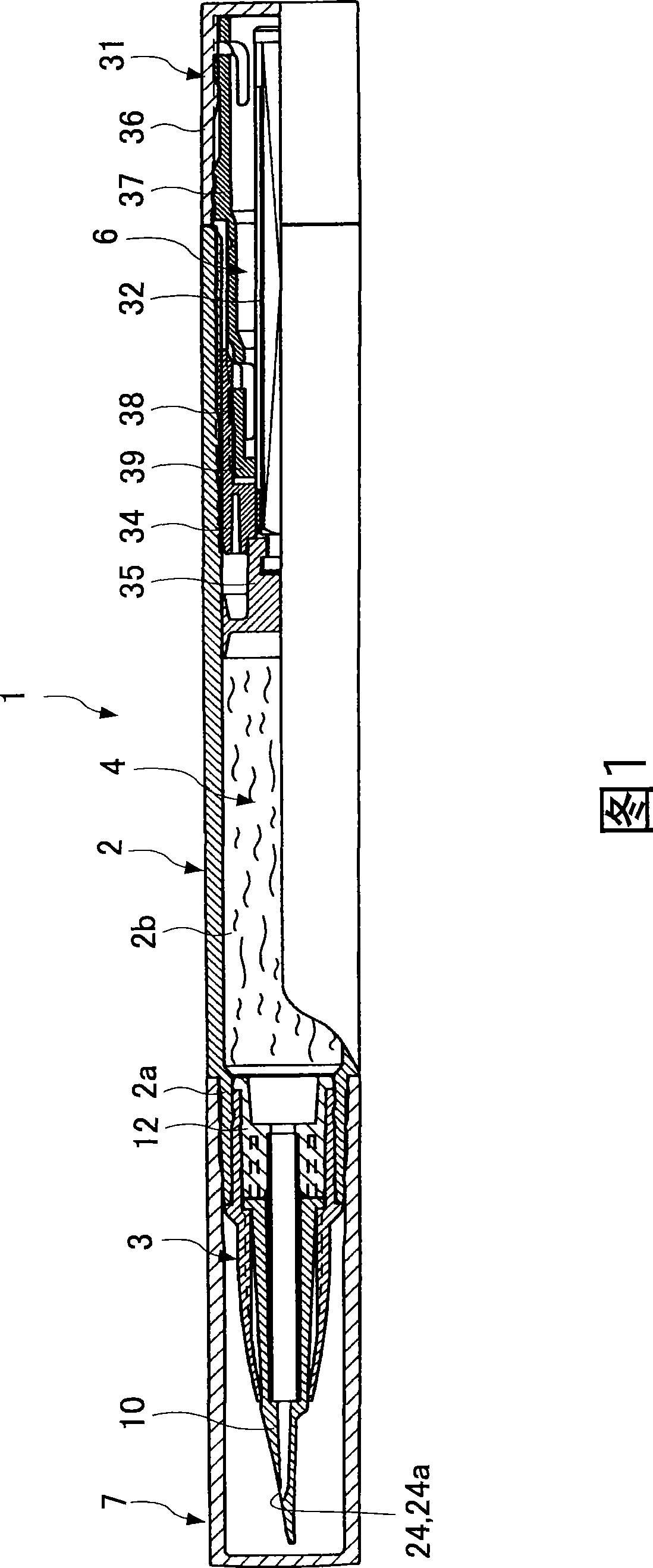

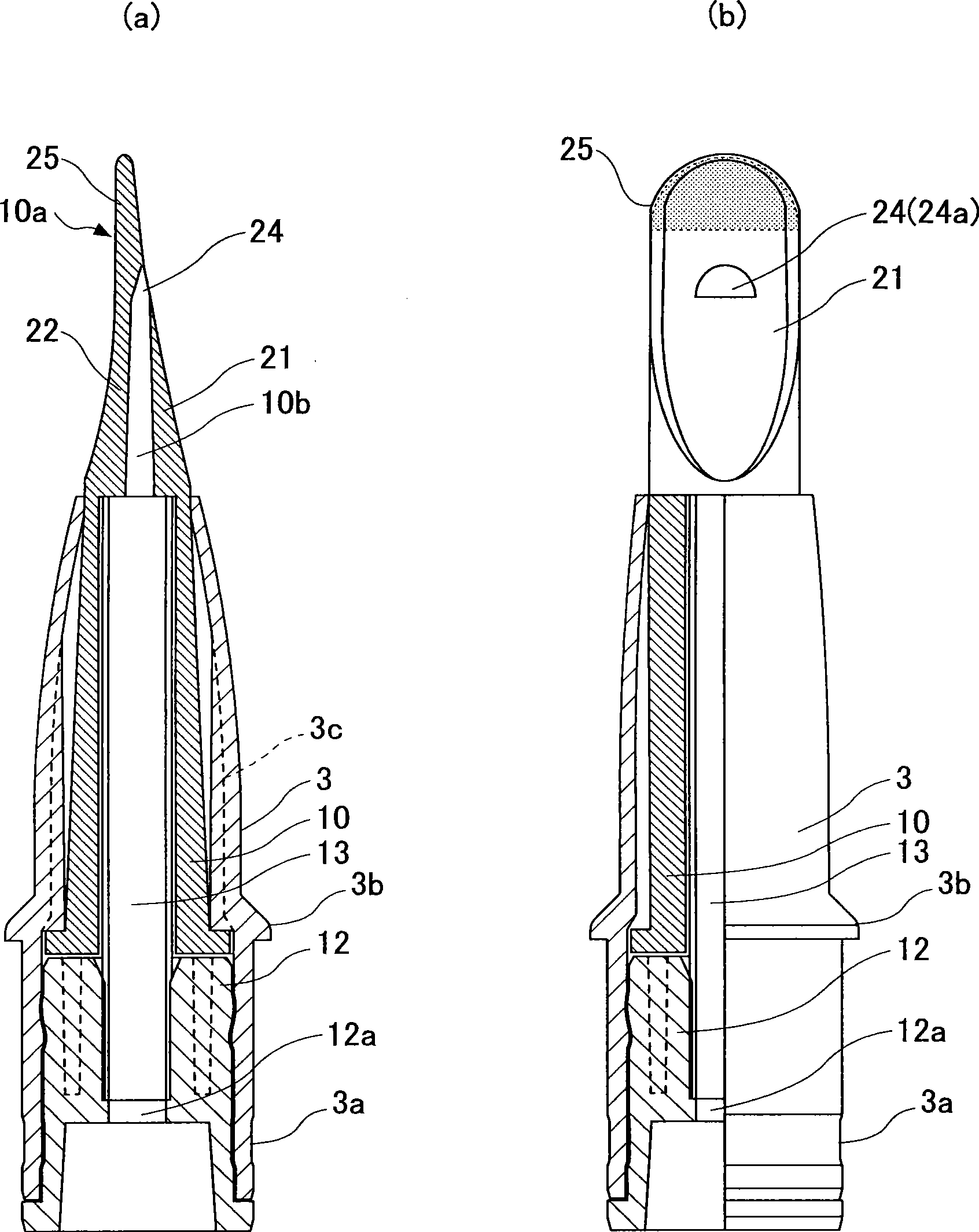

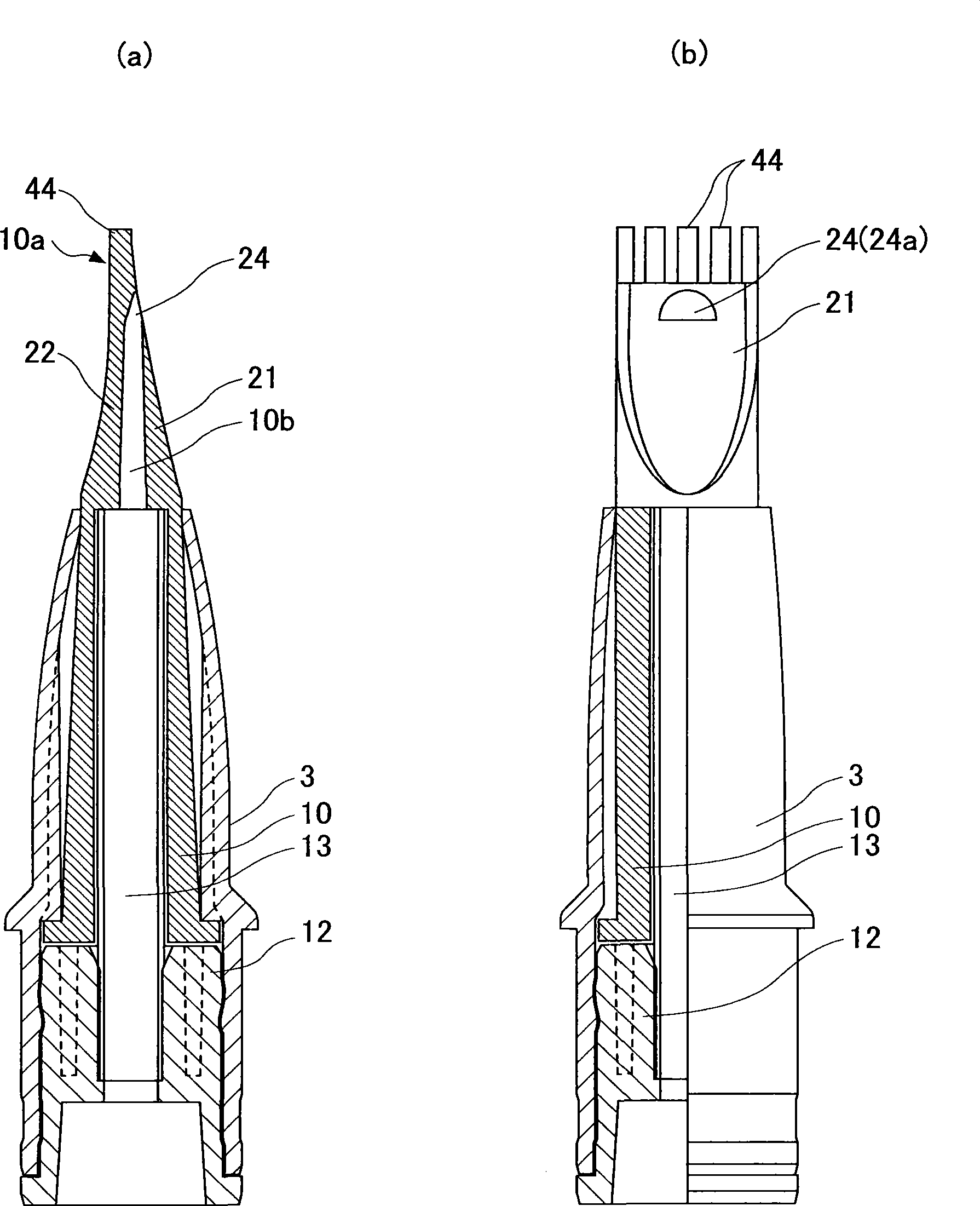

[0049] First, the embodiment when the viscous cosmetic of the present invention is pushed out from the container will be described with reference to FIG. 1 . Figure 2 to Figure 4 Various shapes of the coated body forming the coated portion will be described.

[0050] As shown in FIG. 1 , the viscous cosmetic 1 of the first embodiment has a liquid pressing structure (liquid pressing unit) 6 for pressurizing the viscous cosmetic 4 inside the main body 2, and the front end of the liquid pressing structure is provided as Piston body 35 of the inner disc. That is, the piston body 35 is formed to supply the viscous cosmetic 4 to the application body 10 according to the pressing of the liquid pressing structure 6 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com