Applique method to prevent heavy metal precipitation

A technology of heavy metals and decals, applied in the direction of copying/marking methods, processes for producing decorative surface effects, printing, etc., can solve problems such as poor appearance, low-lead and high-temperature decal papers are dim in color, and cannot meet customer needs, etc., to achieve Bright color, lower content, better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

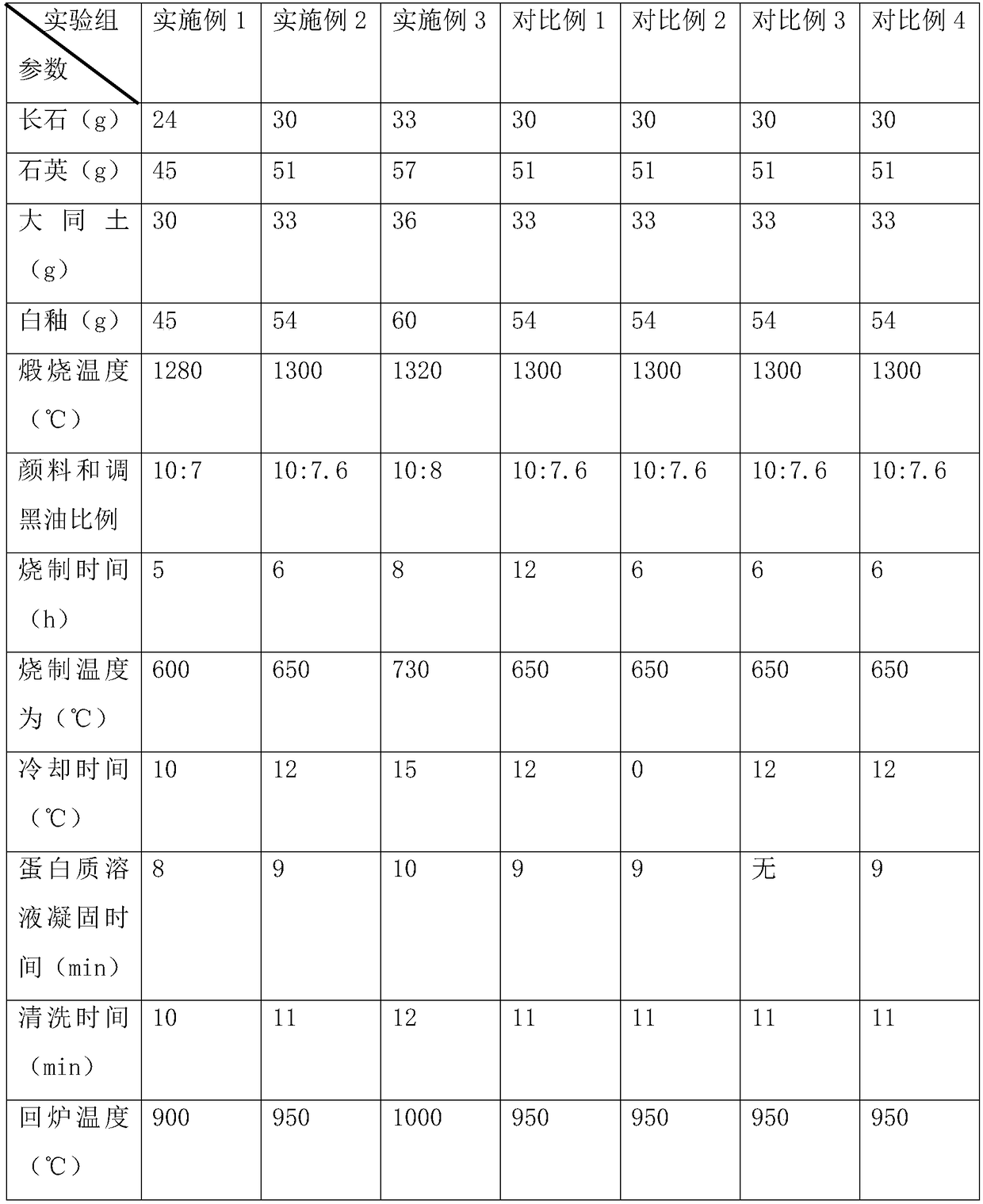

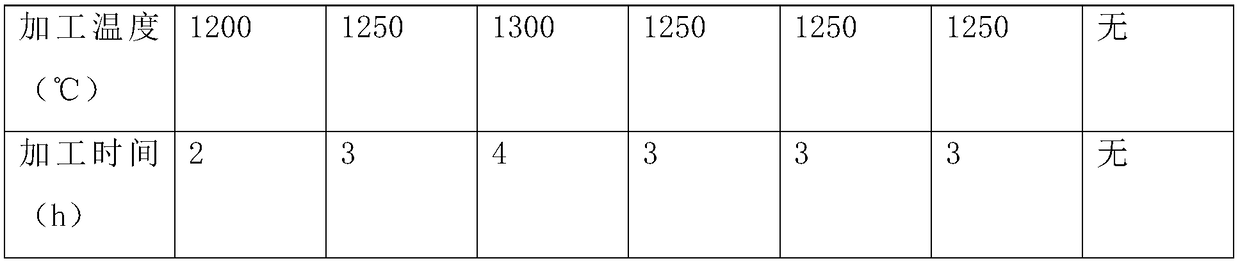

[0025] Embodiment 1: the decal method of anti-heavy metal precipitation, comprises the following steps:

[0026] S1: Raw materials: raw materials include the following components: feldspar 24g, quartz 45g, Datong soil 30g, white glaze 45g;

[0027] S2: Raw material processing: use various colored oxides and mineralizers as ingredients; Datong soil is calcined through a tunnel kiln at a calcination temperature of 1280°C; feldspar, quartz, calcined Datong soil and ingredients according to the ingredients: ball: water = 1:1.5:1 ball milling, sieving and drying the pigment after ball milling;

[0028] S3: Rolling black: blend the pigment and varnish according to the mass ratio of 10:7, and then grind to form the printed pigment;

