A Submerged Biased Arc Welding Method

A welding method and offset arc technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high assembly precision of weldments, inability to perform bottom welding, and unsuitable for welding thin plates, etc., and achieve easy short arc welding. Welding, not easy to weld through or collapse, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0040] The following examples are non-limiting examples of the invention.

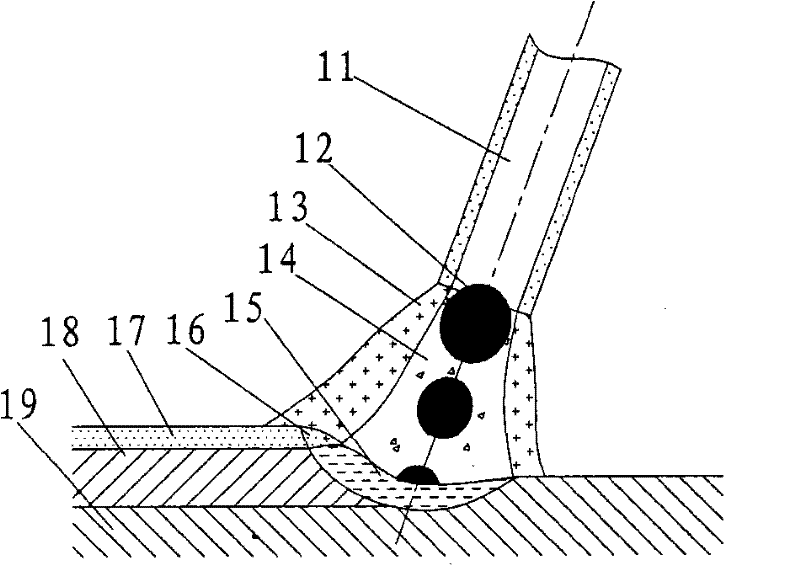

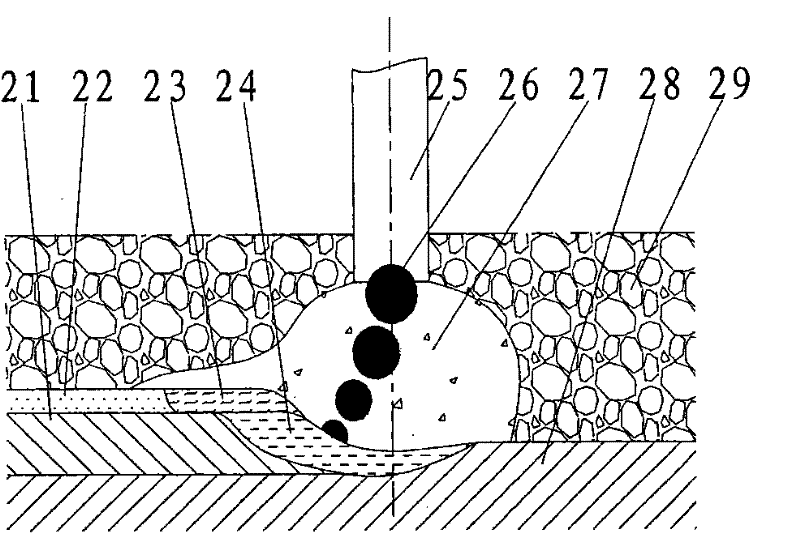

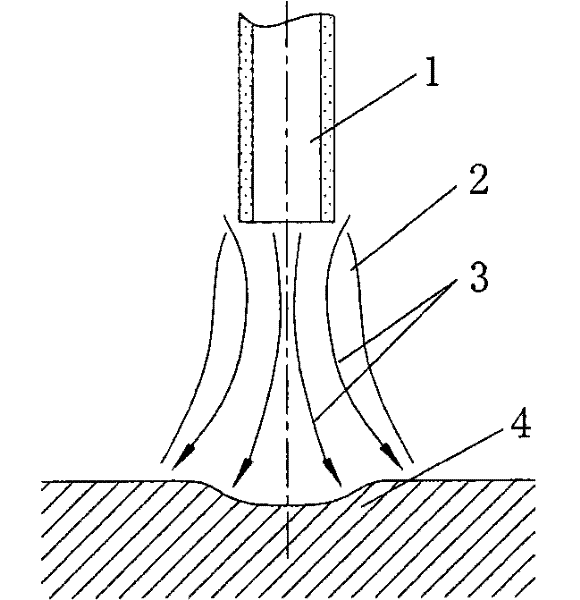

[0041] like Figure 7 As shown, the welded joint 72 positioned to be welded is placed horizontally. In this embodiment, the weldment 72 to be welded is a Q235 low-carbon steel plate with a thickness of 10 mm or 12 mm, and the length of the weld seam is 300 mm. According to the performance requirements of the material joint of the weldment 72, and according to the welding material selection principle of general welding technology, the welding rod of model E4303 is selected, and its diameter can be Φ3.2mm, Φ4.0mm or Φ5.0mm.

[0042] The welding rod 74 is placed close to the welding gap along the top of the welding gap, the placement direction of the welding rod 74 is the extension direction of the welding gap, and the coating surface of the welding rod 74 is fully cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com