Computer simulation assembling method for steel structure assembly

A computer and steel structure technology, applied in the field of computer simulation of steel structure component assembly method manufacturing, can solve the problems of hidden dangers of operation safety, high labor intensity and high cost, and achieve the effects of improving efficiency, saving resources and strengthening competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

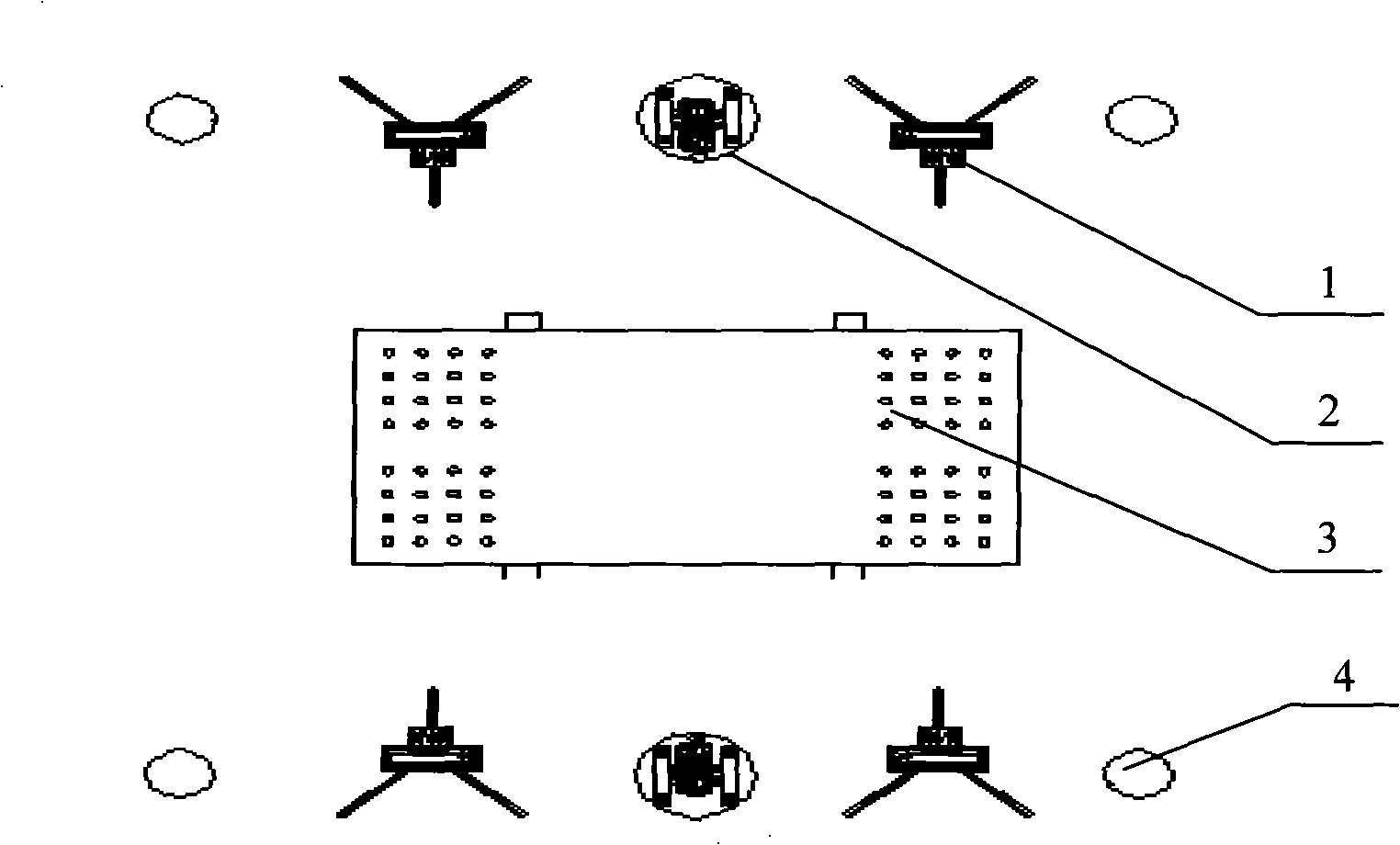

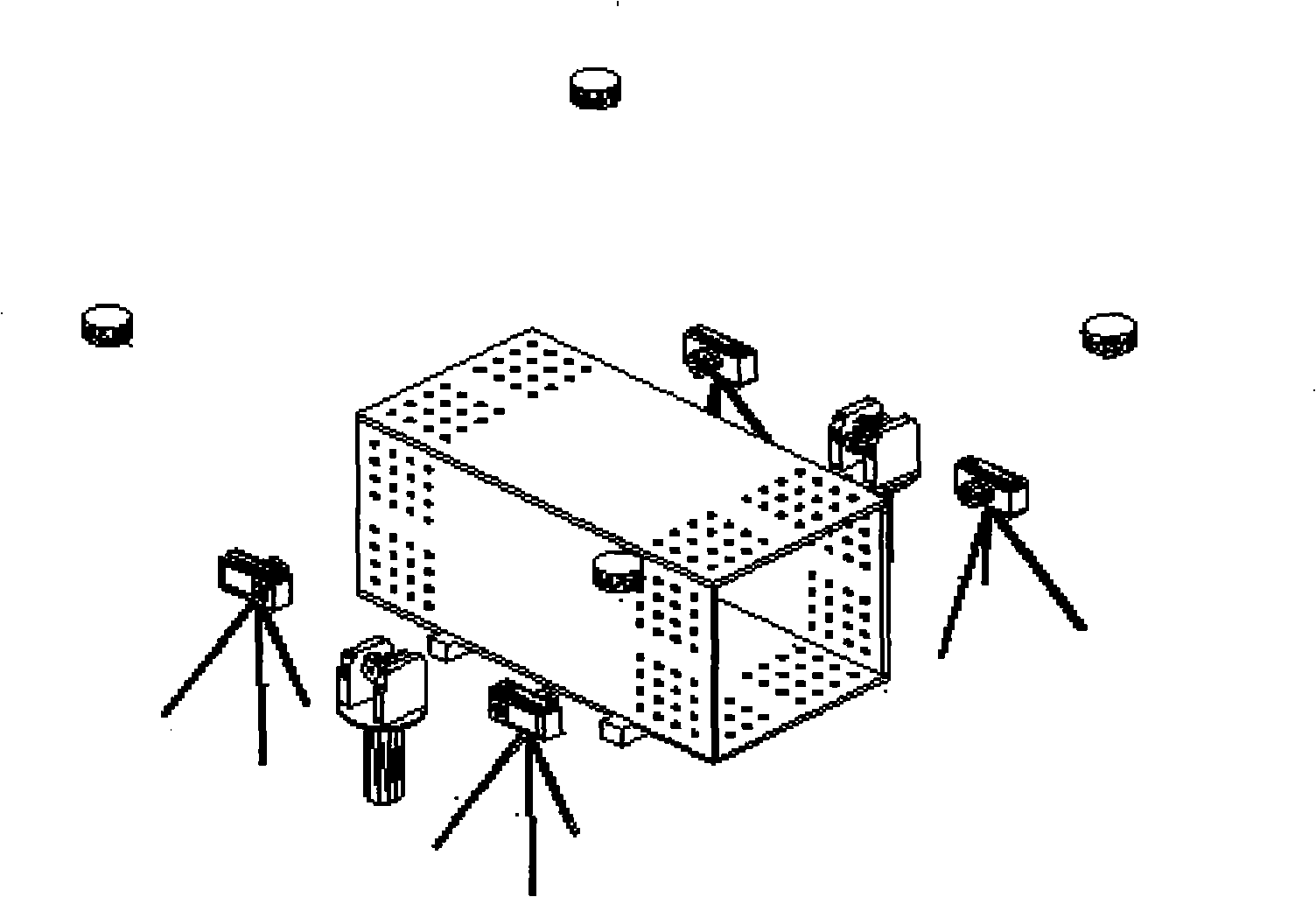