[0029] S4: Screen printing: screen-print the printed pigments on the goose paper to make high-temperature decal paper, and apply a layer of organic adhesive on the surface of the high-temperature decal paper;

[0030] S5: Transfer printing: transfer th...

Embodiment 2

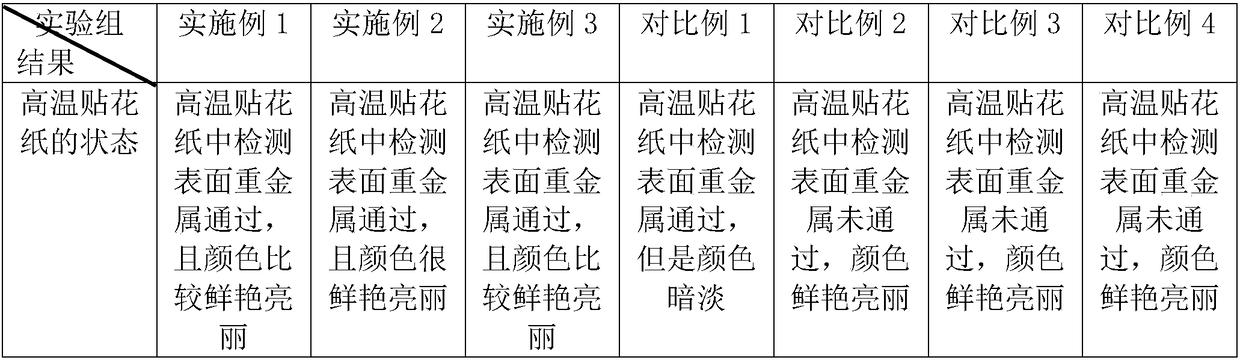

[0044] Example 2 Compared with Comparative Example 1, the high-temperature decal paper made in Comparative Example 1 passed the surface heavy metal detection, but the color was dull. The main reason is that during the firing process of high-temperature decal paper, the firing time is relatively long, and the precipitation of heavy metals in high-temperature decal paper exceeds 45%, which makes the amount of heavy metal leaching out of high-temperature decal paper excessive, so that the color of high-temperature decal paper will change. Dimming, similar to existing low lead high temperature decals.

[0045]Example 2 Compared with Comparative Example 2, the high-temperature decal paper made in Comparative Example 2 failed to pass the detection of heavy metals on the surface, and the color was bright and bright. The main reason is that there is no cooling after firing, and the heavy metal precipitation time is short, so the amount of heavy metal dissolution is very small, making ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com