Optical sensor for high-flux dust particle counter

A particle counter and optical sensor technology, applied in the field of optical sensors, can solve problems such as low light energy conversion efficiency, difficult system adjustment, unfavorable signal-to-noise ratio, etc., and achieve the effects of reducing transmission loss, improving signal-to-noise ratio, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

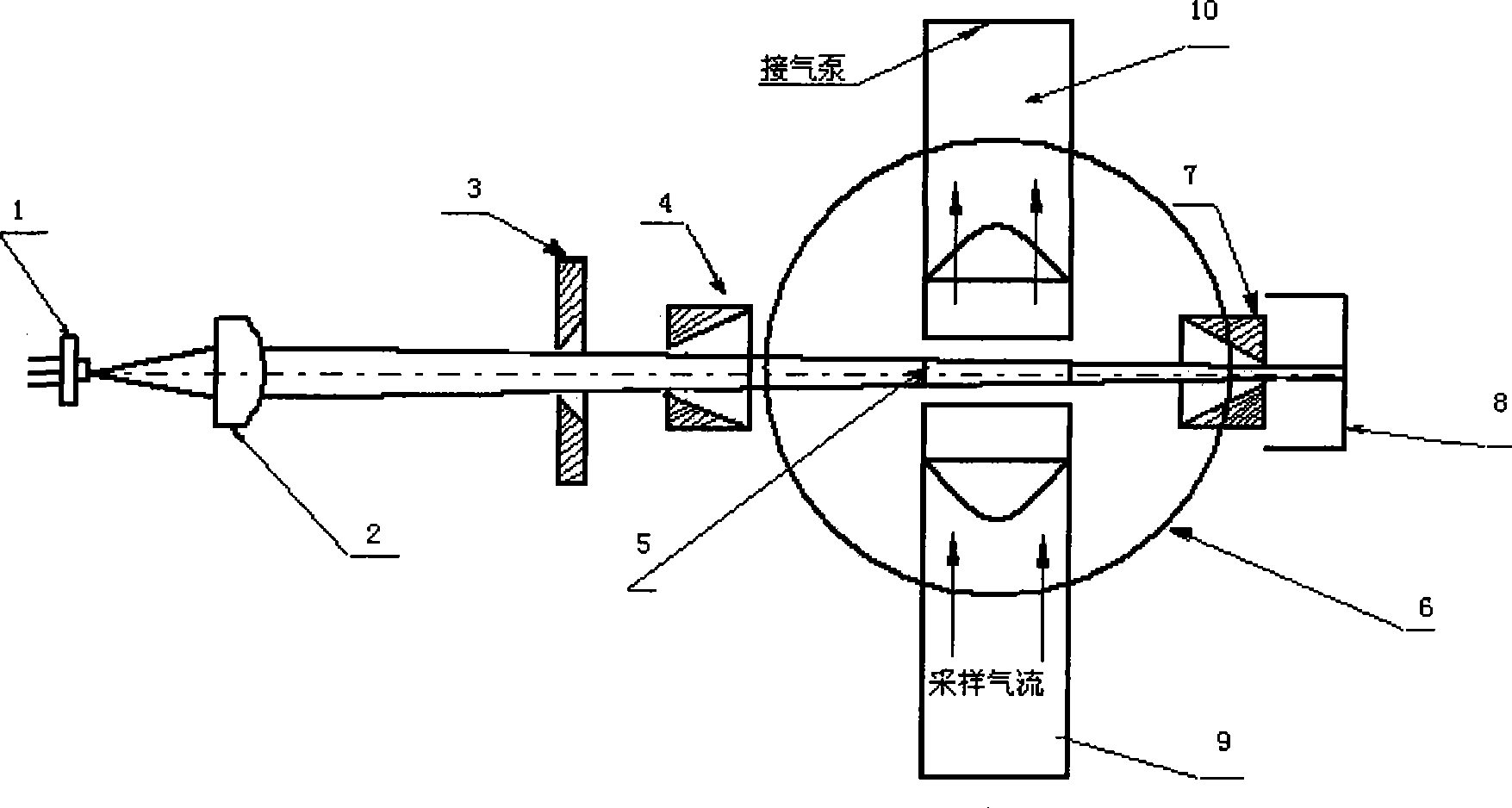

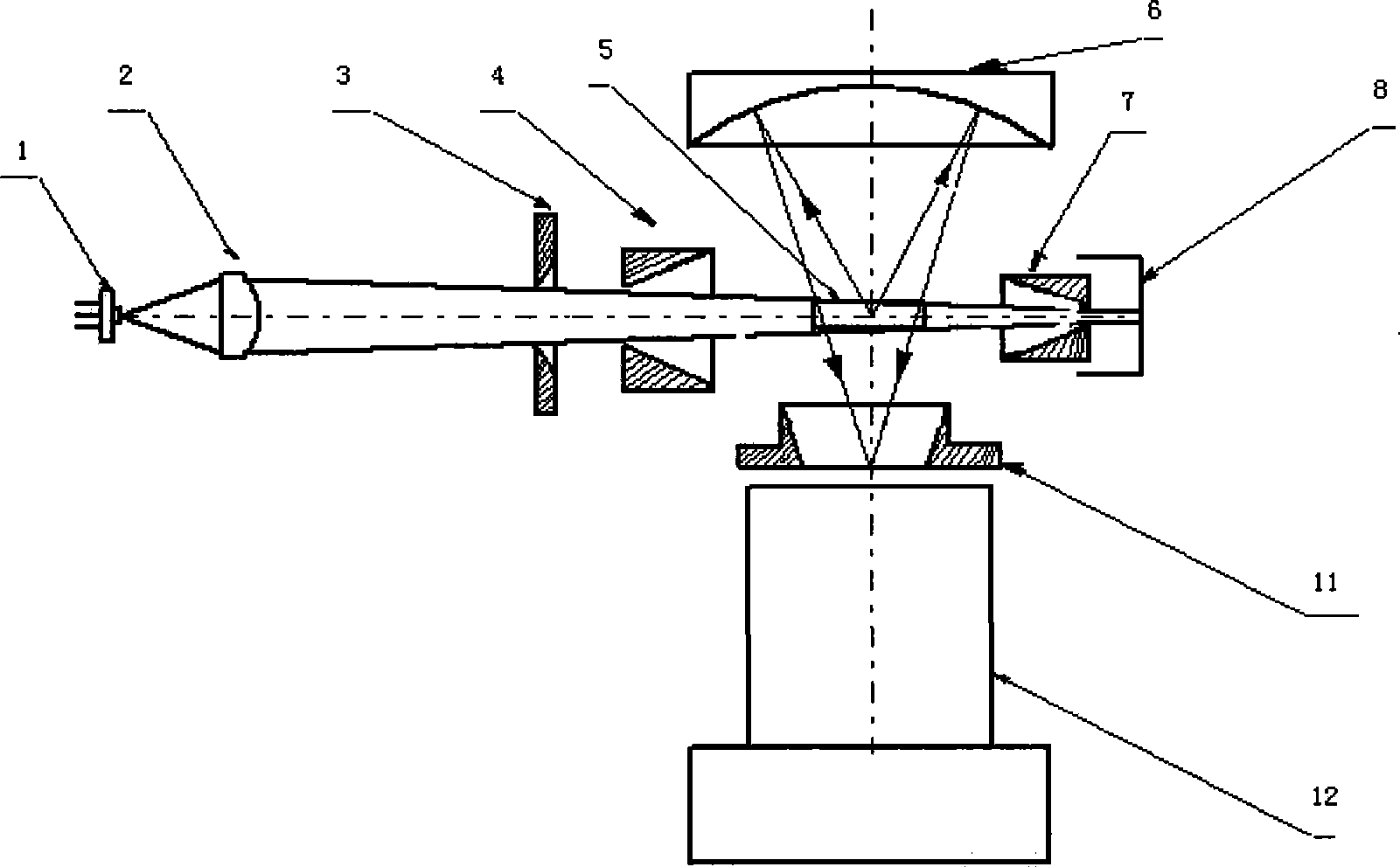

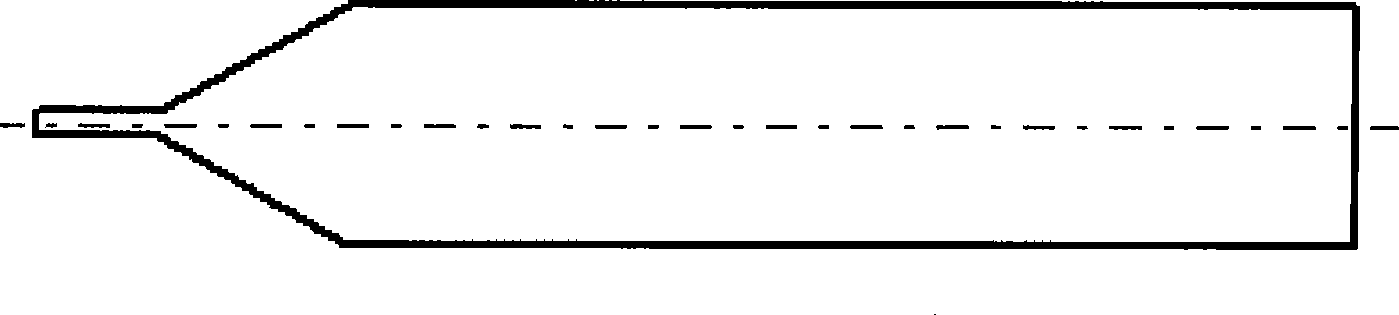

[0009] combine figure 1 , figure 2 , The optical sensor of the large-flow dust particle counter of the present invention is a right-angle scattering optical system, including an illumination system, a scattered light collection system, and an air path system. The lighting system consists of a semiconductor laser 1, an aspheric mirror 2, a first incident aperture 3, a second incident aperture 4, an exit aperture 7, and an optical trap 8. The power of the semiconductor laser 1 is 5mW and the wavelength is 650nm. The focal length aspheric mirror 2 focuses two-dimensionally, and the converging point is behind the photosensitive area, so as to ensure the uniform light intensity of the photosensitive area 5 along the axial direction, and the width of the light beam at the photosensitive area 5 is twice the width of the gas nozzle 9 . The laser beam enters the optical trap 8 after passing through the photosensitive area 5 and is absorbed by the optical trap 8 . Among them, the ape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com