Method for removing fluorine in wastewater

A waste water, packed bed technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of converter steel slag not being processed and utilized in time, and achieve huge social and economic benefits, reducing The hidden danger of human health hazards and the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

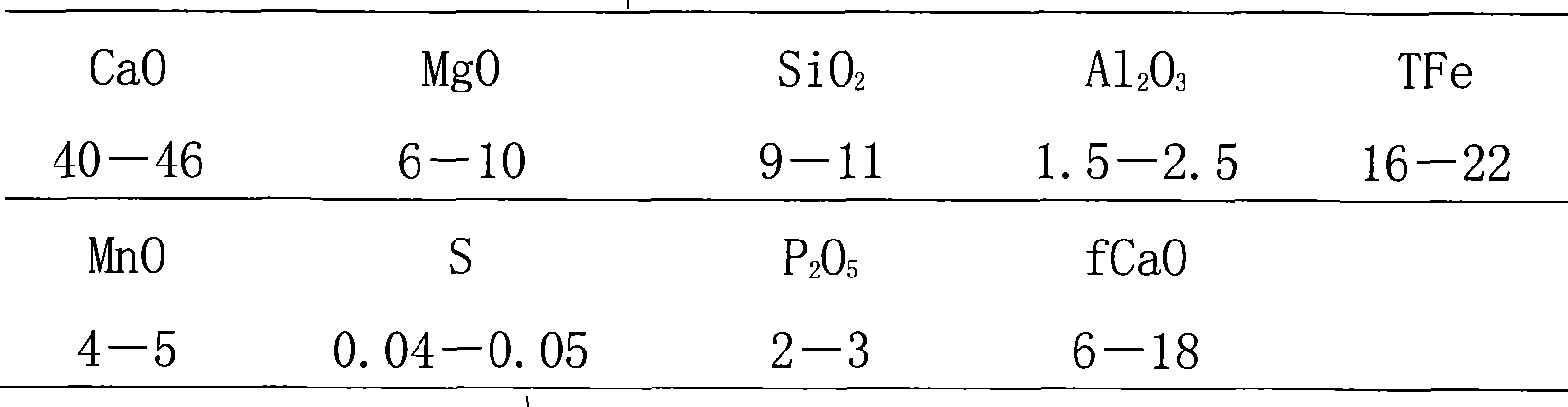

[0031] Fluoride ion concentration in wastewater is 15-30mg / L. Fill the steel slag into a primary packing bed. The particle size combination of the steel slag in the packing bed is: the ratio of 5-20mm particle size steel slag to 2-5mm particle size steel slag is 1:5; the fluorine-containing waste water flows through the steel slag packing bed from bottom to top to control The residence time of fluorine-containing wastewater is 1 hour. After the treatment of the steel slag packing bed, the concentration of fluorine in the effluent is reduced to about 5mg / L. The removal rate of fluoride ion in wastewater is 66.7%-88.3%.

Embodiment 2

[0033] Fluoride ion concentration in wastewater is 50-70mg / L. Fill the steel slag into a secondary packing bed. The particle size combination of steel slag in the first-stage packed bed is: steel slag with a particle size of 10-20mm, steel slag with a particle size of 5-10mm and steel slag with a particle size of 2-5mm at a ratio of 1:2:2; the steel slag in the second-stage packed bed The particle size combination is: the ratio of 5-20m particle size steel slag to 2-5mm particle size steel slag is 1:6. The fluorine-containing wastewater flows through the steel slag packing bed from bottom to top, and the residence time of the fluoride-containing wastewater is controlled to 40 minutes, and the concentration of fluorine in the effluent is reduced to 5-8mg / L. The removal rate of fluoride ion in wastewater is 84%-93%.

Embodiment 3

[0035]Fluoride ion concentration in wastewater is 100-150mg / L. Fill the steel slag into a three-stage packing bed. The particle size combination of steel slag in the first-stage packed bed is: steel slag with a particle size of 15-20mm, steel slag with a particle size of 10-15mm and steel slag with a particle size of 5-10mm at a ratio of 1:1:3; the steel slag in the second-stage packed bed The particle size combination is: 10-15mm particle size steel slag, 5-10mm particle size steel slag and 2-5mm particle size steel slag ratio is 1:2:5, the particle size combination of steel slag in the third stage packed bed is: 10-15mm particle size The ratio of diameter steel slag, 2-5mm particle size steel slag and 1-2mm particle size steel slag is 1:3:3. The fluorine-containing wastewater flows through the steel slag packing bed from bottom to top, and the residence time of the fluorine-containing wastewater is controlled to 30 minutes, and the concentration of fluorine in the effluent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com