Control method for common roll grinding machine

A technology of roll grinding machine and control method, which is applied in the direction of general control system, digital control, program control, etc., can solve the problems of laborious operation and inaccurate feeding, and achieve the goal of simplifying the mechanical transmission device, reducing labor intensity, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

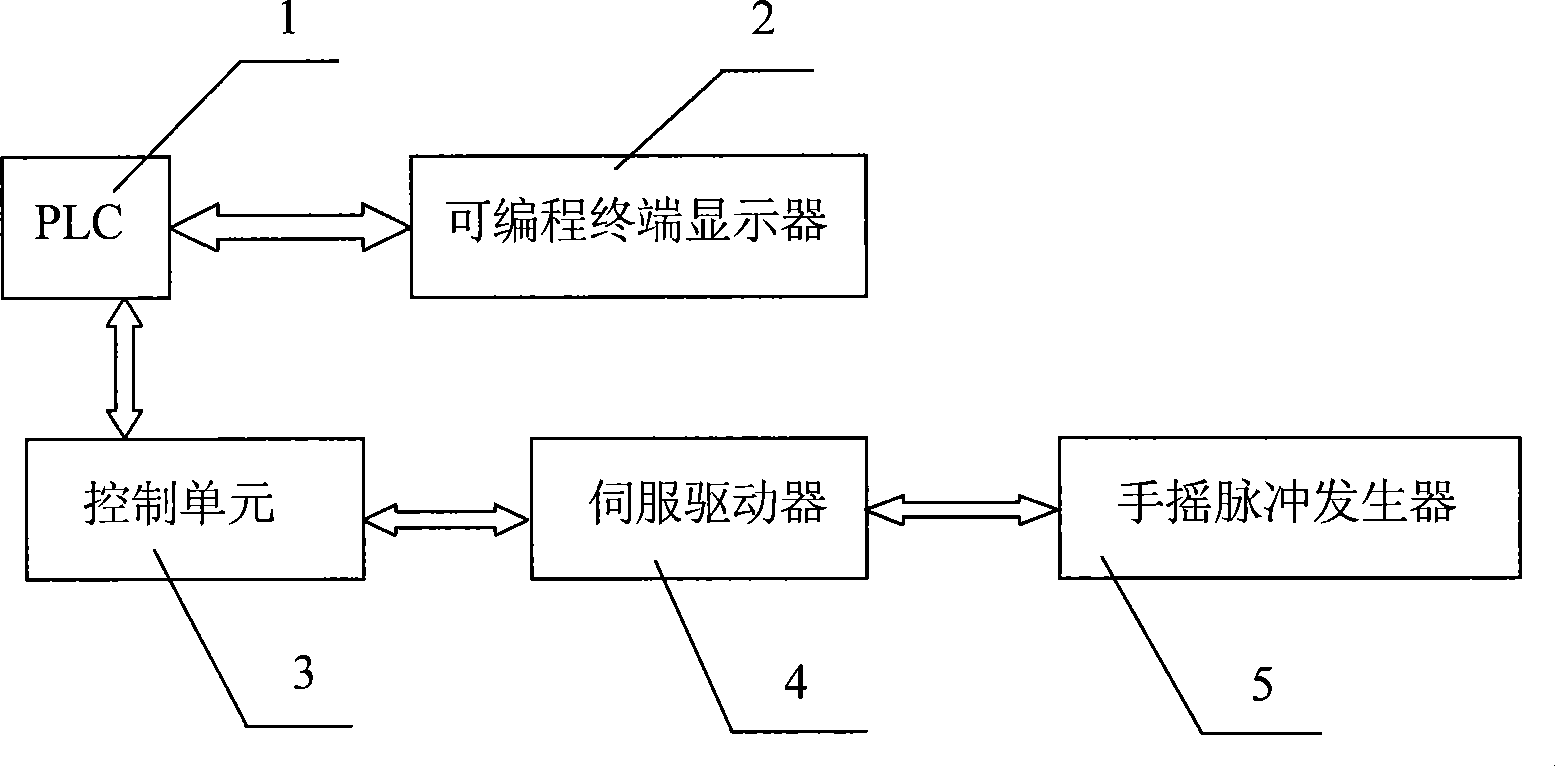

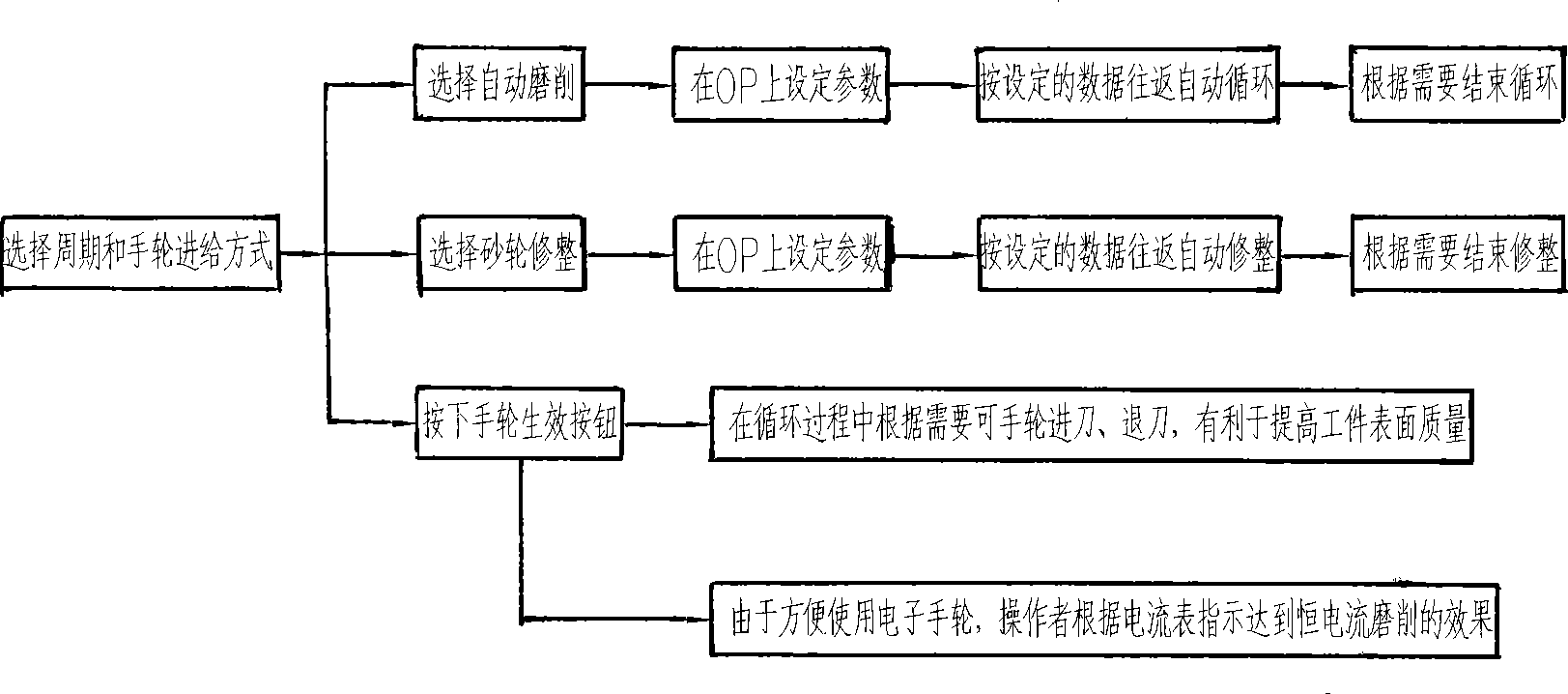

[0020] Example 1, see figure 1 , 2 , the control method of a common roll grinder includes a PLC programmable controller 1, the PLC programmable controller 1 is connected to the programmable terminal display 2 through the PROFBUS data bus, and its feature also includes the described PLC programmable controller. The controller 1 is connected to the control unit 3 through the data bus, and the control unit 3 is connected to the servo driver 4 and the manual pulse generator 5 through the data bus; the steps of the roll grinder control include:

[0021] (1) Input the grinding length and cycle feed on the programmable terminal display OP;

[0022] (2) During the grinding process, manually modify the periodic feed rate on the OP as needed;

[0023] (3) During the grinding process, select the cycle and handwheel feed mode. The selection knob is installed on the machine operation panel, and the manual pulse generator is used to participate in the feed according to the grinding requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com