Production method of touch screen

一种触摸屏、屏蔽层的技术,应用在纳米结构制造、数据处理的输入/输出过程、仪器等方向,能够解决机械和化学耐用性不好、电阻阻值分布不均匀、无法用柔性显示设备等问题,达到优异力学特性、成本低、降低制作成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

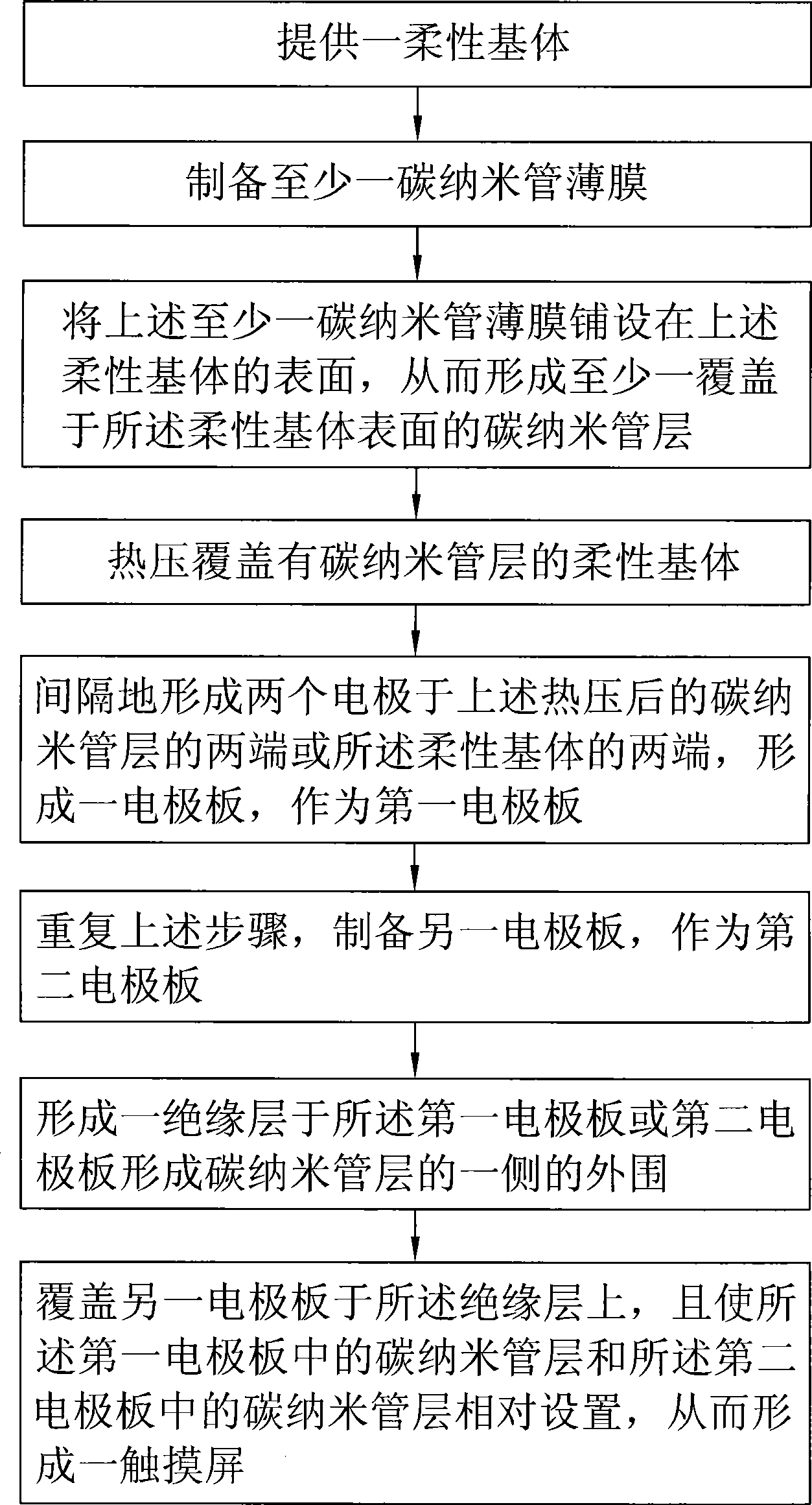

[0014] see figure 1 , the embodiment of the technical solution provides a method for manufacturing a touch screen, which mainly includes the following steps:

[0015] Step 1: providing a flexible substrate.

[0016] The flexible substrate is a flexible planar structure with a thickness of 0.01 millimeter to 1 centimeter. The flexible base is formed of flexible materials such as plastic and resin. Specifically, the material of the flexible substrate can be polyester materials such as polycarbonate (PC), polymethylmethacrylate (PMMA), polyethylene terephthalate (PET), and polyethersulfone ( PES), polyimide (PI), cellulose ester, benzocyclobutene (BCB), polyvinyl chloride (PVC) and acrylic resin and other materials. It can be understood that the material forming the flexible base is not limited to the materials listed above, as long as the flexible base has certain flexibility and good transparency.

[0017] In the embodiment of the technical solution, the flexible substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com