Method and device for producing optical fiber

A manufacturing method and optical fiber technology, applied in the direction of manufacturing tools, glass manufacturing equipment, fiber mechanical structure, etc., can solve the problem of not being able to control the thickness of the coating layer separately, and achieve the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

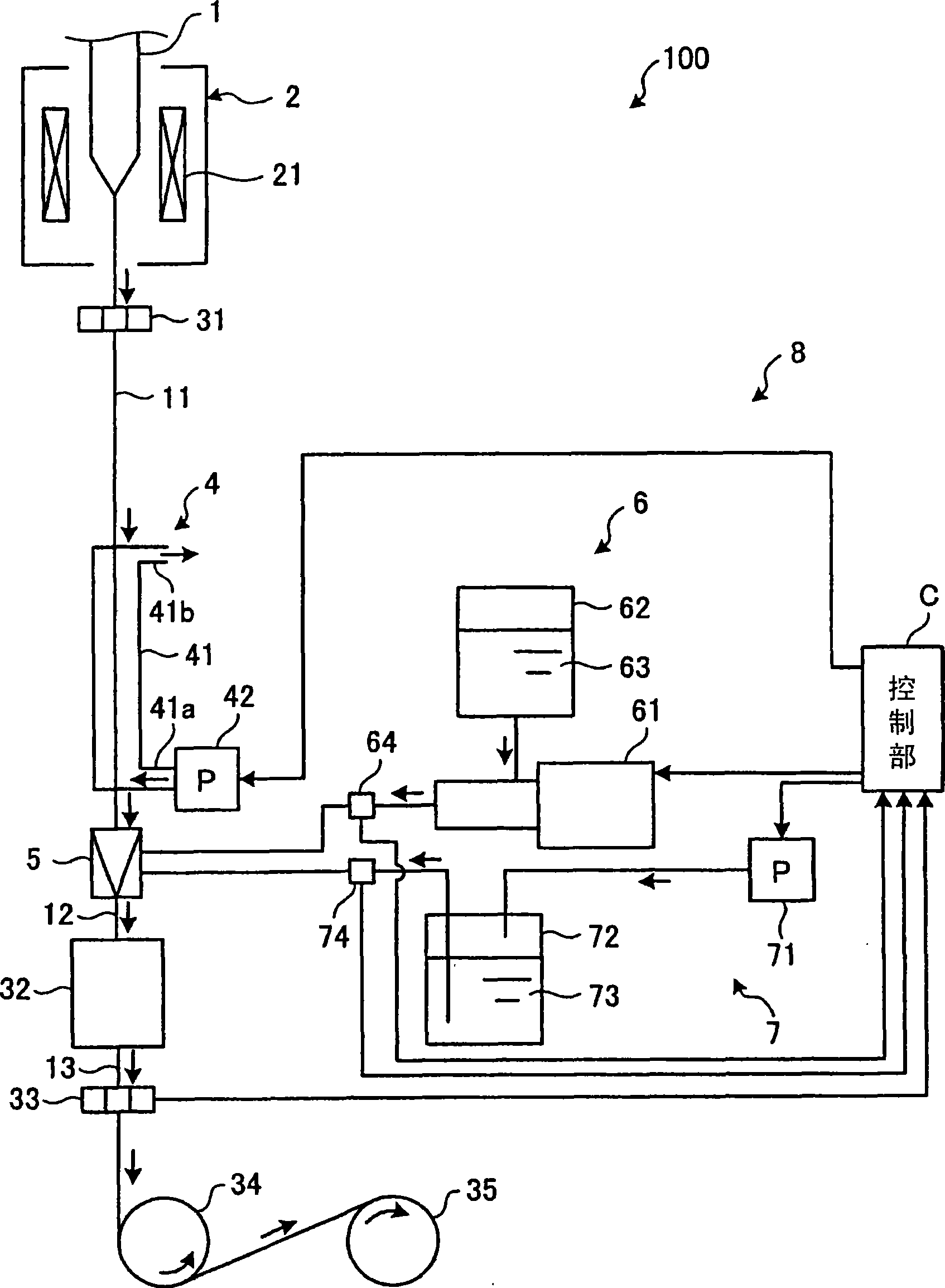

[0073] figure 1 It is a block diagram schematically showing the optical fiber manufacturing apparatus according to Embodiment 1 of the present invention. Such as figure 1 As shown, this manufacturing apparatus 100 has a wire drawing furnace 2, a temperature adjustment device 4, a resin coating device 8, and an ultraviolet irradiation device 32 as a coating layer forming device, and also includes laser outer diameter measuring devices 31, 32, guide rollers 34, and a winder 35 .

[0074] First, a method of manufacturing an optical fiber using the manufacturing apparatus 100 will be schematically described. In this manufacturing device 100, the drawing furnace 2 melts the front end portion of the optical fiber preform 1 by the heater 21 to draw the optical fiber 11, and then measures the outer diameter of the drawn optical fiber 11 by the laser outer diameter measuring device 31, and the temperature is adjusted. The device 4 cools the optical fiber 11 to a prescribed temperatu...

Embodiment 1

[0099] use as figure 1 The manufacturing apparatus shown manufactures an optical fiber according to the first embodiment. At this time, the linear speed of drawing is set to 2000 m / min, so that the outer diameter of the drawn optical fiber reaches 0.125 mm.

[0100] In addition, the number of revolutions of the quantitative pump is controlled so that the detection value of the pressure sensor reaches 1.2Mpa. At this time, the following control is carried out. When the outer diameter of the inner coating layer calculated according to the ejection amount is smaller than the target value of 0.19 mm, the flow rate of He gas in the temperature adjustment device is increased to reduce the temperature of the optical fiber, so that the rotation of the quantitative pump is reduced. When the number increases, when the situation is opposite, reduce the flow rate of He gas to increase the temperature of the optical fiber, so that the number of rotations of the quantitative pump is reduce...

Embodiment approach 2

[0107] Embodiment 2 of the present invention will be described below. In the optical fiber manufacturing method according to the second embodiment, in the same manufacturing apparatus 100 as in the first embodiment, the resin supply device 7 using a pressure pump is replaced with the same resin supply device as the resin supply device 6 using a quantitative pump. , to manufacture optical fibers with such a manufacturing device.

[0108] In the second embodiment, in the above-mentioned replaced resin supply device, the rotation speed of the metering pump is controlled in accordance with the outer diameter measured by the laser outer diameter measuring device 33 . According to Embodiment 2, as in Embodiment 1, even if the drawing speed of the optical fiber is high, the thickness of the inner coating layer, which cannot be directly measured, can be stabilized at a desired value in the longitudinal direction. The thickness of each layer of the two coating layers is stabilized at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com