Ultra-resolution dual shaft differential confocal measurement method and device

A two-axis differential confocal and super-resolution technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem that the size of the objective lens and the resolution of the system cannot be well balanced, and there is no absolute position aiming and bipolar Tracking, which is not conducive to eliminating the common mode noise of the light intensity drift of the light source, etc., to achieve the effect of improving system resolution, improving linear range, and improving anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

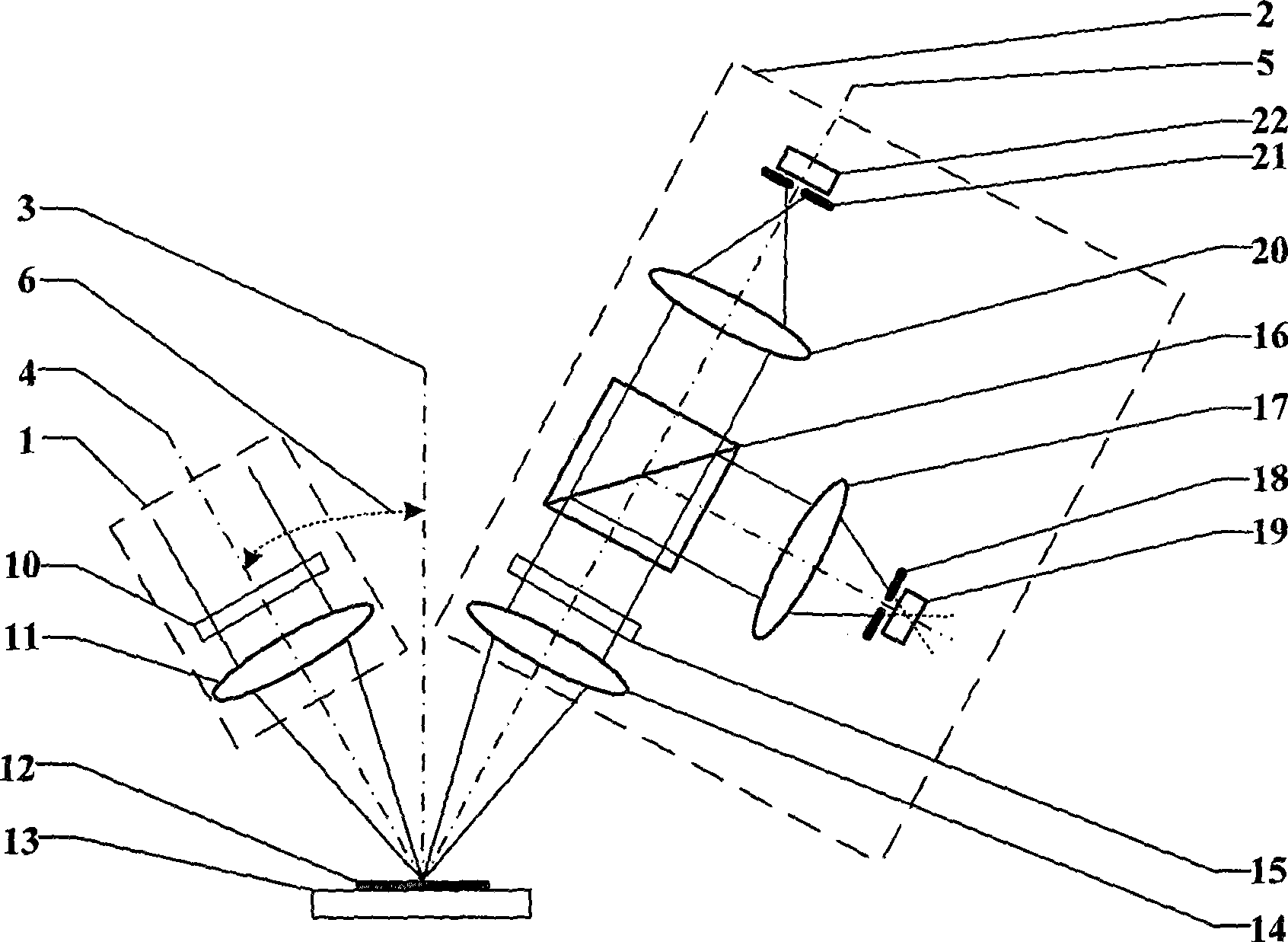

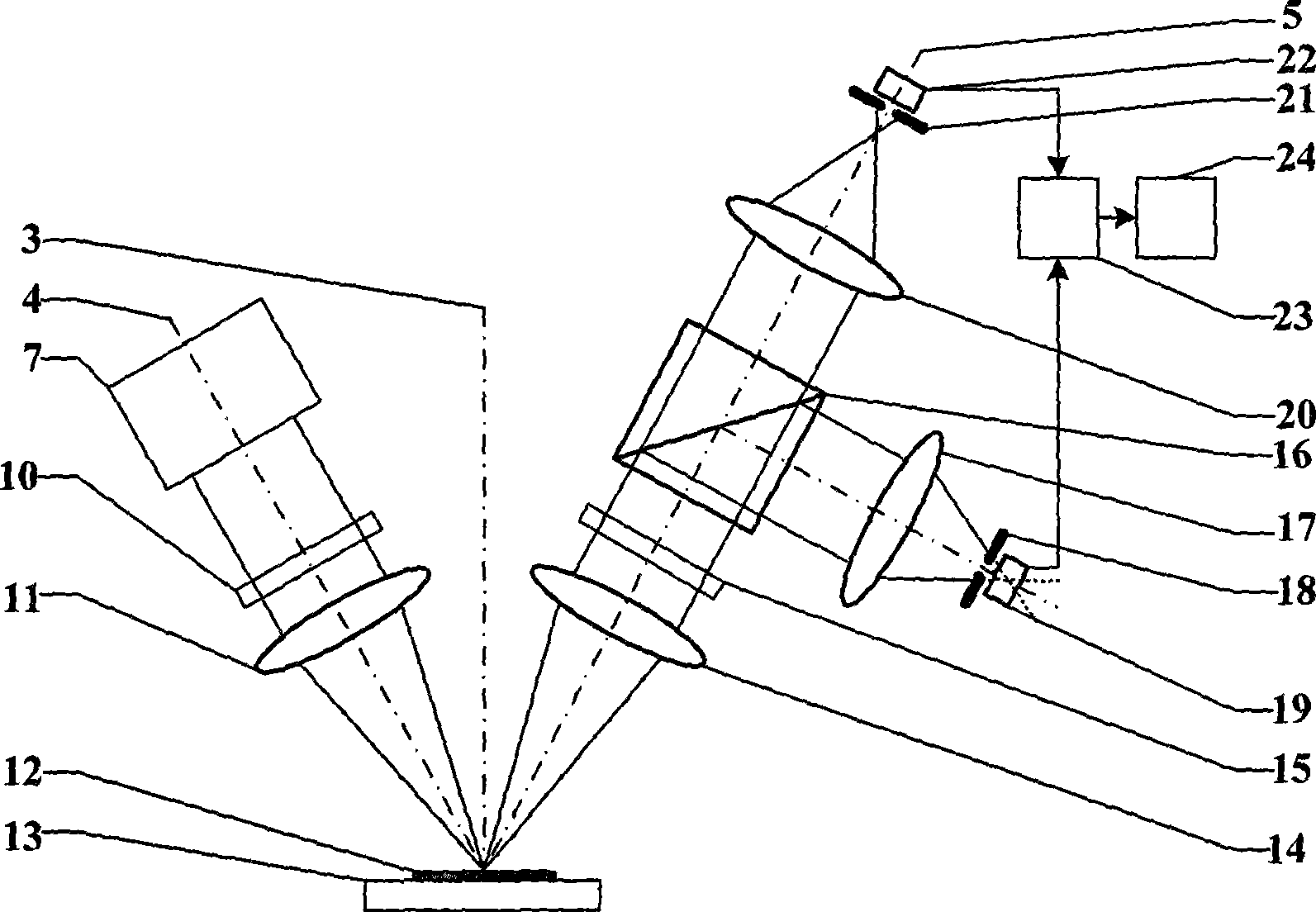

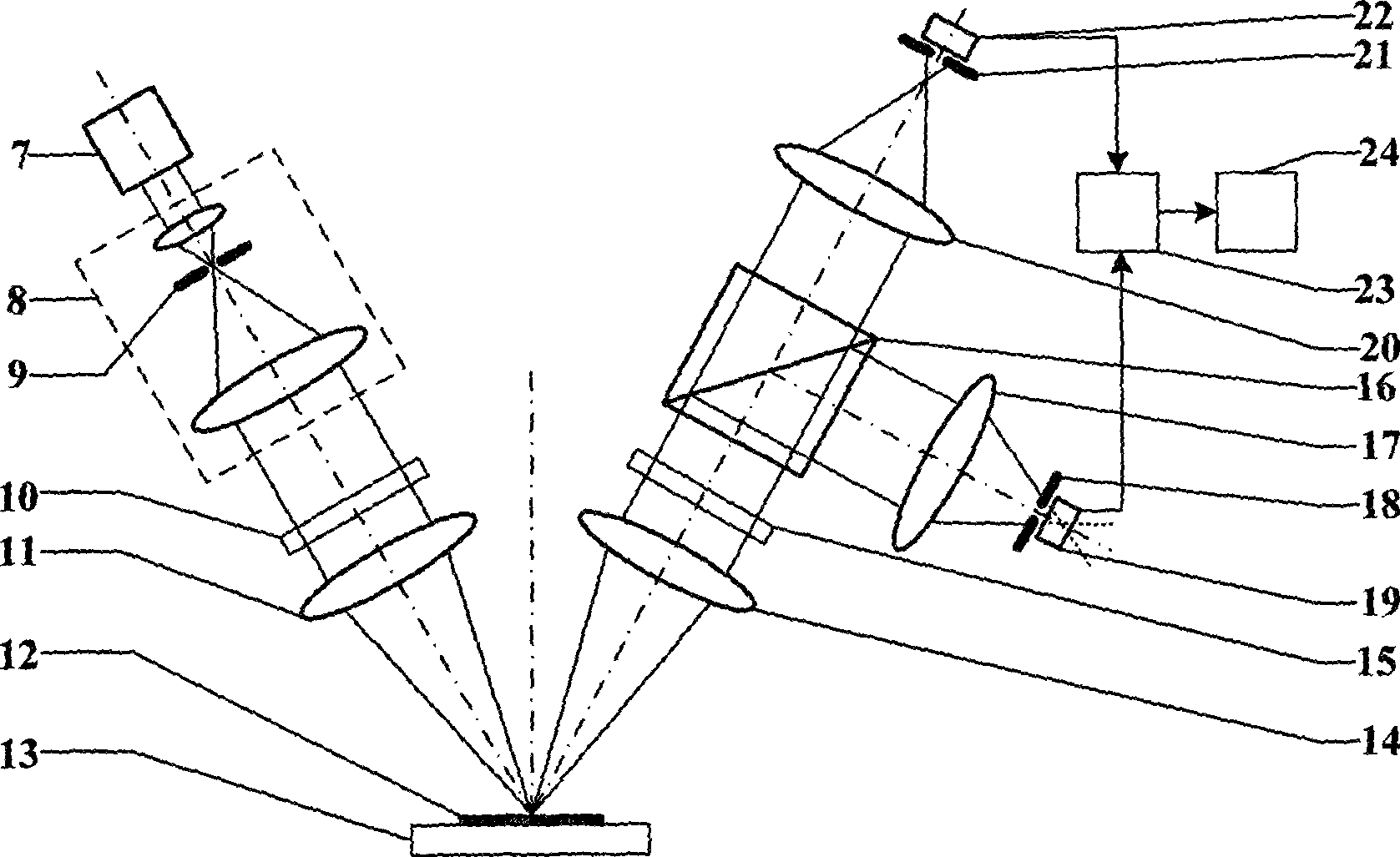

[0044] The present invention will be further described below in conjunction with drawings and embodiments.

[0045] Such as image 3 As shown, a super-resolution two-axis differential confocal measurement method, the measurement steps are:

[0046] First, the light source 7 (wavelength λ) is turned on, and the outgoing light is expanded into parallel light through the beam expander system 8 containing the spatial filter pinhole 9, and the parallel light is filtered and shaped by the pupil filter 10 at the illumination end, and then focused by the illumination objective lens 11 The surface of the measured sample 12 placed on the micro-displacement worktable 13 is reflected into the measurement objective lens 14, emerges as parallel light, and is filtered and shaped by the pupil filter 15 at the measurement end.

[0047] The light beam emitted by the pupil filter 15 at the measuring end is divided into two beams by the beam splitter 16, passes through the first collecting mirro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com