Method and apparatus for diagnosing and correcting basal lamina offset

A correction method and technology of a correction device, applied in the field of microelectronics, can solve the problems of high implementation cost, microprocessing chips and electronic components are not suitable for high temperature and vacuum environment, a large number of complex image processing algorithms, etc. Sheet damage and production loss, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

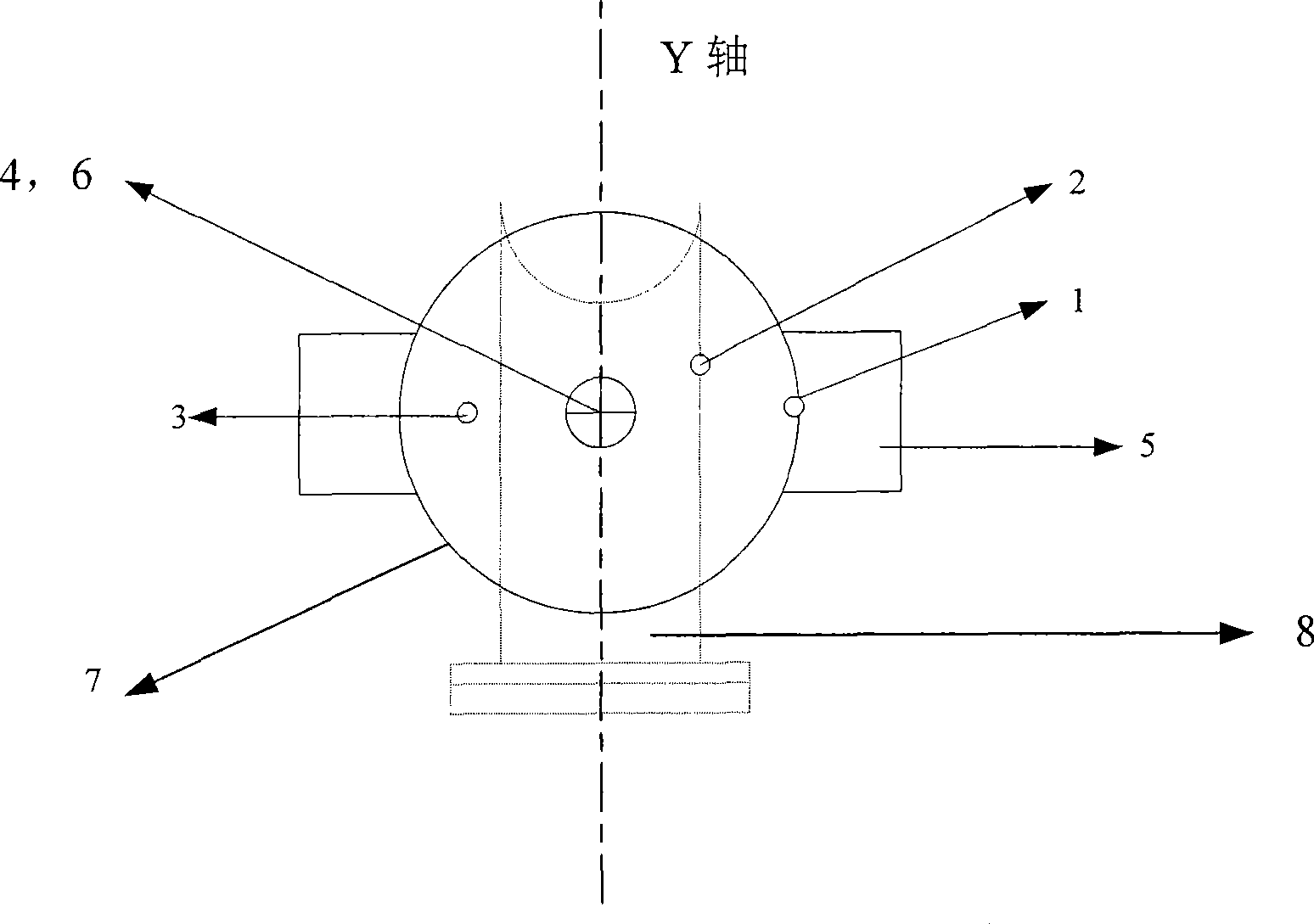

[0035] Such as figure 1 As shown, the substrate offset diagnosis and correction device of the present invention includes a diagnosis unit and a correction unit.

