Milling and drilling machine comprising a pallet exchanger

A pallet exchange, program-controlled technology, applied in the direction of manufacturing tools, metal processing machinery parts, other manufacturing equipment/tools, etc., can solve the problems of lifting mechanism pollution, failure, failure, etc., to prevent fluid pollution and reduce error quotas , the effect of preventing debris accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

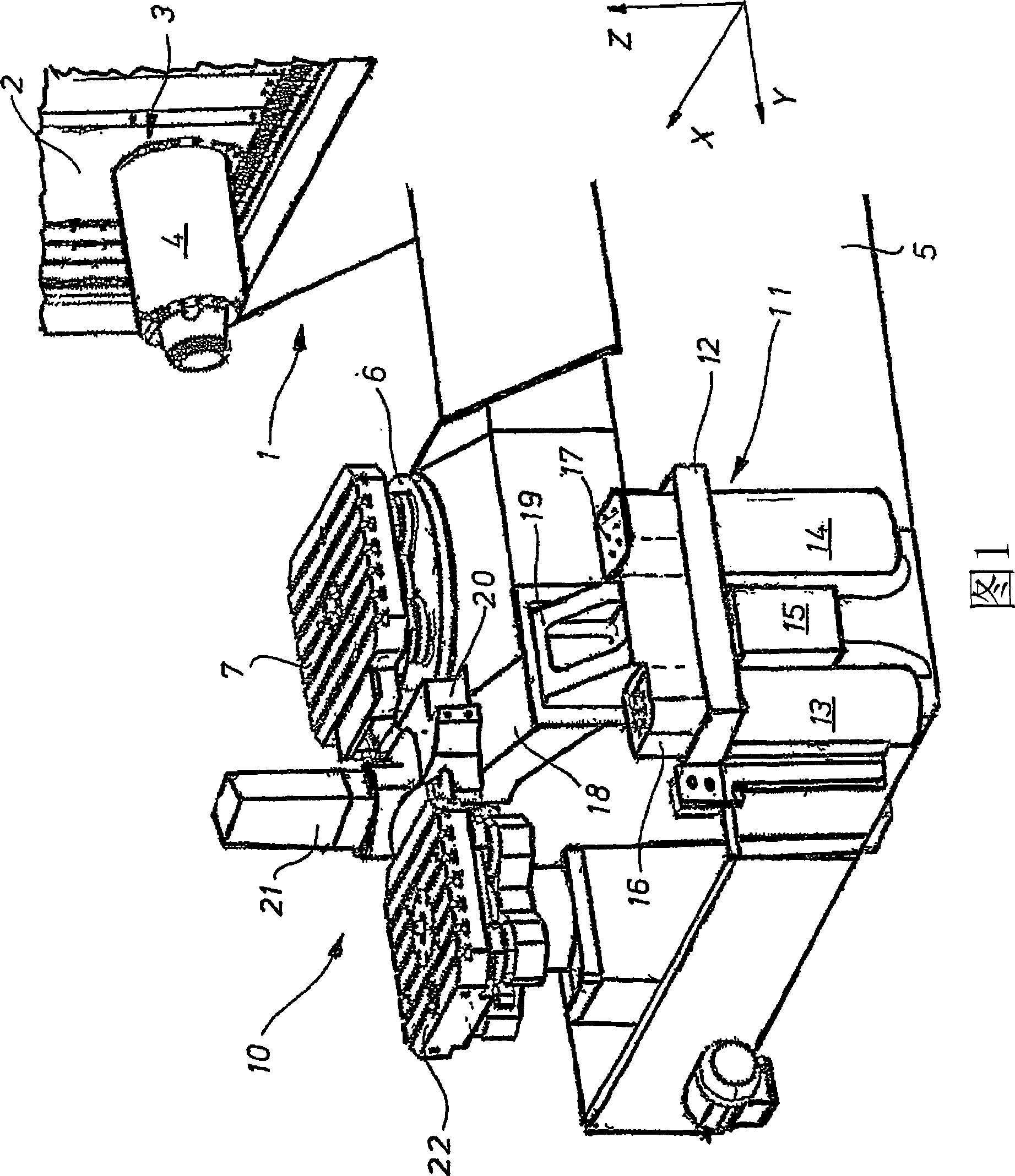

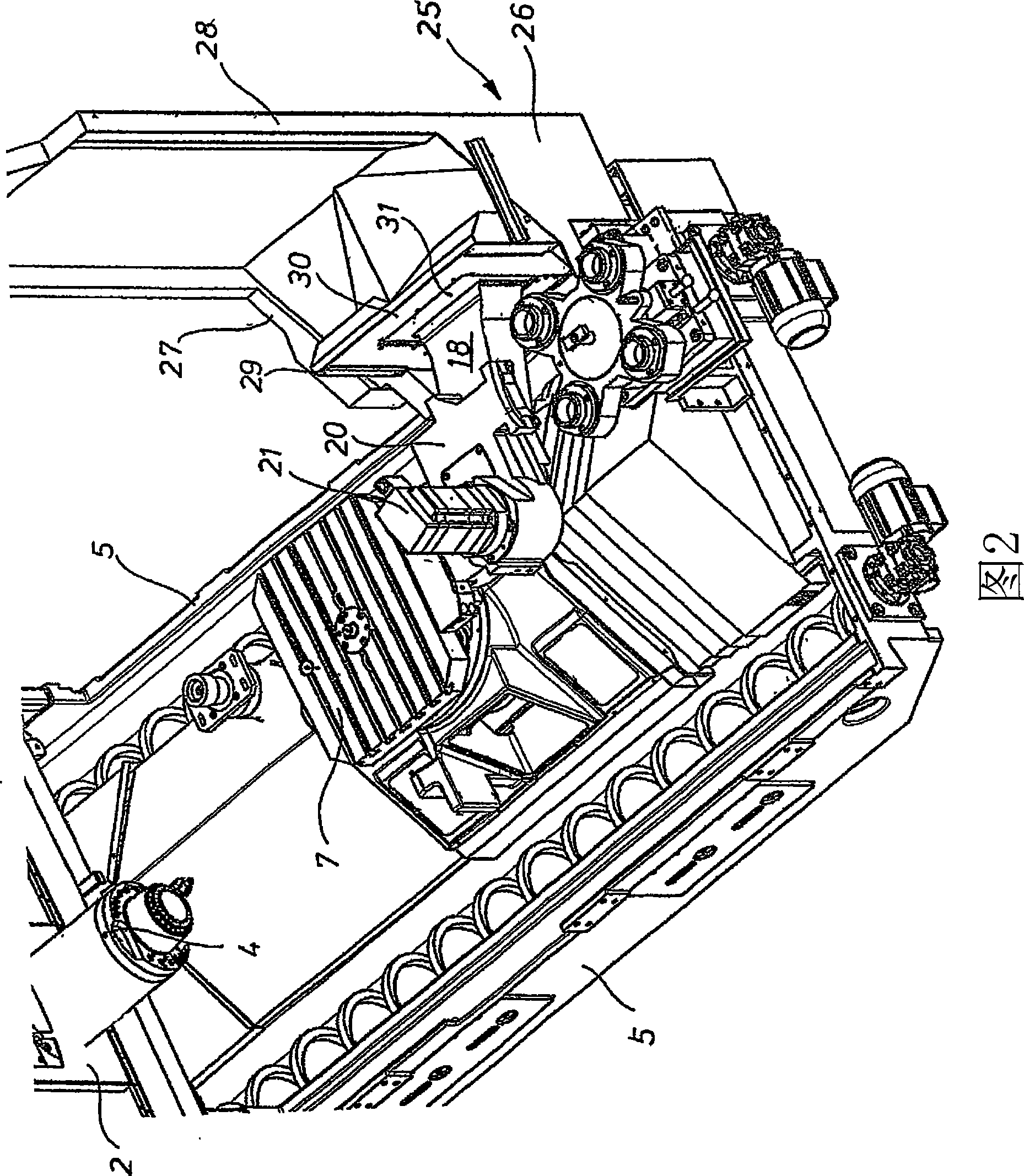

