Multi-axes synchronous mechanism

A technology of multi-axis linkage and rotating mechanism, which is applied in the direction of manipulators, auxiliary devices, arc welding equipment, etc., can solve the problems of high cost, poor versatility of welding special machines, unfavorable market popularization, etc., achieve low cost, small maintenance cost, and benefit the market popular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

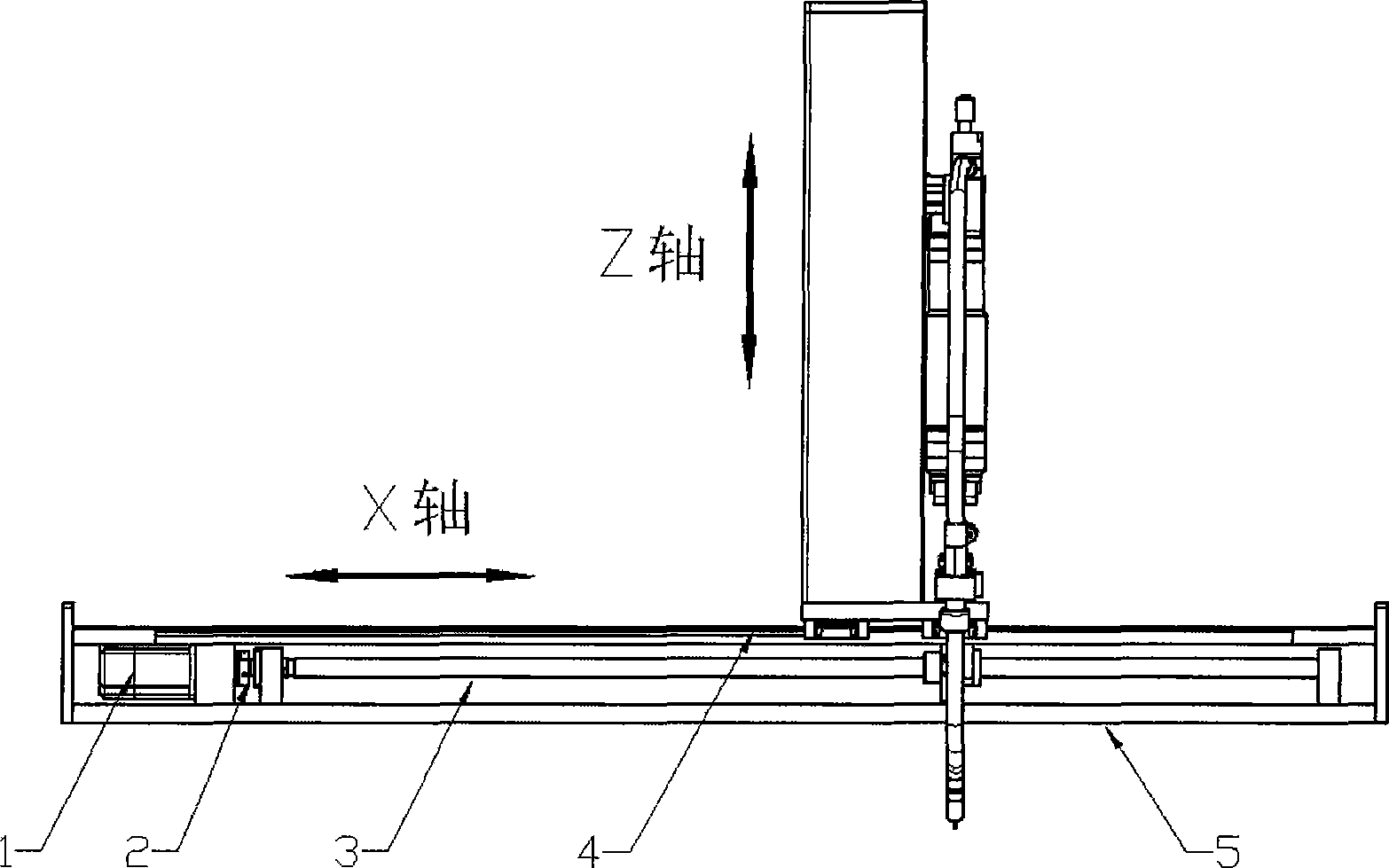

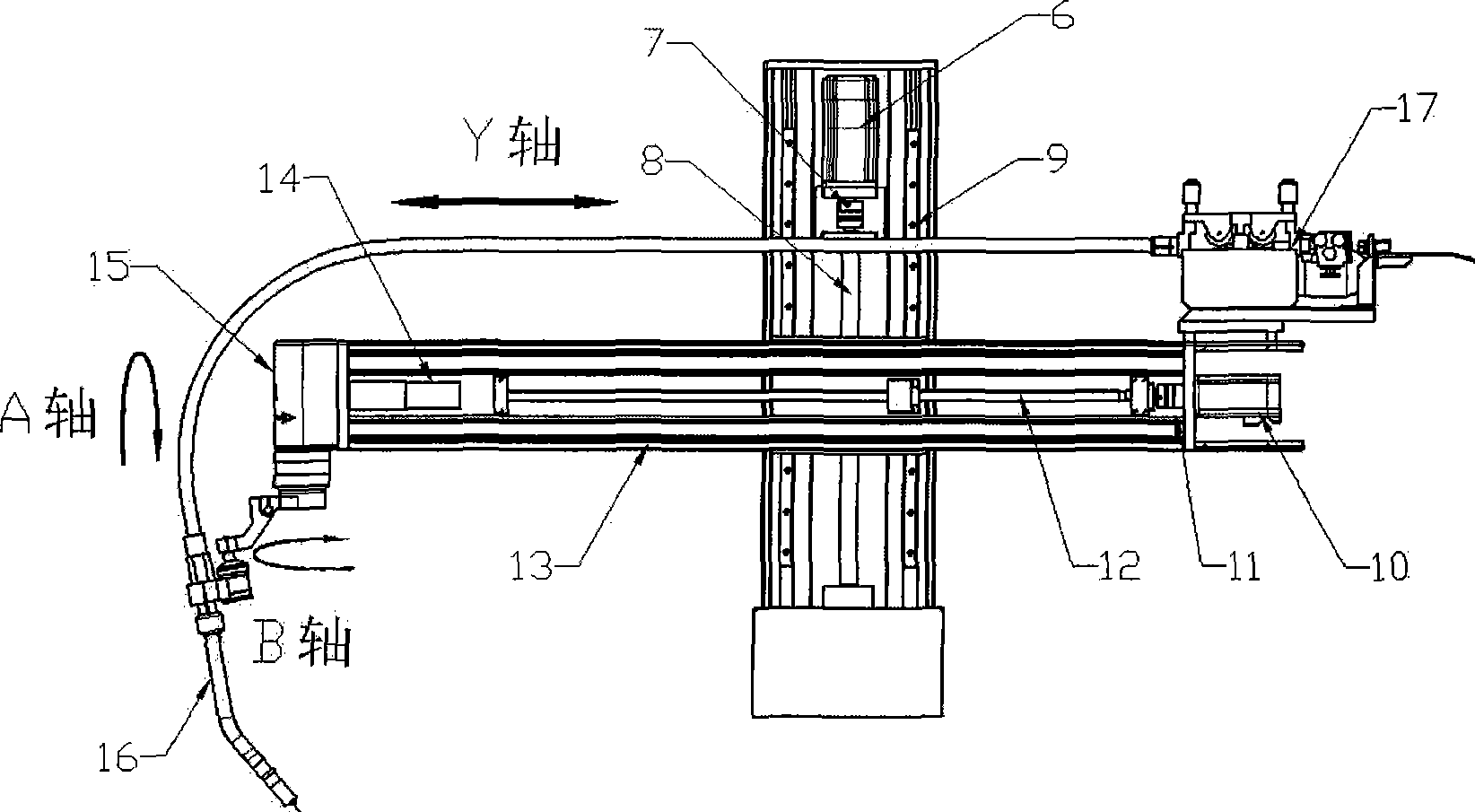

[0020] The multi-axis linkage mechanism of the present invention will be further described and illustrated below in conjunction with the accompanying drawings:

[0021] In the figure: the first servo motor 1, the second servo motor 6, the third servo motor 10; the first coupling 2, the second coupling 7, the third coupling 11; the first ball screw 3, the first The second ball screw 8, the third ball screw 12; the first linear slide 4, the second linear slide 9, the third linear slide 13; the bottom plate 5; the B-axis drive system 14; the B-axis rotating body 15: welding gun 16; Wire feeder 17.

[0022] See figure 1 with figure 2 , The present invention provides a multi-axis linkage mechanism. Specifically, the multi-axis linkage mechanism includes: a three-axis X, Y, and Z three-axis mechanical system with rectangular coordinates, a working end, an A-axis rotating mechanism containing a rotating axis A axis, a servo drive system, and a control system, where X , Y, Z three-axis m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com