Reactor for the production of C2 to C8 olefins from an oxygenate, water vapor, and one or more material flows containing hydrocarbon

A technology of reactors and compounds, applied in the direction of producing hydrocarbons from oxygen-containing organic compounds, chemical/physical/physicochemical nozzle reactors, carbon compound catalysts, etc., can solve problems such as non-isothermal and unsatisfactory fluid conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

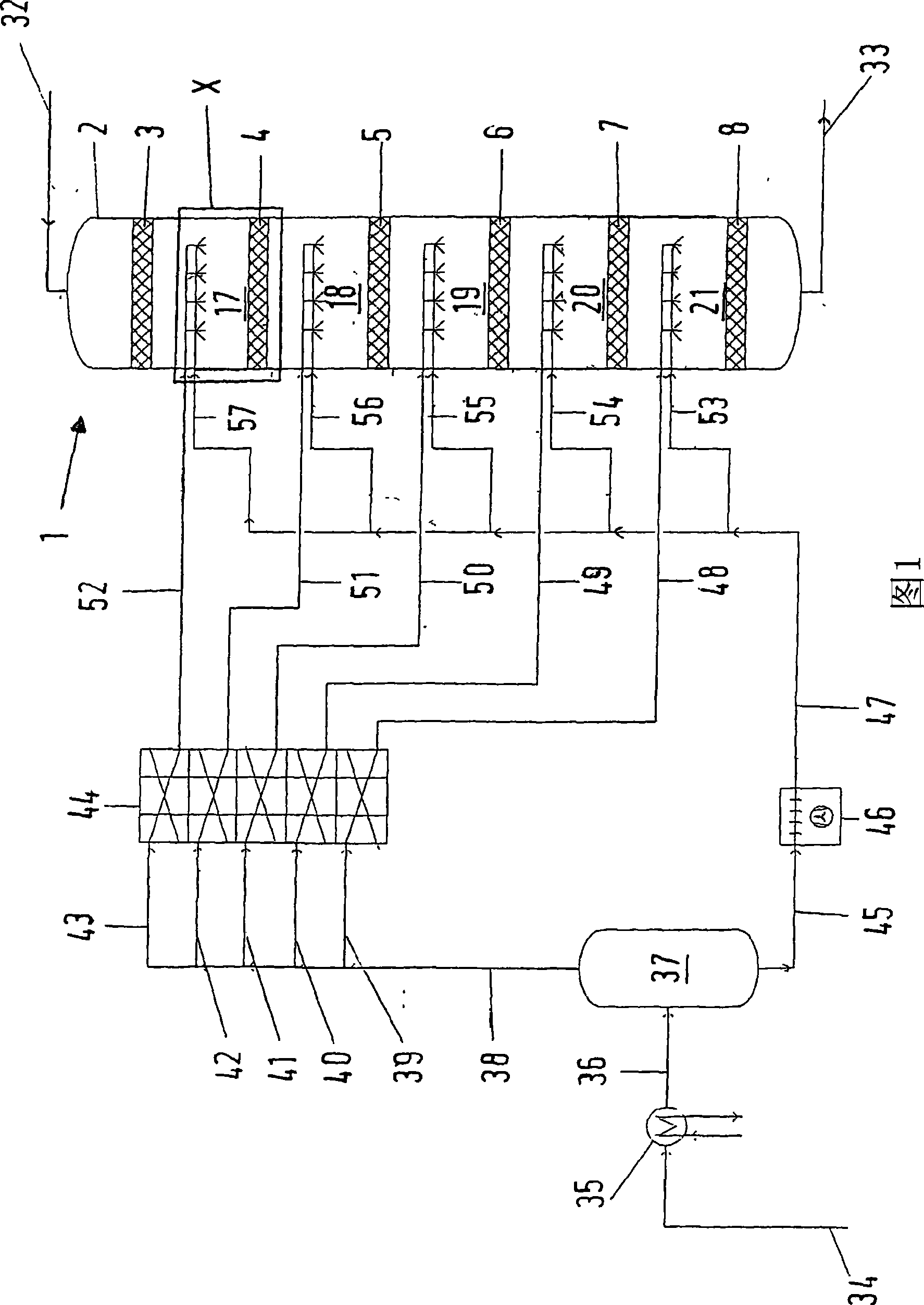

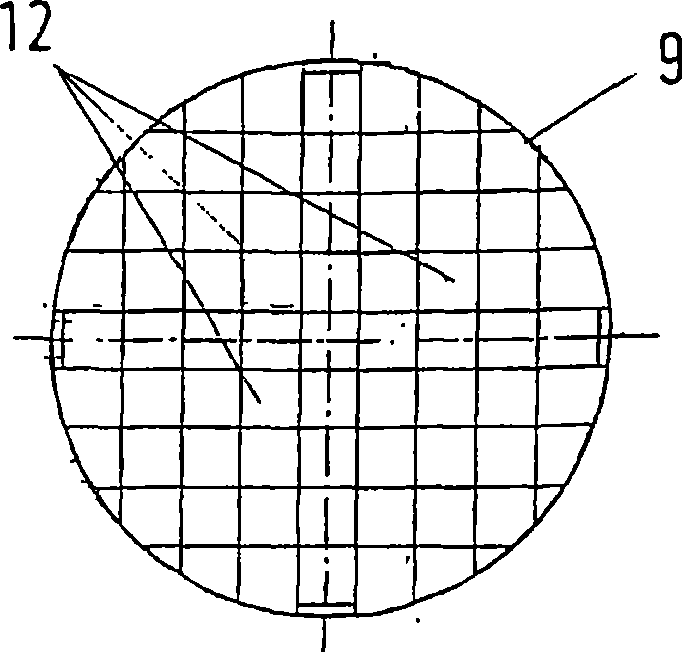

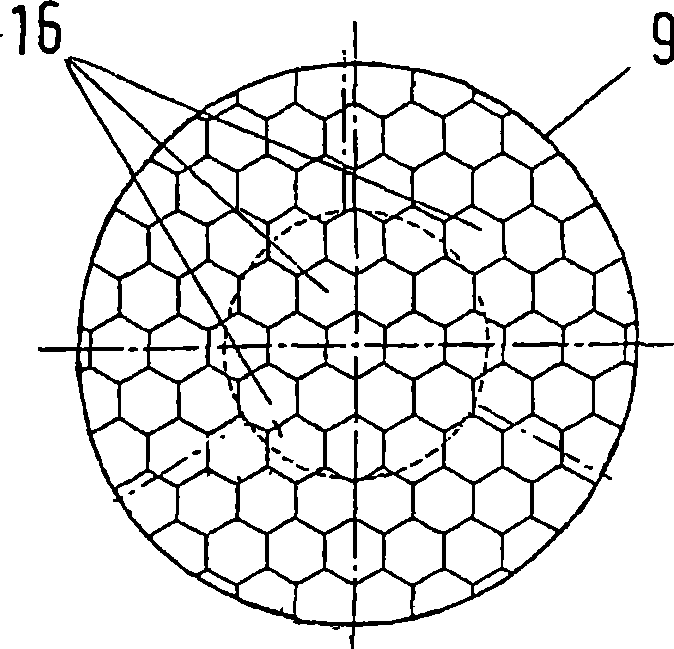

[0026] According to Figure 1, the reactor (1) consists of a vertical, cylindrical, closed vessel (2) with 6 stacked reaction stages (3, 4, 5, 6, 7, 8 ), as in Figure 2 to Figure 5 and Figure 7Depicted in part (X) of Figure 1, an unloaded tray (9) made of cubical cells (12) covered with wire mesh (10, 11) on the bottom and top surfaces, said cells ( 12) Closely connected without gaps. The lower part of the chamber (12) is filled with a 100mm layer (13) of ceramic balls having a diameter of 0.5" in the lower half layer and 0.25" in the upper half layer. A layer ( 14 ) of a granular, shape-selective zeolite catalyst of the Pentasil type is stacked on top of the layer ( 13 ) of ceramic spheres. The wire mesh (11) on the top surface is covered with a layer (15) of 100 ± 10 mm thick ceramic balls, 0.25" in diameter. Starting from the top of the vessel, a catalyst layer (14) The thickness of the layer increases steadily from one reaction stage to the downstream of the other rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com