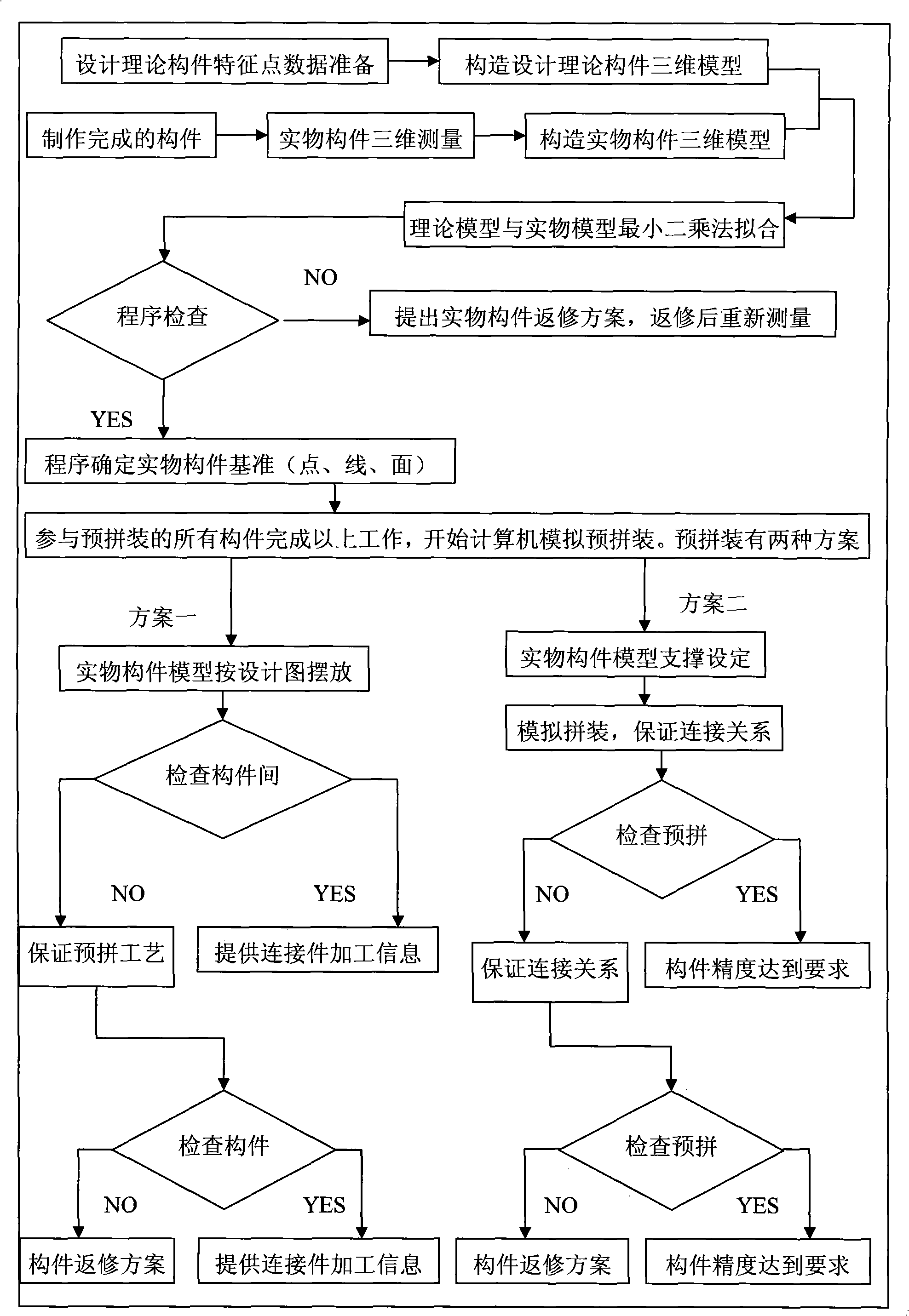

[0029] Embodiment 1: with reference to attached Figure 1~3. The computer simulated assembly method of steel structure components is used to perform three-dimensional measurement of the manufactured components, use the measurement data to construct component models in the computer, simulate and assemble the component models in the computer, and perform assembly interference checks on the computer, analyze assembly accuracy, Obtain the information required for the processing of component connectors: (1) Measuring system: use one or several digital photo measuring instruments to perform three-dimensional measurement of the measured component, the end face size, edge, and hole group of the component, and the laser tracking measuring instrument realizes The measurement of the relationship between the local groups measured by the digital photometer, and the coordinate conversion calculation of the above two measurement data, and finally realize the three-dimensional measurement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com