Viscosity breaking method

A technology for visbreaking and vacuum distillate oil, which is used in cracking, non-catalytic thermal cracking, petroleum industry, etc., can solve problems such as large investment and operating costs, and achieve good stability, increased yield, and reduced viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The raw material for visbreaking is atmospheric residue, that is, the density at 20°C is 0.9914g / cm 3 , the kinematic viscosity at 100°C is 304.5mm 2 / s, the residual carbon is 16.6% by weight, the freezing point is 25°C, the sulfur content is 2.51% by weight, and the asphaltene content is 10.9% by weight.

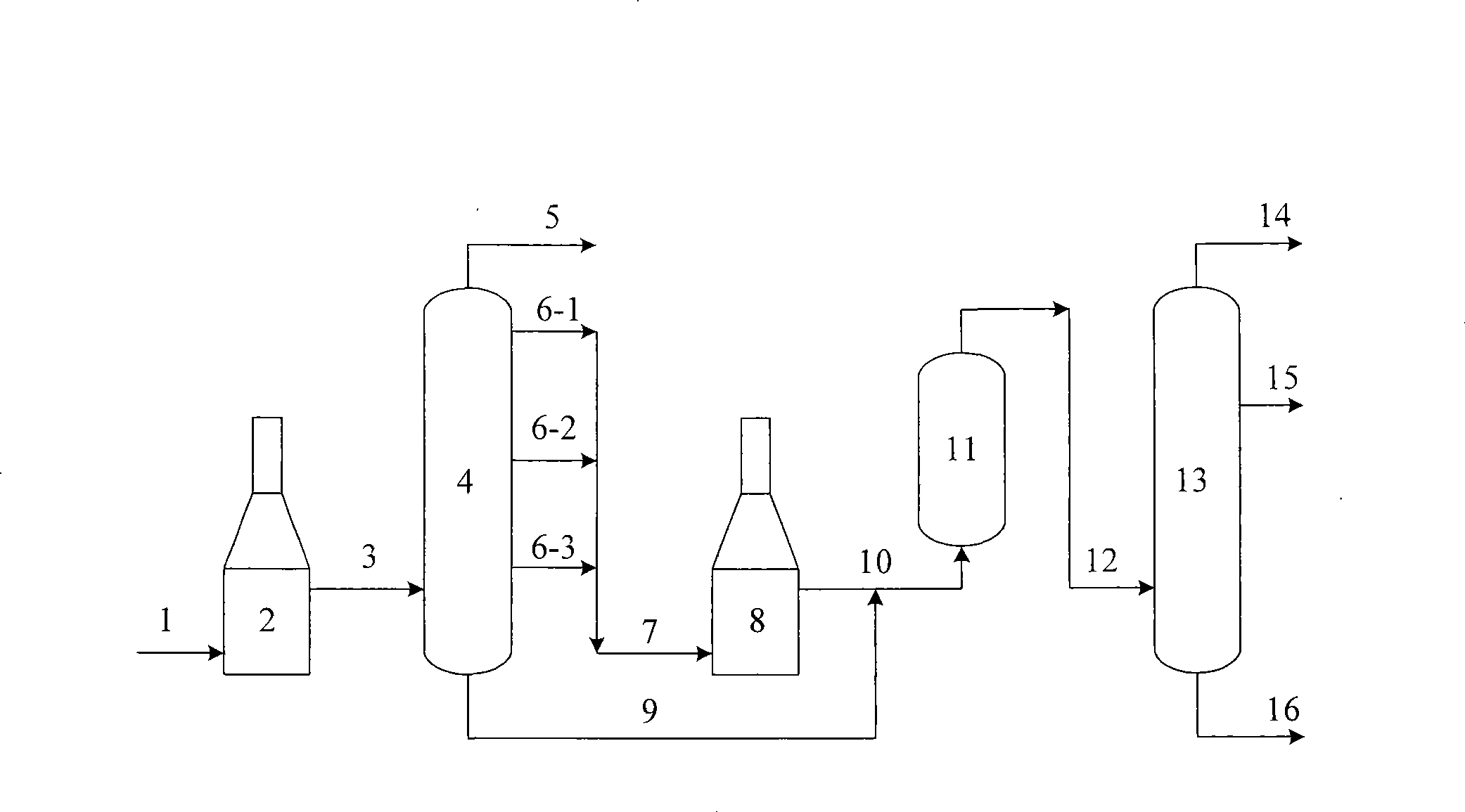

[0038] according to figure 1 The scheme shown carries out the visbreaking process of the present invention.

[0039] (1) vacuum distillation

[0040] The atmospheric residue 1 is heated to 390°C in the vacuum distillation heating furnace 2, and then enters the vacuum distillation tower 4 with a top absolute pressure of 1.8kPa through the pipeline 3 for vacuum distillation, respectively on the vacuum distillation tower, The side line 6-1, side line 6-2 and side line 6-3 in the middle and lower part distill vacuum distillate oil, and the distillation range of the mixture of the three side line distillate vacuum distillate oils is 335-598°C. The bottom of the tower...

Embodiment 2

[0055] The same atmospheric residue as in Example 1 was used as the raw material for visbreaking. according to figure 1 The scheme shown performs visbreaking.

[0056] (1) vacuum distillation

[0057] The atmospheric residue 1 is heated to 420°C in the vacuum distillation heating furnace 2, and then enters the vacuum distillation tower 4 with a top absolute pressure of 5.3kPa through the pipeline 3 for vacuum distillation, respectively on the vacuum distillation tower, The side line 6-1, side line 6-2 and side line 6-3 in the middle and lower part distill vacuum distillate oil, and the distillation range of the vacuum distillate oil mixture of the three side lines is 318-567 ° C. Vacuum residue oil above 540°C is extracted from the bottom of the pump. The vacuum distillation column top line 5 goes to the vacuum system.

[0058] (2) Visbreaking

[0059] The vacuum distillate mixture of the vacuum distillation tower side lines 6-1, 6-2 and 6-3 enters the visbreaking heating...

Embodiment 3

[0063] The same atmospheric residue as in Example 1 was used as the raw material for visbreaking. according to figure 1 The scheme shown performs visbreaking.

[0064] (1) vacuum distillation

[0065]The atmospheric residue 1 is heated to 410°C in the vacuum distillation heating furnace 2, and then enters the vacuum distillation tower 4 with a top absolute pressure of 3.0kPa through the pipeline 3 to carry out vacuum distillation, respectively on the vacuum distillation tower, The side line 6-1, side line 6-2 and side line 6-3 in the middle and lower part distill vacuum distillate oil, and the distillation range of the vacuum distillate oil mixture of the three side lines is 331-588 ° C. In the vacuum distillation tower Vacuum residue oil above 550°C is extracted from the bottom of the pump. The vacuum distillation column top line 5 goes to the vacuum system.

[0066] (2) Visbreaking

[0067] The vacuum distillate mixture of the vacuum side lines 6-1, 6-2 and 6-3 enters t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com