Method for repairing blast furnace cooling stave

A technology for cooling staves and blast furnaces, applied in the direction of cooling devices, etc., can solve problems such as affecting blast furnace production, wasting manpower, material resources, and threatening blast furnace safety production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The present invention will be further described below in conjunction with the accompanying drawings.

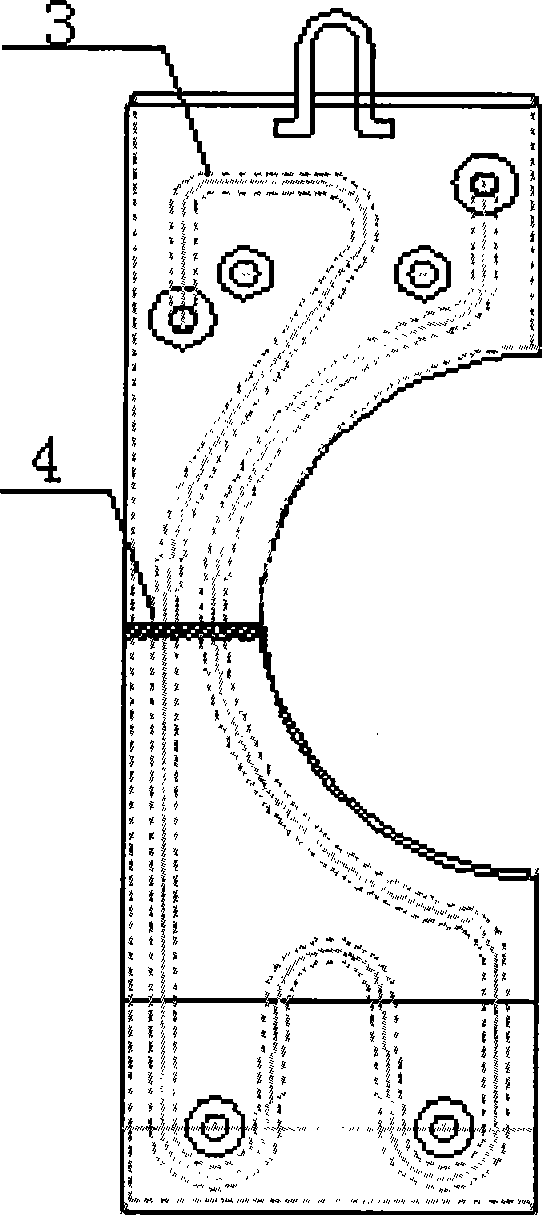

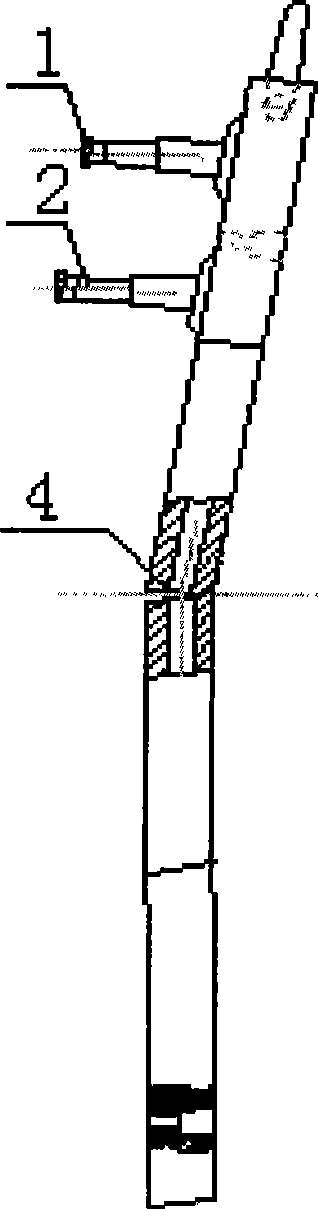

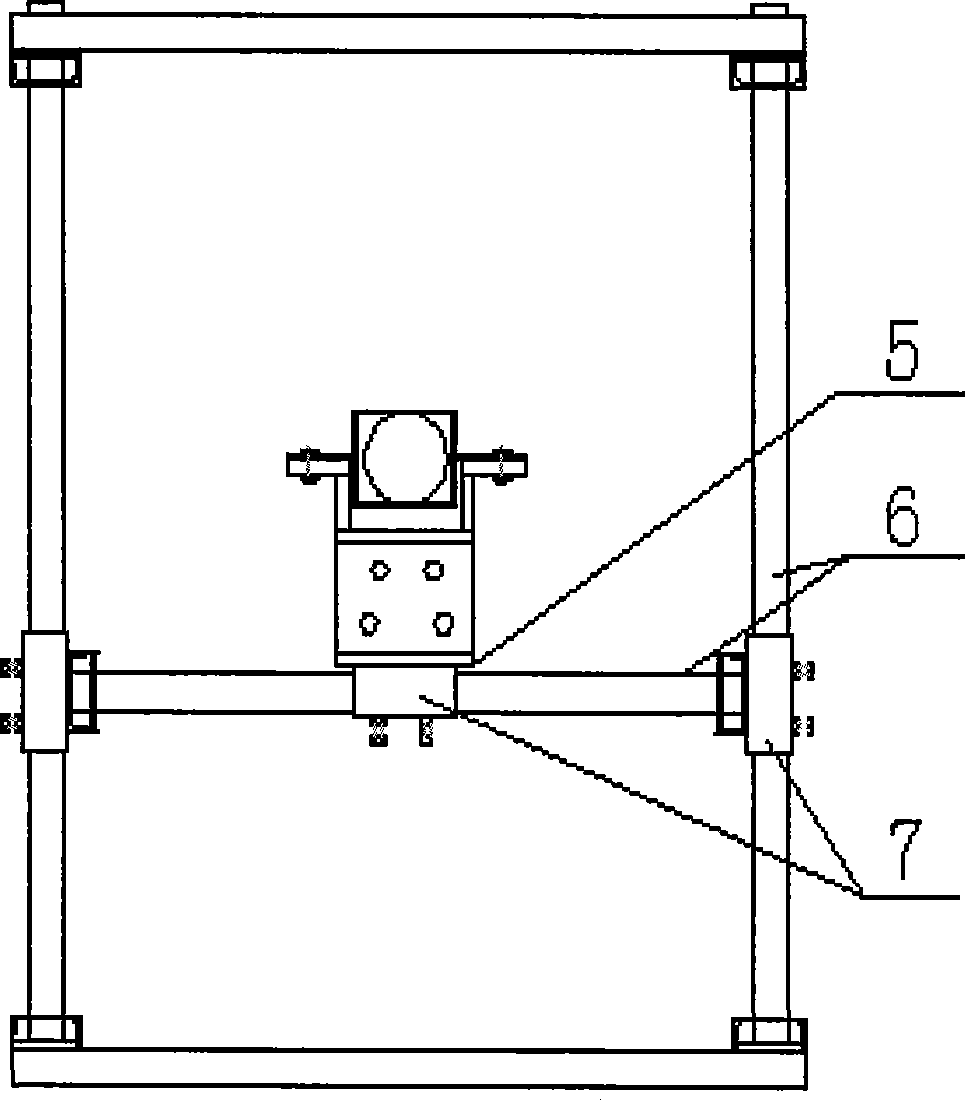

[0019] The first step is preparatory work. according to figure 1 , figure 2 The shape of the stave and the fractured part 4 are shown, which are made in advance image 3 , Figure 4 Power drill stand shown.

[0020] The second step is to drill holes. Cut off the blast furnace skin 11 after the blast furnace is shut down, exposing such as figure 1 Damaged staves shown, according to Figure 5 As shown, the electric drill stand is welded and fixed to the blast furnace skin 11 through the connecting device 12 . according to Figure 6 As shown, the position of the serpentine pipe 3 in the stave is calibrated according to the stave manufacturing drawings. At the fractured part 4 of the stave, drill holes 17 and 18 with a φ20mm drill bit 9 to find the position of the serpentine pipe 3 in the stave. Since there is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com