Processing method for organotin wastewater containing high concentration chloride

A treatment method, organotin technology, applied in the direction of oxidized water/sewage treatment, etc., can solve problems such as separation and difficult cleaning of fiber balls, achieve the effect of increasing oxygen pressure and oxidation speed, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

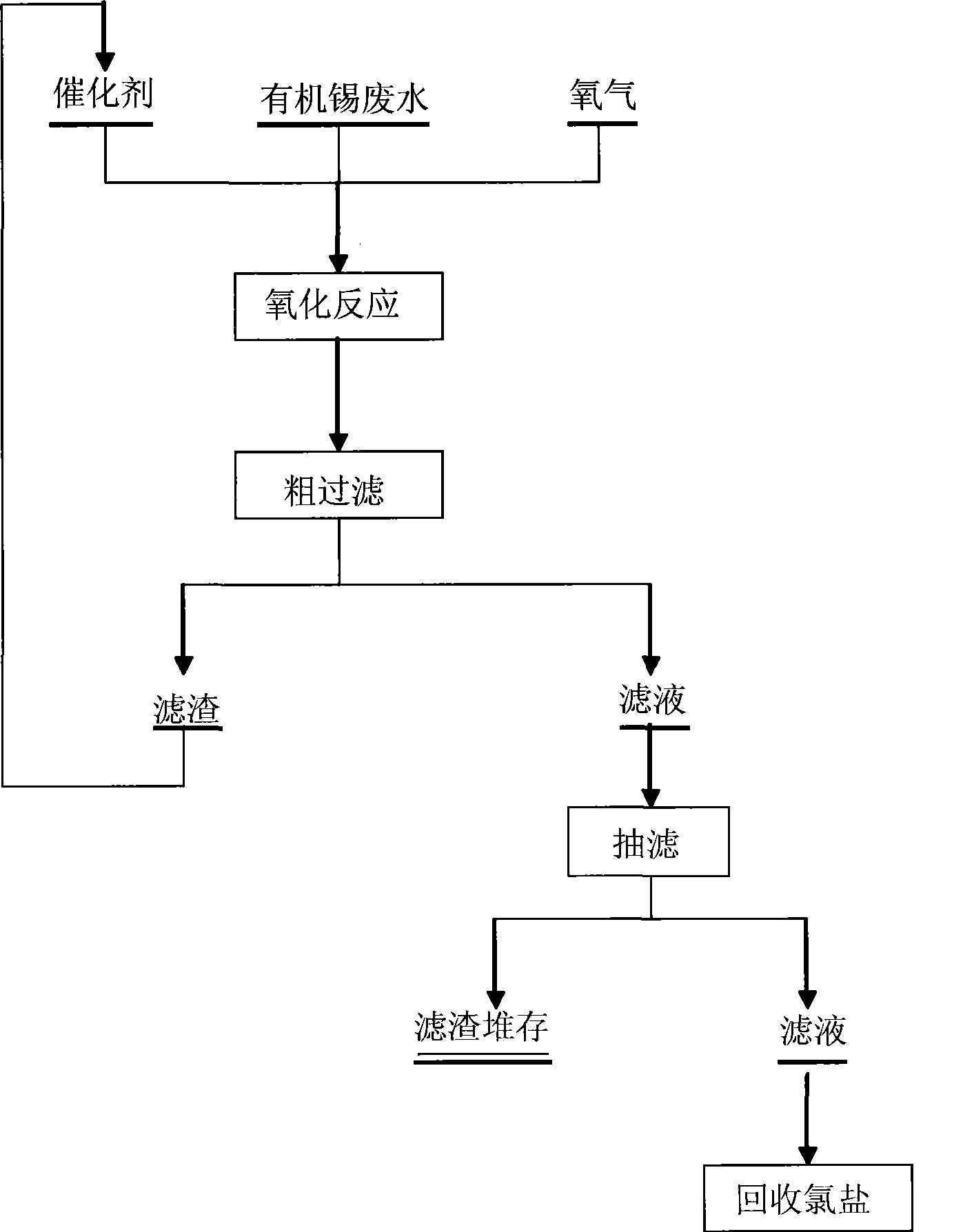

Image

Examples

Embodiment 1

[0014] Example 1: Take 3L organic tin wastewater with an organic matter content of 2812mg / L, put it into an autoclave, add 30g of catalyst, start stirring, start heating, when the temperature reaches 90°C, start to pass oxygen, and at a temperature of 200°C, the reaction 90min. After the reaction is over, close the oxygen inlet valve, turn off the heating, release the pressure and discharge the material. The feed liquid is initially filtered with a 100-mesh stainless steel screen, and the initial filter residue is returned to use. The filtrate is vacuum filtered and the suction filter residue is stored. The content of organic matter in the filtrate is 10.69 mg / L, and the removal rate of organic matter is calculated to be 99.62%, and the chlorine salt in suction filtration is recovered.

Embodiment 2

[0015] Example 2: Take 3L of organotin waste water with an organic content of 996mg / L, put it into an autoclave, add 20g of the catalyst recovered in Example 1, start stirring, start heating, when the temperature reaches 90°C, start to pass oxygen, at a temperature of 150°C ℃, react for 60min. After the reaction is over, close the oxygen inlet valve, turn off the heating, release the pressure and discharge the material. The feed liquid is initially filtered with a 100-mesh stainless steel screen, and the initial filter residue is returned to use. The filtrate is vacuum filtered and the suction filter residue is stored. The content of organic matter in the filtrate is 8.86 mg / L, and the removal rate of organic matter is calculated to be 99.11%, and the chlorine salt in suction filtration is recovered.

Embodiment 3

[0016] Example 3: Take 3L of organotin wastewater with an organic matter content of 227mg / L, put it into an autoclave, add 10g of the catalyst recovered in Example 2, start stirring, start heating, when the temperature reaches 30°C, start to pass oxygen, at a temperature of 100°C °C for 1 hour. After the reaction is over, close the oxygen inlet valve, turn off the heating, release the pressure and discharge the material. The feed liquid is initially filtered with a 100-mesh stainless steel screen, and the initial filter residue is returned to use. The filtrate is vacuum filtered and the suction filter residue is stored. The content of organic matter in the suction filtrate is 2.19 mg / L, and the removal rate of organic matter is calculated to be 99.04%, and the chlorine salt in the suction filtration is recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com