Separator for non-aqueous rechargeable lithium battery

A technology for recharging and lithium batteries, applied to secondary batteries, battery pack components, circuits, etc., can solve problems such as the deterioration of rechargeable batteries without consideration, and achieve the effect that it is not easy to deteriorate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

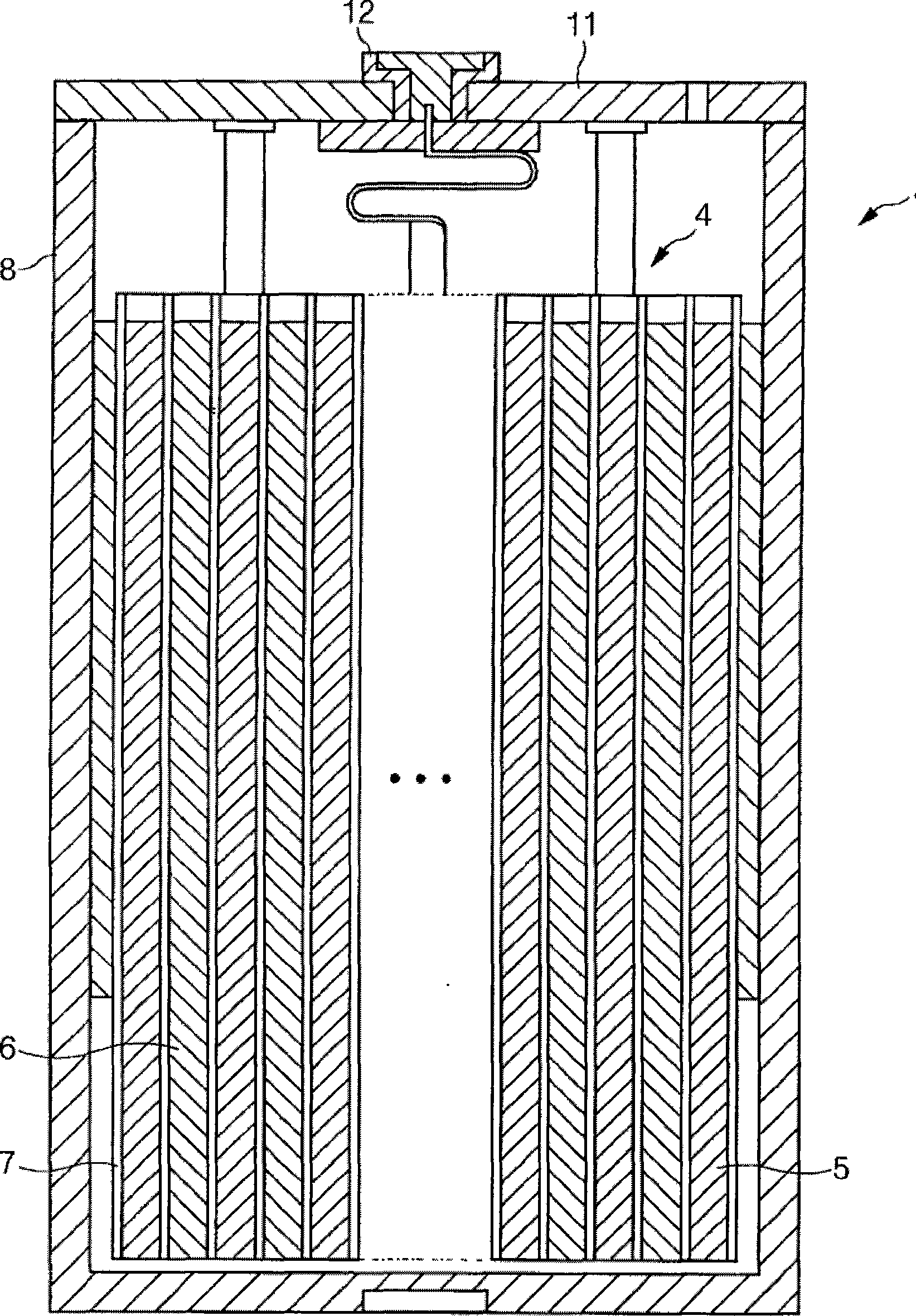

[0067] 3 parts by weight of N-methyl-2-pyrrolidone solution, 95 parts by weight of LiCoO 2 and 2 parts by weight of conductive carbon were mixed to provide positive electrode slurry. The positive electrode slurry was uniformly coated on a 15 μm thick Al foil and dried to provide a positive electrode. LiCoO 2 : Conductive carbon: The weight ratio of polyvinylidene fluoride is 95:2:3.

