Method for recovering etching waste liquor containing copper chloride and ferric trichloride

A technology of iron trichloride corrosion and recovery method, which is applied in the direction of chemical instruments and methods, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of low ratio, achieve risk reduction, convenient operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

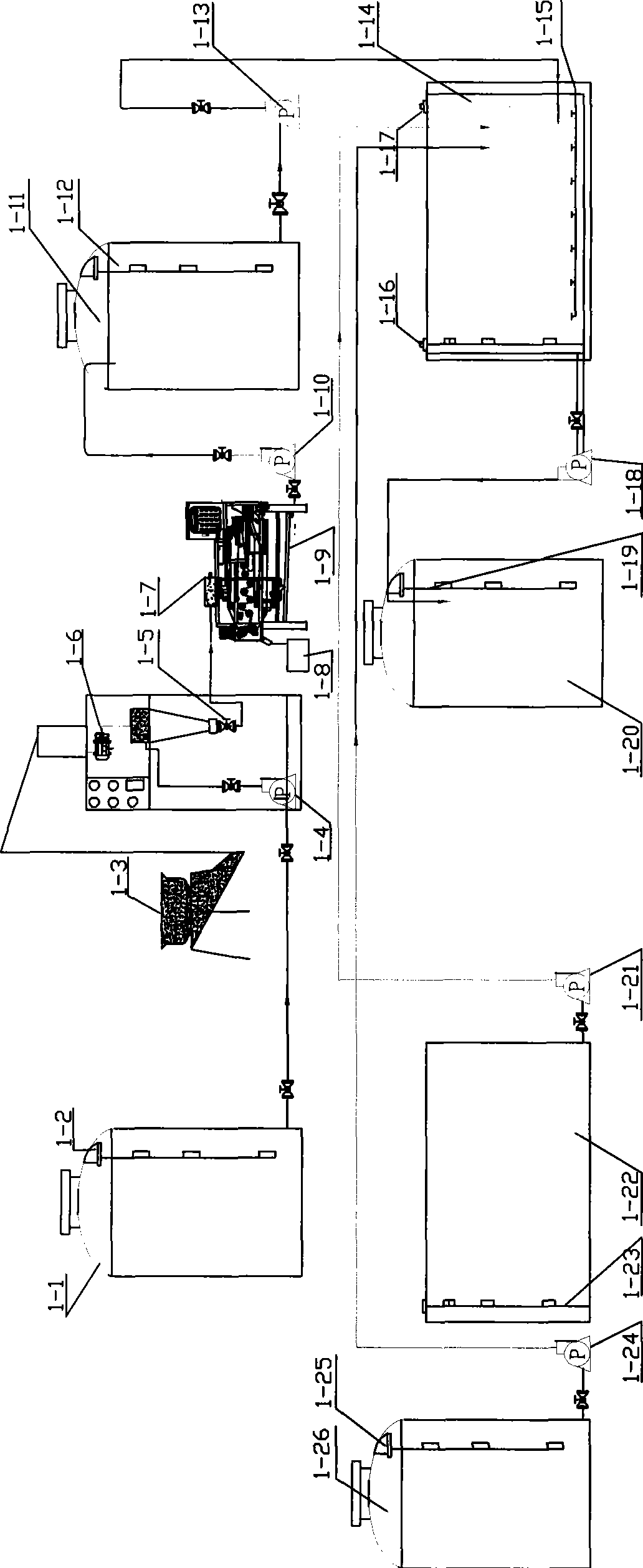

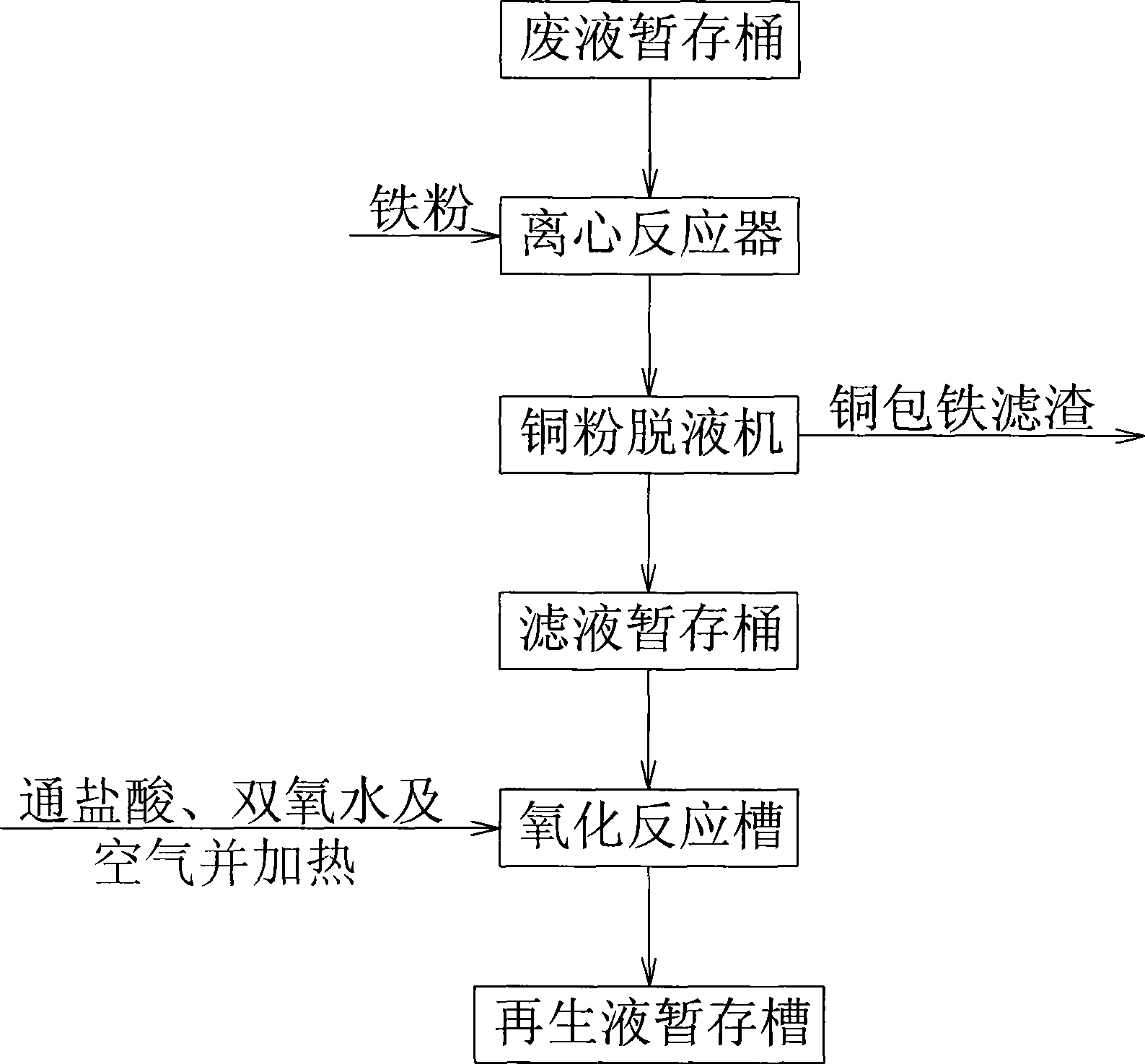

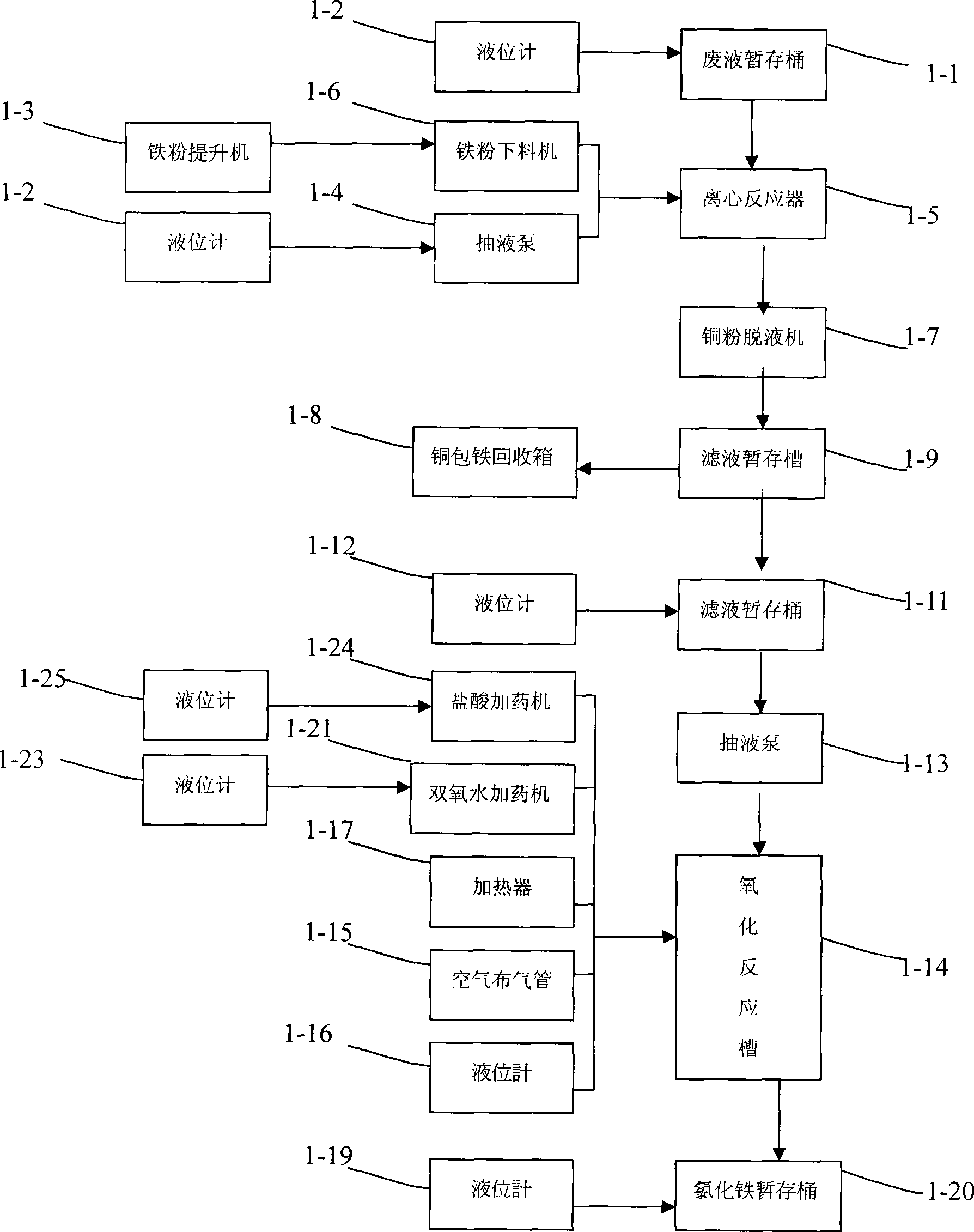

Method used

Image

Examples

Embodiment 1

[0029] Get the first etching waste liquid sample, after testing its main composition is as follows: Cu 2+ The ion concentration is 87g / L; Fe 3+ The ion concentration is 124g / L; the specific gravity of the etching waste liquid is 1.439g / cm 3 .

[0030] The first stage is the reduction stage of divalent copper ions and ferric ions.

[0031] a1. Turn on the liquid pump 1-4 (flow rate: 5L / min), pump the waste liquid in the ferric chloride waste etching liquid temporary storage barrel 1-1 into the centrifugal reactor 1-5, and the liquid level gauge 1-2 controls The amount of waste liquid in the ferric chloride waste etching liquid temporary