Method for making laminated travelling wave electroabsorption modulation laser with epitaxial selection region

A technology of selective area epitaxy and manufacturing method, which is applied in the field of manufacturing selective area epitaxial laminated traveling-wave electroabsorption modulation lasers, which can solve the problems of long production cycle, increased laser threshold current, complex process, etc., and achieves good far-field characteristics , small threshold current, huge competitive advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The process of fabricating a traveling-wave electroabsorption modulation laser with a stacked structure in an active region by the selective area epitaxy (SAG) technology of the present invention is described below with reference to the above-mentioned drawings.

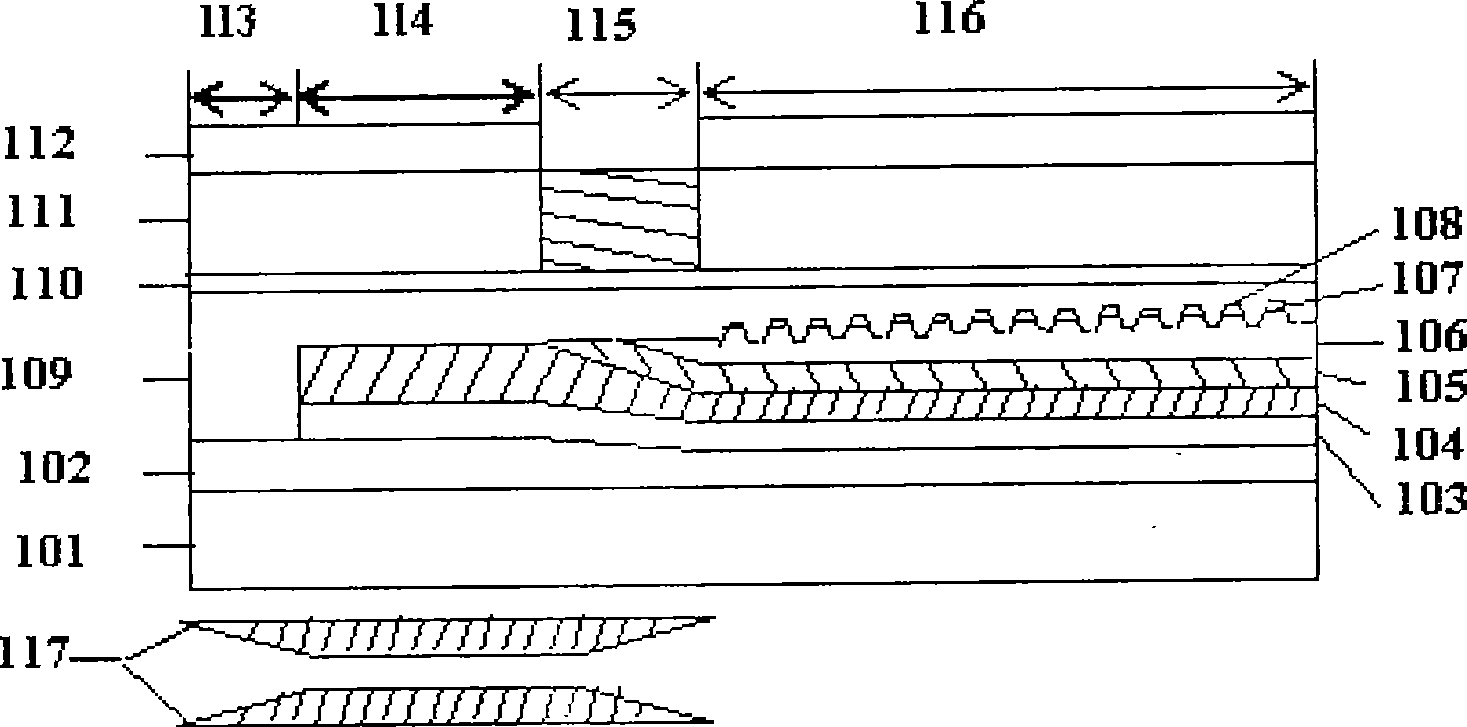

[0034] figure 1For the longitudinal structural schematic diagram of the selective area epitaxy stacked traveling-wave electroabsorption modulation laser used in the present invention, first make a wedge-shaped dielectric mask strip pattern 117 on the semi-insulating InP substrate 101, and then epitaxially epitaxially on the semi-insulating InP substrate 1 grow heavily doped n-InP buffer layer 102, 1.2Q lower confinement layer 103, modulator MQW structure 104, laser MQW structure 105, 1.2Q upper confinement layer 106 and n-InP inversion layer 107; The upper stacked MQW structure 105 (MQW of DFB) in the stacked MQW structure in the regions 113-114, together with the lower stacked MQW structure 104 (MQW of EAM) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com