Ignition control apparatus and its control process

An ignition control and ignition device technology, which is applied in the field of pyrotechnics manufacturing, can solve the problems of uncontrollable detonation process of ordinary electric detonators, affecting the safety of detonators, and poor delay accuracy, so as to improve safety and reliability and reduce the risk of heavy metals. Use, delay time for precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

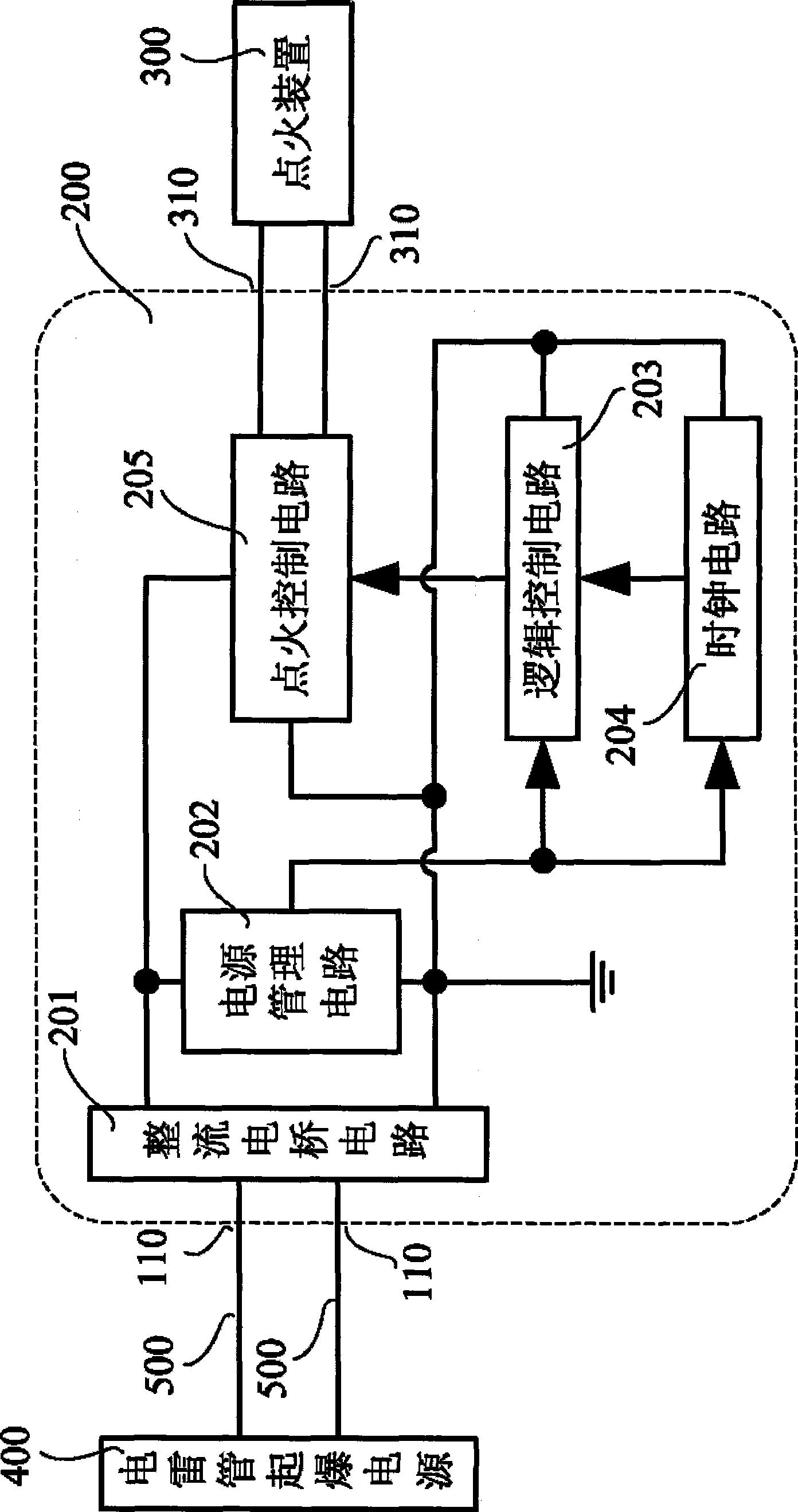

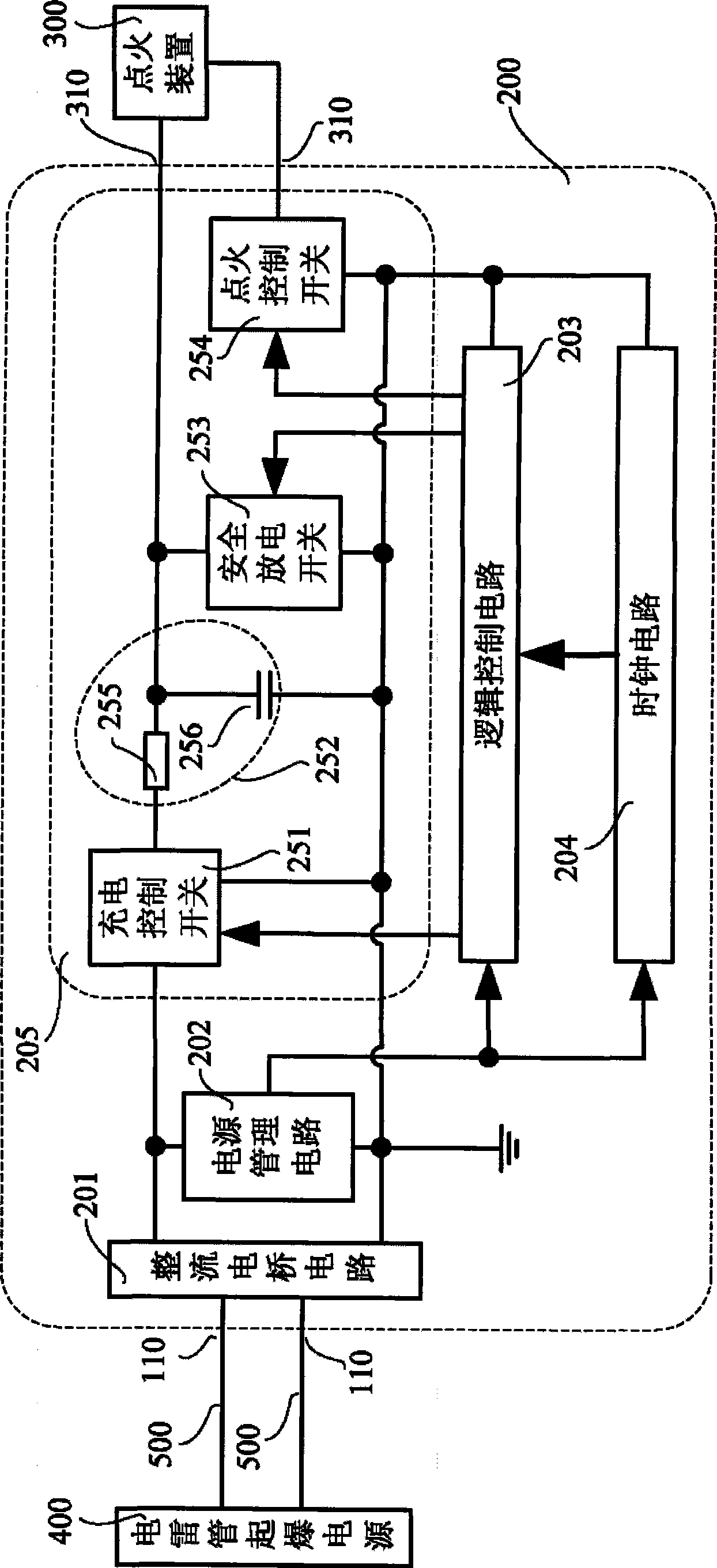

[0041]The ignition control device 200 includes a rectifier bridge circuit 201, a power management circuit 202, a logic control circuit 203, a clock circuit 204, and an ignition control circuit 205, such as figure 1 . The detailed description is as follows:

[0042] 1. One end of the rectifier bridge circuit 201 is connected to the power management circuit 202 and the ignition control circuit 205 at the same time, and one end is grounded; the other two ends lead to the outside of the ignition control device 200, and are connected to the electric detonator detonation power supply 400 outside the ignition control device 200, forming The power input terminal 110 of the ignition control device 200 . The rectifier bridge circuit 201 is used to convert the polarity of the energy input through the power input term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com