storage barrel 1-1. When the waste liquid in the centrifugal reactor 1-5 is 50L, the Cu in the centrifugal reactor 2+ With 4350 grams, Cu 2+ Combined with 68.5mol; Fe in the centrifugal reactor 3+ With 6200 g, Fe 3+ Combined with 111mol, stop pump 1-4;

[0032] b1. The iron powder hoist 1-3 transfers the iron powder to the iron powder fe...

Embodiment 2

[0051] Get the second etching waste liquid sample, after testing its main composition is as follows: Cu 2+ The ion concentration is 94g / L; Fe 3+ The ion concentration is 118g / L; the specific gravity of the etching waste liquid is 1.422g / cm 3 .

[0052] The first stage is the reduction stage of divalent copper ions and ferric ions.

[0053] a1. Turn on the liquid pump 1-4 (flow rate: 6L / min), pump the waste liquid in the ferric chloride waste etching liquid temporary storage barrel 1-1 into the centrifugal reactor 1-5, and the liquid level gauge 1-2 controls The amount of waste liquid in the ferric chloride waste etching liquid temporary storage barrel 1-1. When the waste liquid in the centrifugal reactor 1-5 is 50L, the Cu in the centrifugal reactor 2+ With 4700 grams, Cu 2+ Combined with 74mol; Fe in the centrifugal reactor 3+ With 5900 g, Fe 3+ Combined with 105mol, stop pump 1-4;

[0054] b1. The iron powder hoist 1-3 transfers the iron powder to the iron powder fee...

Embodiment 3

[0073] Get the second etching waste liquid sample, after testing its main composition is as follows: Cu 2+ The ion concentration is 92g / L; Fe 3+ The ion concentration is 120g / L; the specific gravity of the etching waste liquid is 1.352g / cm 3 .

[0074] The first stage is the reduction stage of divalent copper ions and ferric ions.

[0075] a1. Turn on the liquid suction pump 1-4 (flow rate: 8L / min), and pump the waste liquid in the ferric chloride waste etching solution temporary storage barrel 1-1 into the centrifugal reactor 1-5, when the centrifugal reactor 1-5 When the medium waste liquid is 50L, the Cu in the centrifugal reactor 2+ With 4600 grams, Cu 2+ Combined with 72mol; Fe in the centrifugal reactor 3+ With 6000 g, Fe 3+ Combined with 107mol, stop the liquid pump 1-4 liquid pump.

[0076] b1. The iron powder hoist 1-3 transfers the iron powder to the iron powder feeder 1-6, turns on the iron powder feeder 1-6, the iron powder addition speed: 1.23kg / min, the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com