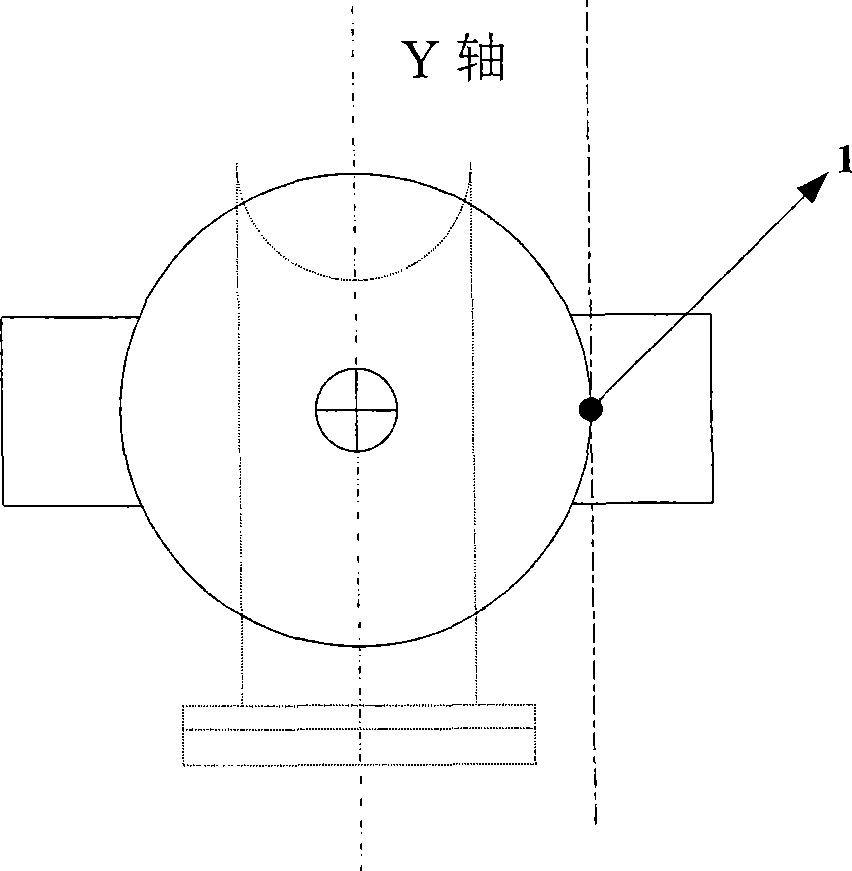

[0036] Such as figure 1 , 2 As shown, the diagnostic unit includes a first sensor 1, and the first sensor 1 is placed on the tangent line of the outer circumference of the substrate when the center 6 of the substrate coincides with the center 4 of the manipulator finger, wherein the tangent line is a tangent line parallel to the Y axis. In this embodiment, the first sensor 1 adopts a photoelectric sensor, including a light emitting device and a light receiving device, and the light emitting device and the light receiving device are respectively arranged above and above the plane where the substrate is located at a distance from the tangent position. below.

[0037] In fact, the above diagnostic unit alone can constitute a substrate offset diagnostic device.

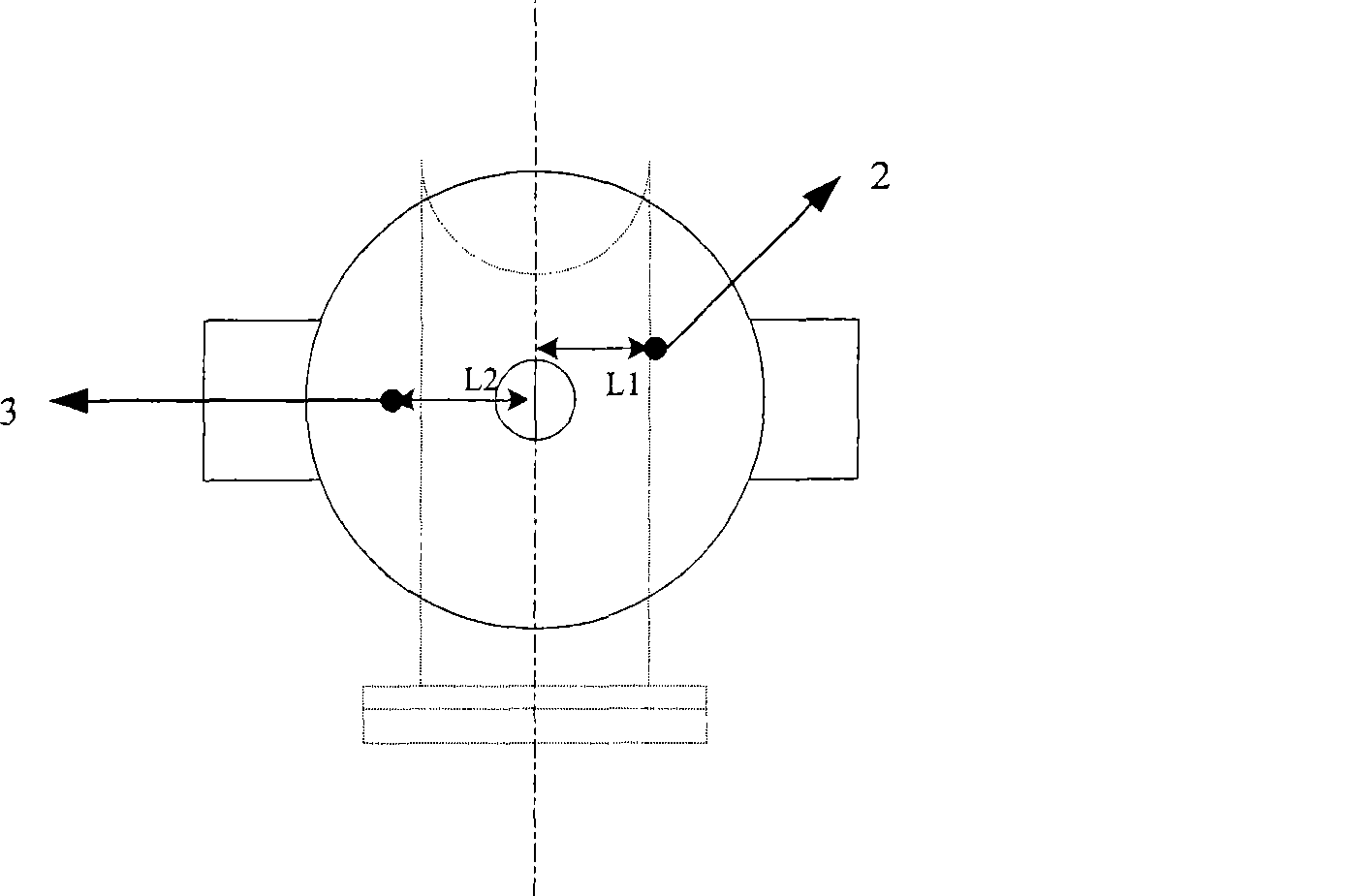

[0038] Such as figure 1 , 3 As shown, the calibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com