[0068] A mixture of lithium vanadium oxide (LVO) powder and carbon material powder is used as an anode active material. 90 parts by weight of the mixture were mixed with 10 parts by weight of polyvinylidene fluoride as a binder, and dispersed in N-methyl-2-pyrrolidone to provide negative electrode slurry. The negative electrode slurry was uniformly coated on a 20 μm thick copper foil and dried to provide a negative electrode.

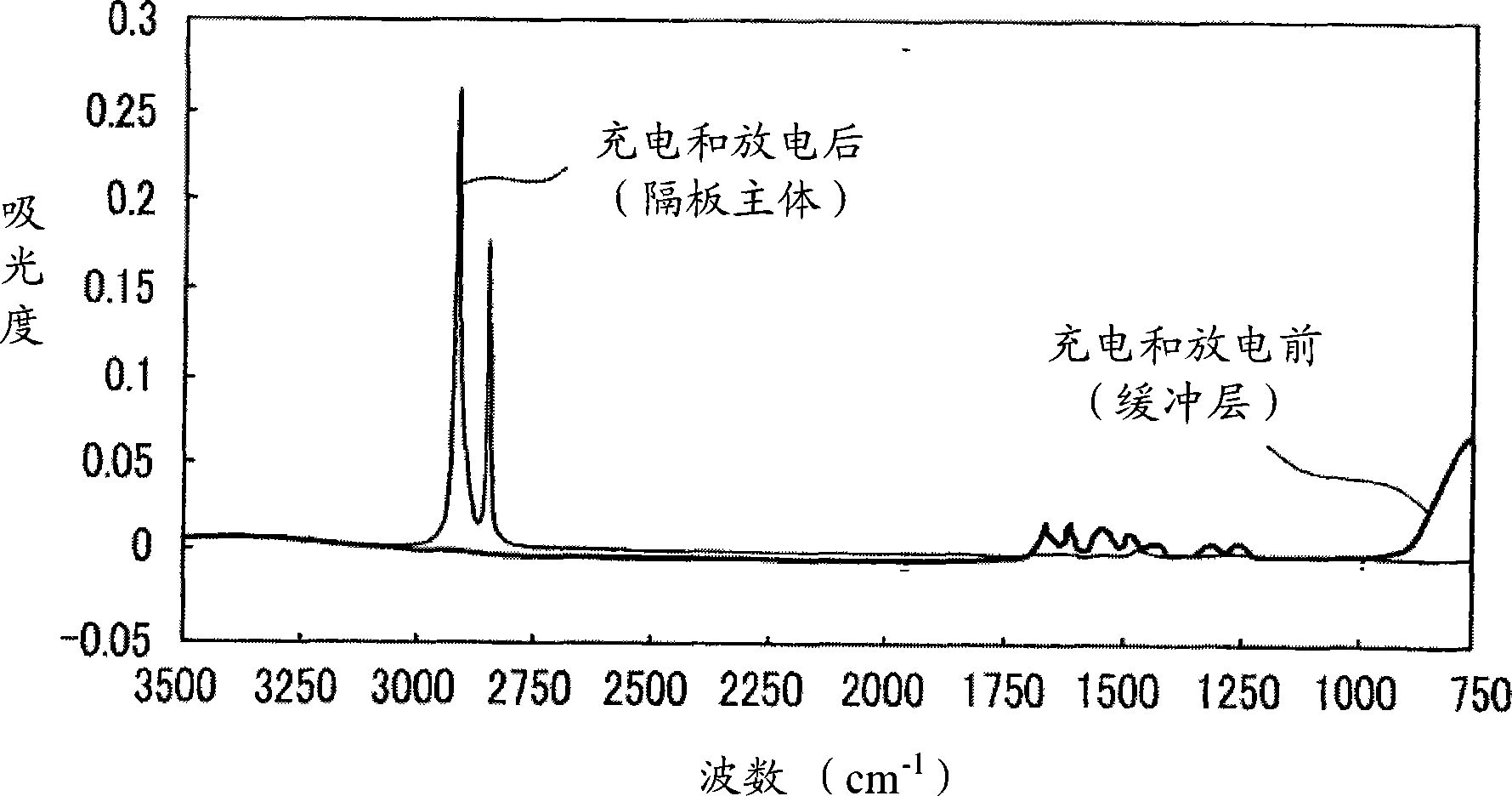

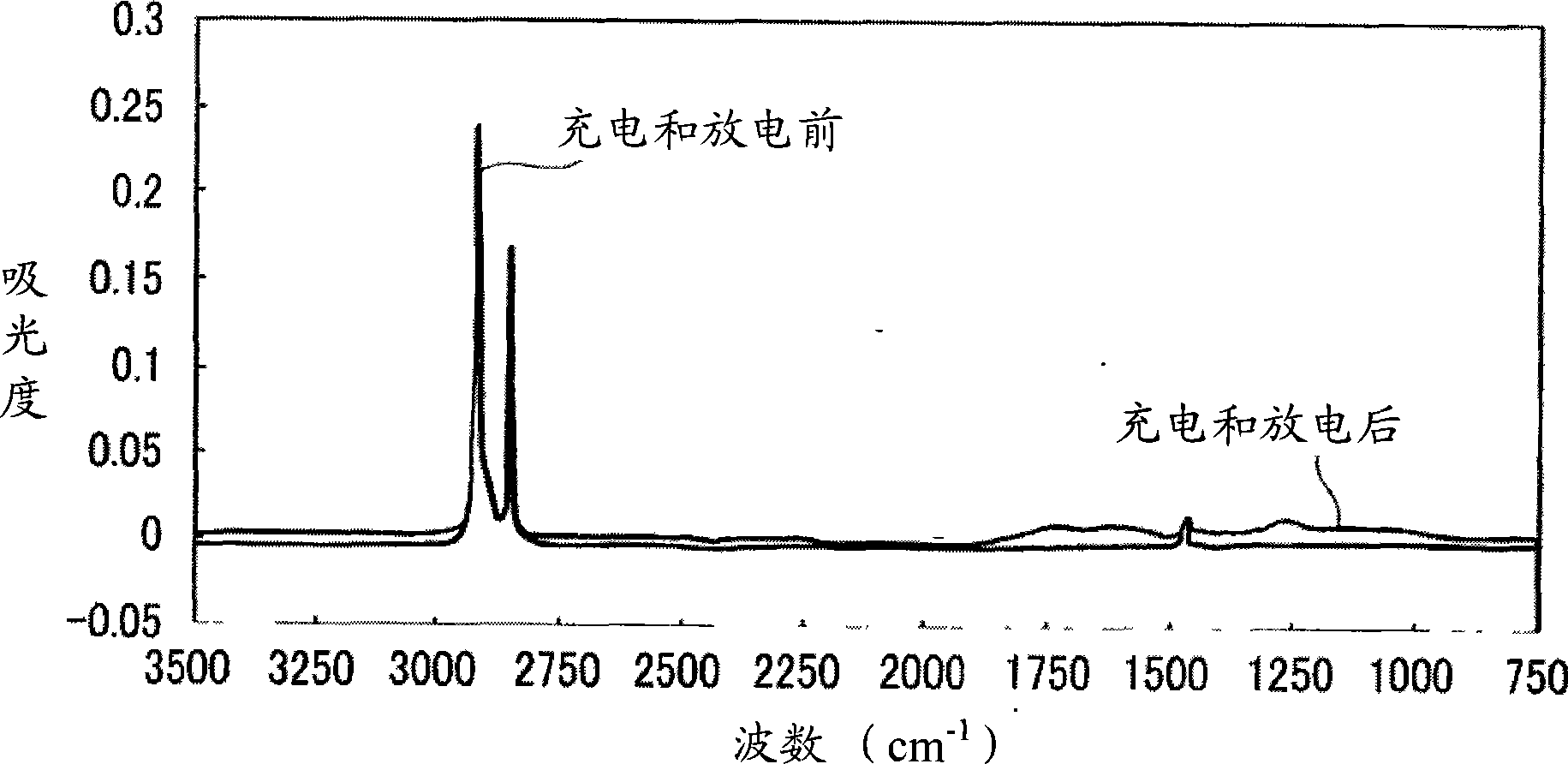

[0069] A polyethylene separator with a buffer layer of a composite including meta-aramid polymer as an organic compound and other various as shown in Table 1 (for Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com