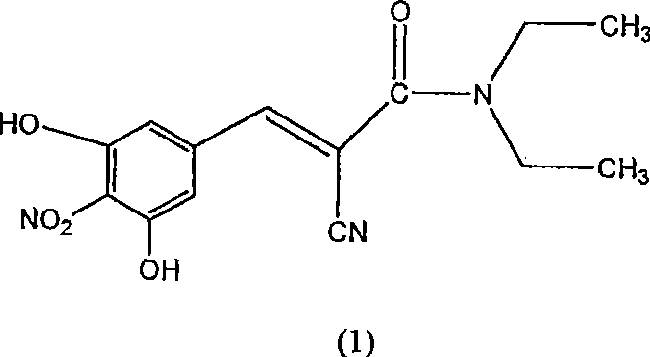

A process for the preparation of entacapone form-A

A technology of cyano group and dihydroxy group, applied in the field of A-type crystallization, can solve the problems such as the type of polytype is not disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

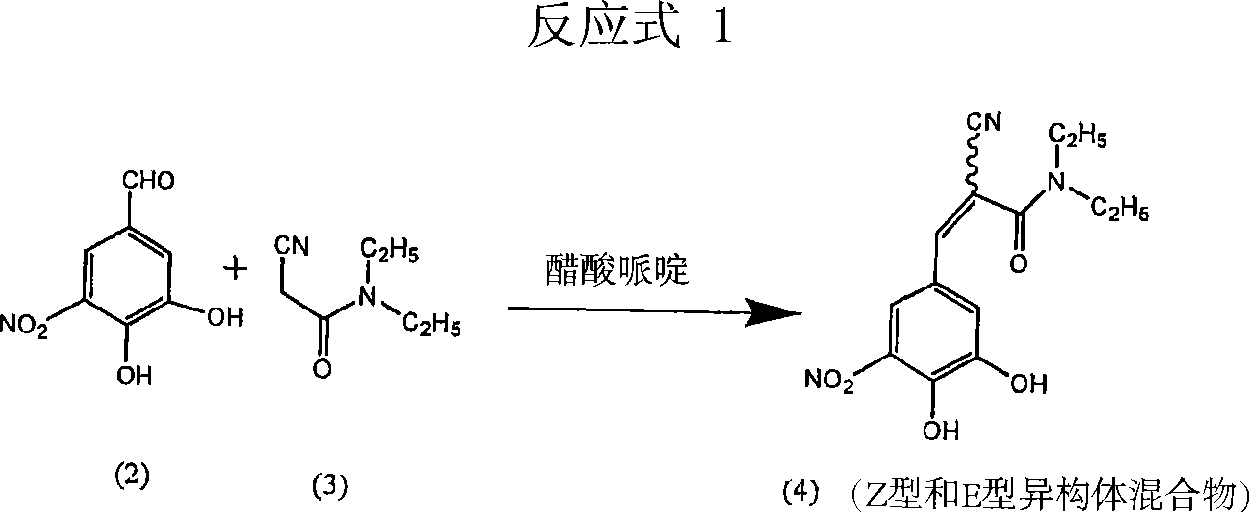

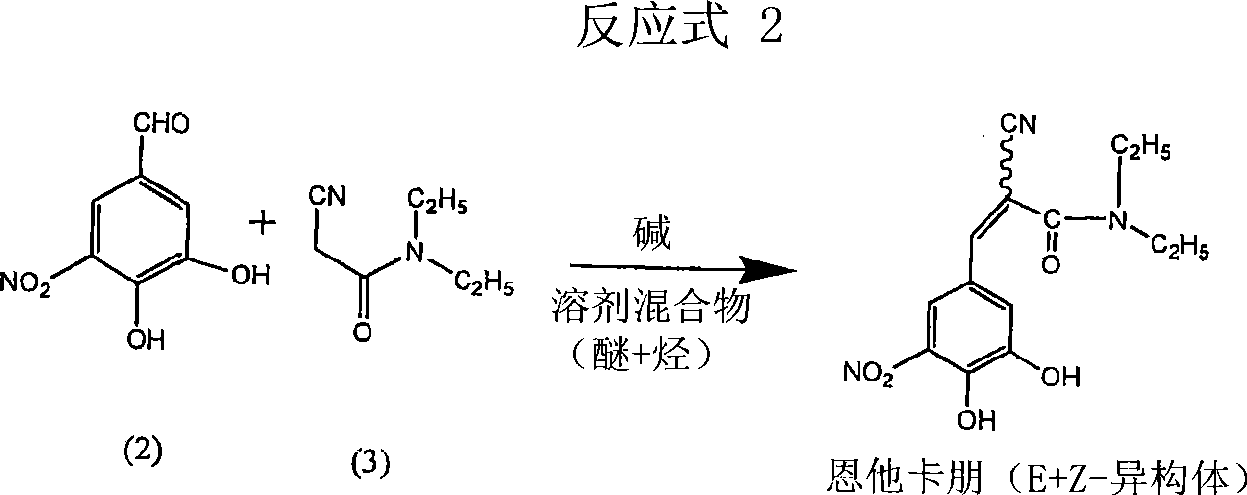

Method used

Image

Examples

Embodiment 1

[0030] Preparation of (2E)-2-cyano-3-(3,4-dihydroxy-5-nitrophenyl)-N,N-diethyl-2-acrylamide (entacapone).

[0031]3,4-dihydroxy-5-nitrobenzaldehyde (50g), N,N-diethylcyanoacetamide (76.5g), piperidine (19.2g) were loaded into a mixture containing dimethoxyethane (200ml ) and heptane (200ml) in a reaction vessel. The reaction mixture was refluxed for 15-25 hours until the disappearance of starting material (monitored by HPLC). The solvent was distilled off under high vacuum at 70-80°C. Then cool to 25-35°C. To the intermediate product in the flask was added dichloromethane (1.0 L) at 25-35°C. The mixture was stirred at this temperature for 24 hours. It was then filtered, dried and charged to a reaction flask containing methanol. The mixture was treated with activated carbon, filtered and concentrated to obtain the target compound (HPLC 99.78%, Z-isomer content <0.1%) with a yield of 75%.

Embodiment 2

[0033] 3,4-dihydroxy-5-nitrobenzaldehyde (25g), N,N-diethyl cyanoacetamide (38.25g), dibutylamine (10g) were charged into dimethoxyethane (100ml ) and heptane (100ml) in a reaction vessel. The reaction mixture was refluxed for 15-25 hours until the disappearance of starting material (monitored by HPLC). Under high vacuum at 70-80°C, the solvent was distilled off. Then cool to 25-35°C. To the intermediate product in the flask was added dichloromethane (500ml) at 25-35°C. The mixture was stirred at this temperature for 24 hours. Then, it was filtered, washed with water, dried and charged to a reaction flask containing acetonitrile. The mixture was treated with charcoal, filtered and concentrated to give the title compound (HPLC 99.7%, Z-isomer content <0.1%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com