Exposure apparatus

A technology of exposure device and exposure section, which is applied in the direction of exposure device of photoengraving process, exposure equipment of microlithography, cleaning and flexible articles, etc. The effect of shortening working time and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

[0109]

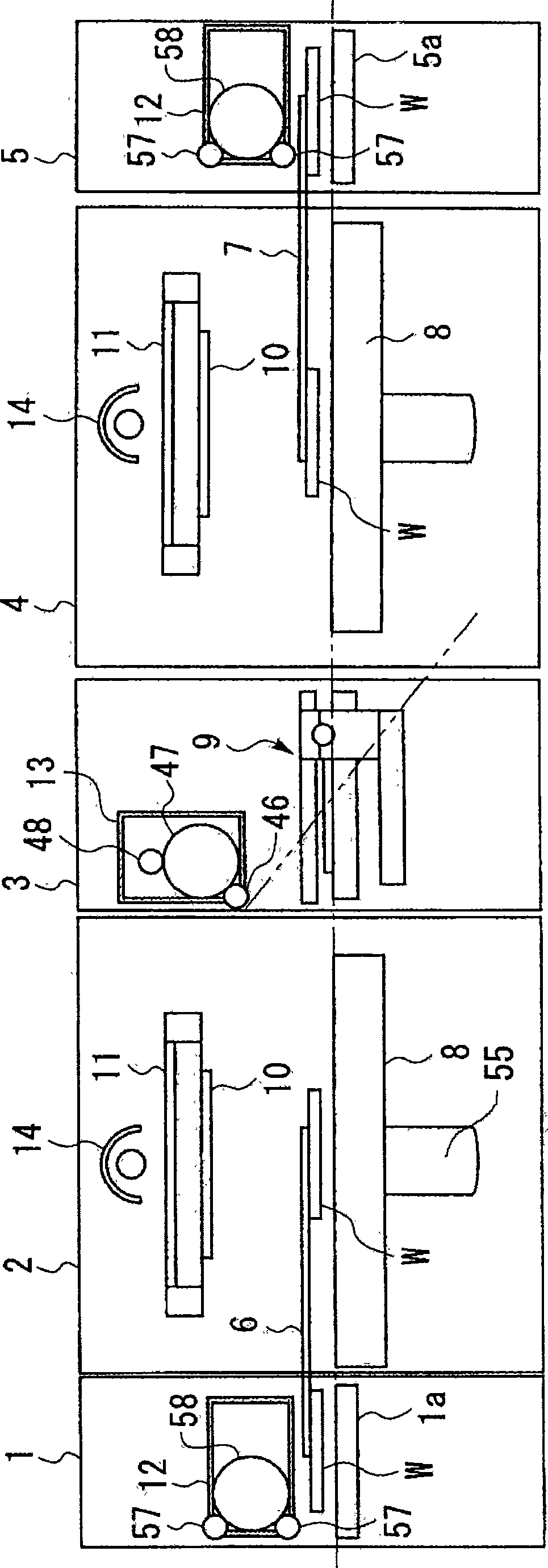

[0110] Figure 11 It is a side perspective view showing the overall structure of an exposure apparatus according to a second embodiment of the present invention. as it should Figure 11 As shown, compared with the exposure apparatus of the above-mentioned first embodiment, the second embodiment of the present invention only has the structure of the cleaning unit 21 in each exposure section 2, 4 and the control of each exposure section controller 51, 56 to Y- The Z stage 40 and the lifting mechanism 55 are different in the content of control, but the other structures are the same. Thus, in Figure 11 , for the same as in the first embodiment figure 1 The same elements of the structure shown are given with the figure 1 The same reference numerals are used, and explanations are omitted.

[0111]

[0112] The cleaning unit 21 of each exposure part 2, 4 of this embodiment is also supported by the YZ stage not shown, and moves so that a predetermined trajectory may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com