Positive temperature coefficient material and thermistor containing the material and preparation method therefore

A technology of positive temperature coefficient and content, applied in the field of thermistors and their preparation, can solve the problems of poor stability of PTC strength at room temperature, and achieve good stability, good room temperature resistance stability, and good PTC strength stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

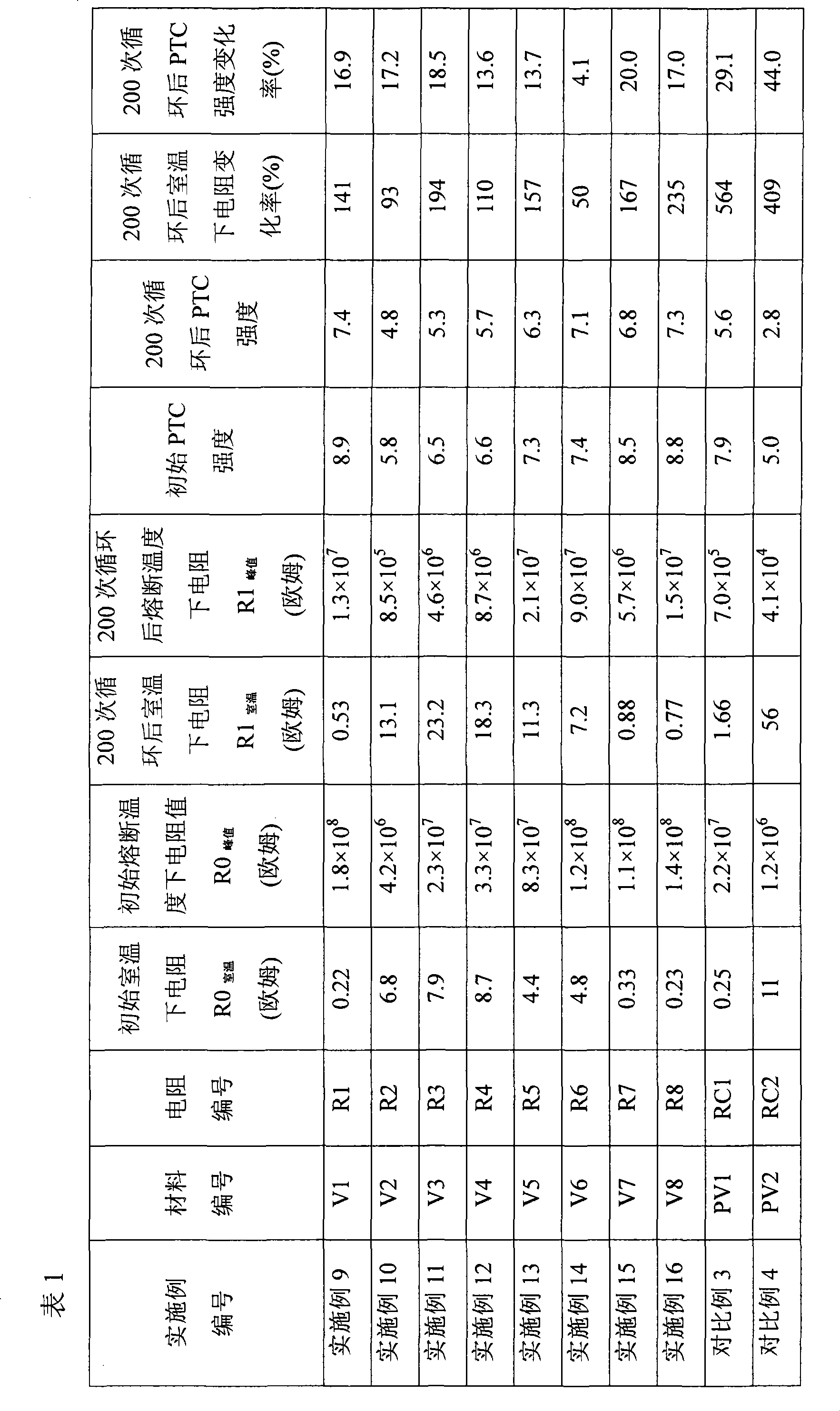

Examples

preparation example Construction

[0027] The preparation method of the thermistor provided by the present invention includes heating and melting the mixture containing resin, conductive filler, non-conductive filler, auxiliary agent, crosslinking agent and additive, and then extruding the obtained melt into granules, wherein the additive One or more selected from silicon dichloride, sodium fluoride and carbon tetrachloride.

[0028] According to the method of the present invention, based on the total weight of the mixture, the amount of each substance is such that the content of the resin in the mixture is 10-60% by weight, preferably 10-50% by weight; the content of the conductive filler is 30-80% by weight %, preferably 35-75% by weight; the content of non-conductive filler is 1-15% by weight, preferably 1-10% by weight; the content of auxiliary agent is 1-10% by weight, preferably 1-8% by weight; The total content of linking agent and additive is 1-10% by weight, preferably 1-8% by weight; wherein, the weig...

Embodiment 1

[0044] This embodiment is used to illustrate the preparation of the positive temperature coefficient material and thermistor of the present invention.

[0045] 14 parts by weight of high-density polyethylene (density 0.950 g / cm 3 , melting point 132°C, weight average molecular weight 200,000), 75 parts by weight of nickel powder, 5 parts by weight of silicon dioxide, 2 parts by weight of antioxidant 1010, 2 parts by weight of KT114 type titanate coupling agent and 1 part by weight of crosslinking agent The agent tetraethylene glycol dimethacrylate and 1 part by weight of the additive silicon dichloride are added to the high mixer, mixed at room temperature (25 ° C), first stirred at 800 rpm for 10 minutes, and then in the Stir at 2000 rpm for 3 minutes to obtain a mixture.

[0046] The mixture obtained above was sent into a twin-screw compounding extruder (SJSH-30 type, Nanjing Rubber and Plastic Machinery Factory), the length-to-diameter ratio of the extruder was L:D=36:1, a...

Embodiment 2

[0050] This embodiment is used to illustrate the preparation of the positive temperature coefficient material and thermistor of the present invention.

[0051] 25 parts by weight of high-density polyethylene (density 0.950 g / cm 3 , melting point 132°C, weight average molecular weight 200,000), 50 parts by weight of nickel powder and 10 parts by weight of carbon black, 6 parts by weight of magnesium oxide, 2 parts by weight of antioxidant 1010, 1 part by weight of KT114 type titanate coupling agent and Add 2 parts by weight of the crosslinking agent tetraethylene glycol dimethacrylate and 4 parts by weight of the additive sodium fluoride into the high mixer, mix at room temperature (25°C), and first stir at 800 rpm for 10 minutes , and then stirred at a speed of 2000 rpm for 5 minutes to obtain a mixture.

[0052] The mixture obtained above was fed into a twin-screw compounding extruder (SJSH-30 type, Nanjing Rubber and Plastic Machinery Factory), and the mixture was melt-extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com