Ammonia distillation process

A process, ammonia distillation technology, applied in the field of ammonia distillation process, can solve problems such as imperfection, difficulty in biochemical treatment, and increased discharge wastewater index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

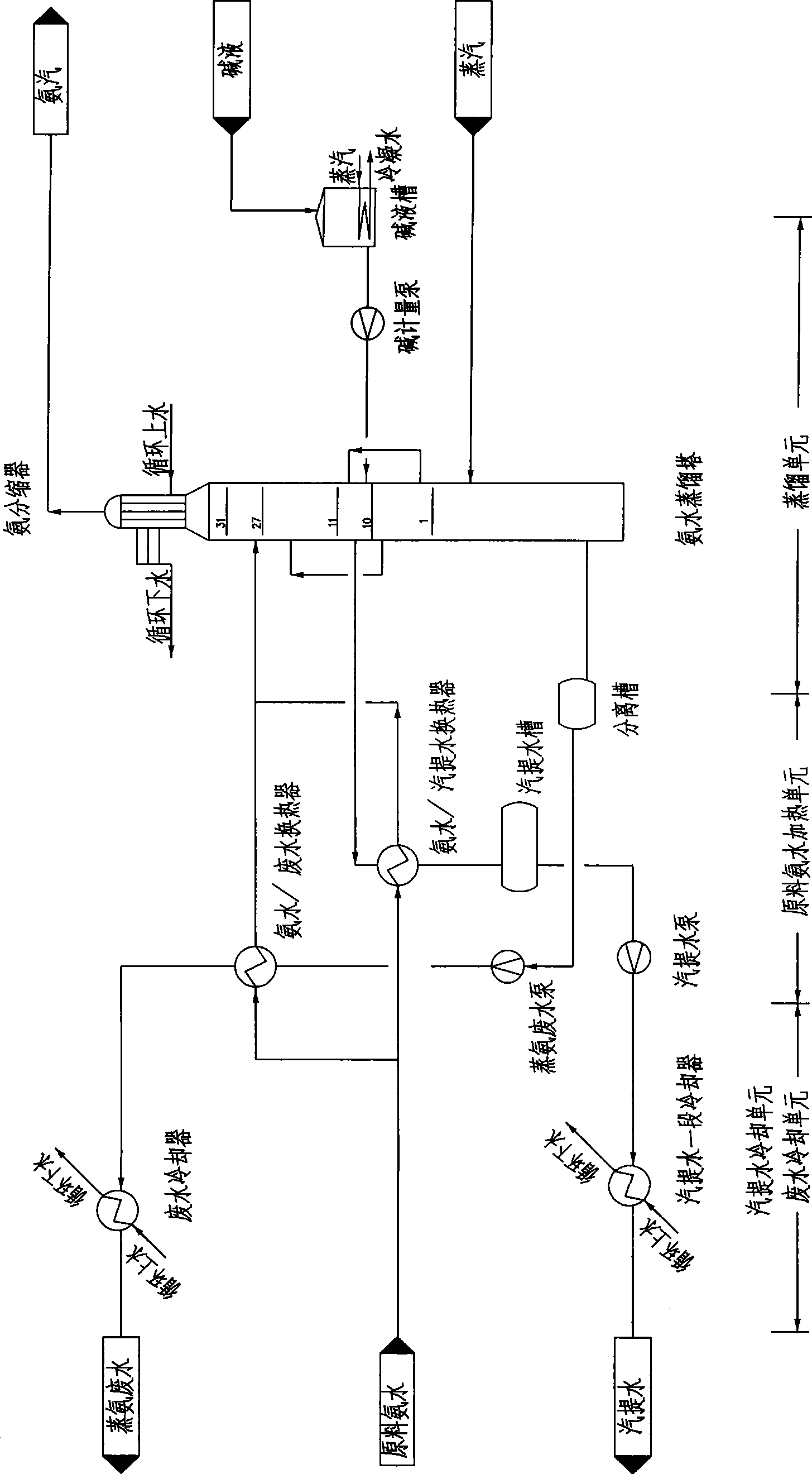

[0031] See figure 1 The ammonia distillation process of the present invention takes the rich ammonia water and residual ammonia water after washing the ammonia with coal gas as raw materials, and the main component of the ammonia water is an aqueous solution containing 5-10g / l ammonia, through the raw material ammonia water heating unit, distillation unit, stripping water cooling unit 1. Waste water cooling unit four-step process for removing ammonia from ammonia water. This process adopts the distillation process of volatile ammonia and the distillation process of decomposed and fixed ammonium in an ammonia distillation tower. The process is reasonable, occupies less land, and has a short process. The specific process is described as follows:

[0032] Combine the rich ammonia water from the washing device and the remaining ammonia water from the cooling drum unit to form raw ammonia water, heat it to 90°C through the ammonia water / waste water heat exchanger, and the ammonia w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com