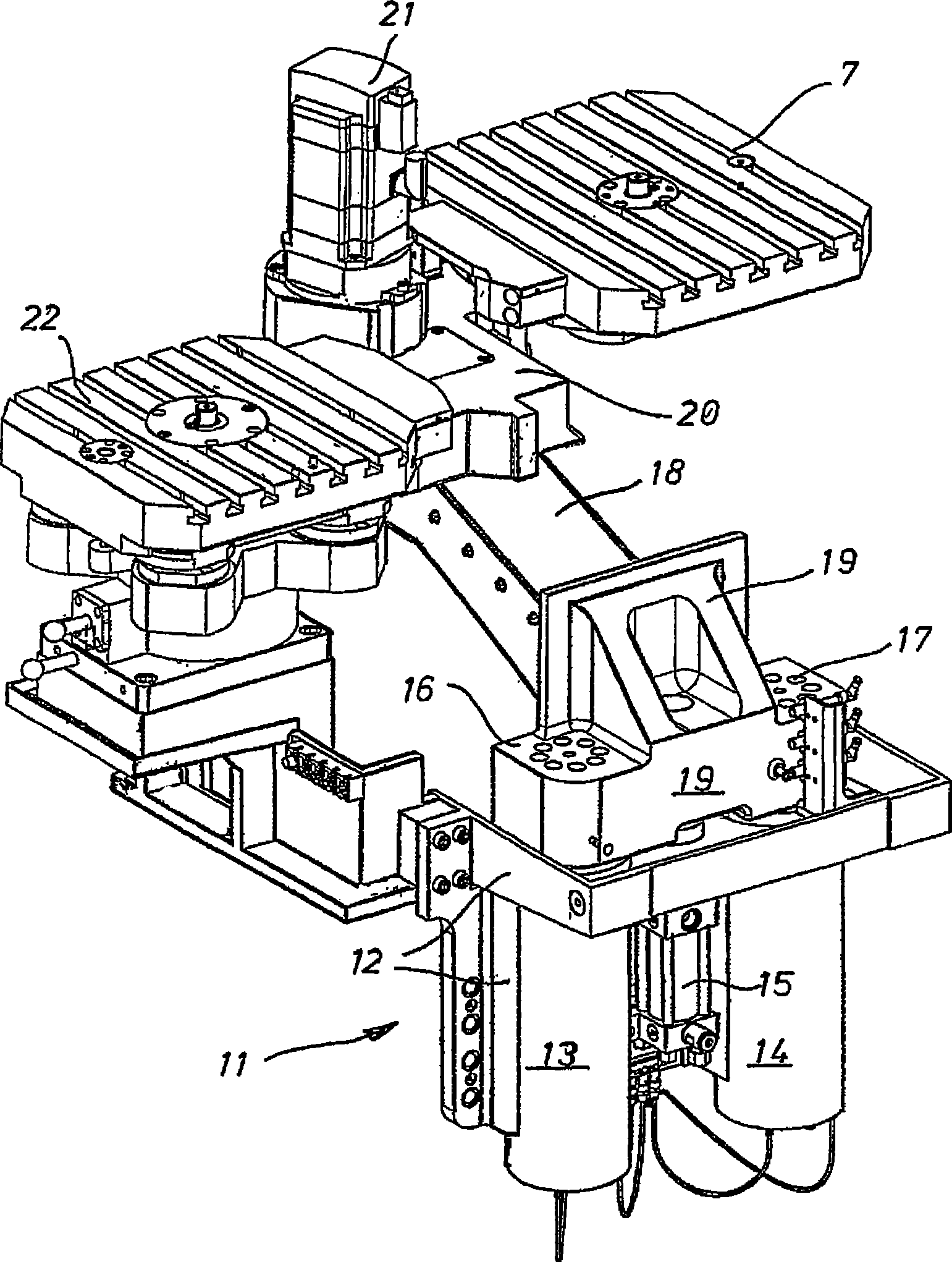

[0015] The front part of the milling-drilling machine shown in Figures 1 and 2 comprises a machining column 1 (not shown in detail in the present case) covered by a steel sheet frame 2 provided with a milling head comprising a horizontal milling head in the present case 4 work units 3. The working unit 3 can be moved along the coordinate axes X and Y by being driven by a motor. A bed 5 is installed in front of the processing column 1 , and a workpiece carrier 6 including a workpiece pallet 7 is arranged on the bed. The workpiece carrier 6 together with the pallet 7 can be moved by the motor in the longitudinal direction of the bed 5 , ie along the coordinate axis Y.

[0016] At the left end portion of the bed 5 in FIG. 1, a pallet exchange device 10 is provided, which will be described in more detail below. The pallet changer detailed in FIGS. 1 to 3 comprises a lifting mechanism 11 arranged at the side walls of the bed 5 and comprising a load carrying mechanism 12 . In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com