High superficial hardness high temperature resistant casting titanium alloy and manufacturing method thereof

A technology for casting titanium alloy and manufacturing method, which is applied in the field of high surface hardness and high temperature resistant casting titanium alloy and its manufacturing field, and can solve the problems of low mechanical properties, poor wear resistance and large specific gravity of copper-based alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Sponge Ti, pure Al, Al-Mo (1:1) master alloy, Al-V (1:1) master alloy, Al-Cr (1:1) master alloy, sponge Zr are used as raw materials, and the particle size is required to be 5 ~16mm, according to 6.2% Al, 1.3% Mo, 1.5% V, 1.6% Cr, 1.9% Zr, the rest is Ti to prepare the alloy material, extruded on the press to form an electrode, and then the consumable electrode is subjected to a second vacuum arc Furnace smelting into alloy ingots, and finally cast titanium alloy products under the condition that the vacuum degree is less than 10Pa in the vacuum casting furnace. Such as the 11# sample in Table 4.

Embodiment 2

[0028] Sponge Ti, pure Al, Al-Mo (1:1) master alloy, Al-V (1:1) master alloy, Al-Cr (1:1) master alloy, sponge Zr are used as raw materials, and the particle size is required to be 5 ~16mm, according to 6.5% Al, 1.8% Mo, 1.7% V, 1.8% Cr, 2.0% Zr, the rest is Ti to prepare the alloy material, extruded on the press to form an electrode, and then the consumable electrode is subjected to a second vacuum arc Furnace smelting into alloy ingots, and finally cast titanium alloy products under the condition that the vacuum degree is less than 10Pa in the vacuum casting furnace. Such as the 21# sample in Table 4.

Embodiment 3

[0030] Sponge Ti, pure Al, Al-Mo (1:1) master alloy, Al-V (1:1) master alloy, Al-Cr (1:1) master alloy, sponge Zr are used as raw materials, and the particle size is required to be 5 ~16mm, according to 6.7% Al, 2.3% Mo, 2.1% V, 2.1% Cr, 2.0% Zr, the rest is Ti to prepare the alloy material, extruded on the press to form an electrode, and then the consumable electrode is subjected to a second vacuum arc Furnace smelting into alloy ingots, and finally cast titanium alloy products under the condition that the vacuum degree is less than 10Pa in the vacuum casting furnace. Such as the 31# sample in Table 4.

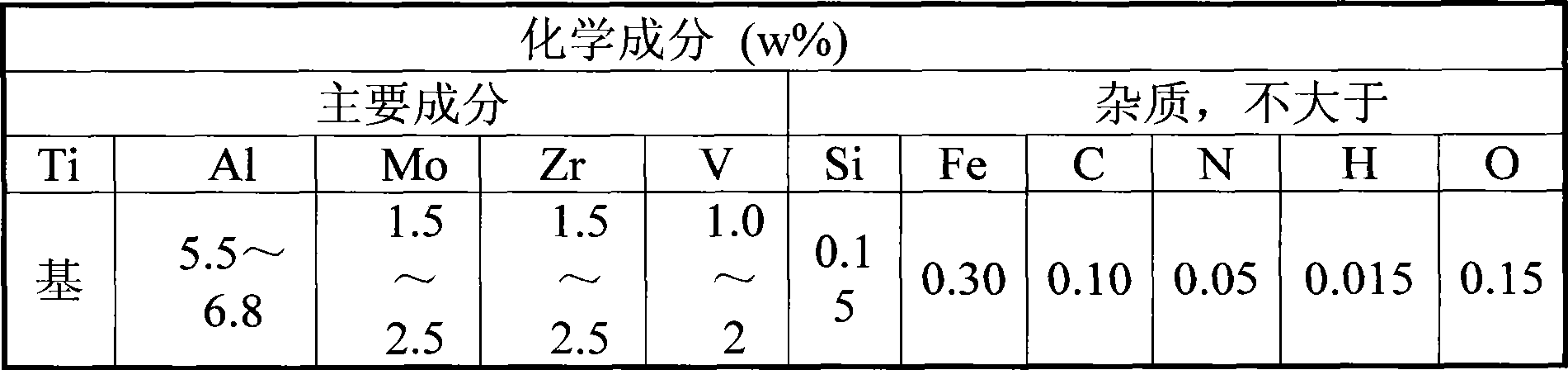

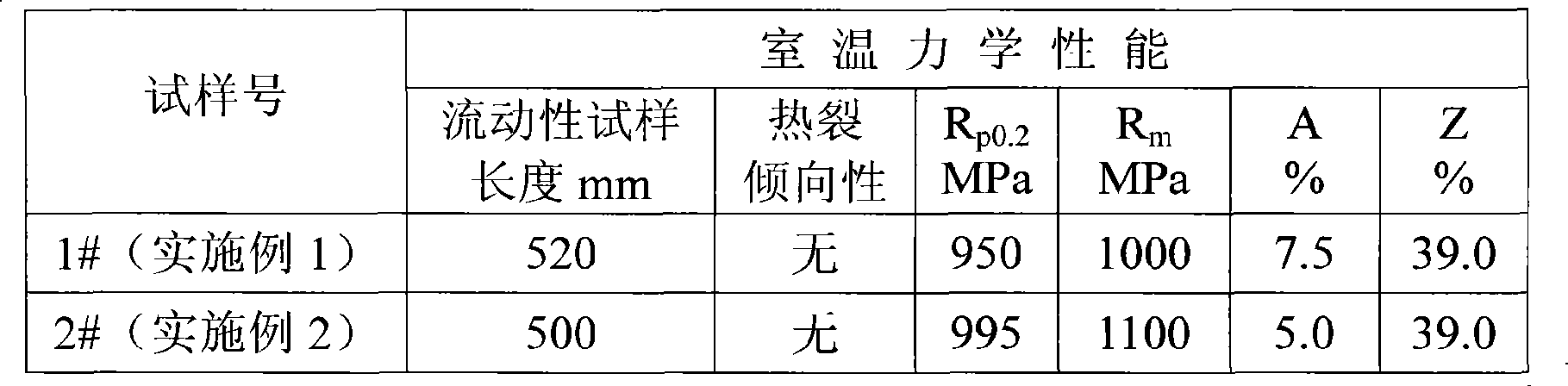

[0031] Table 3 Casting properties and room temperature mechanical properties of cast titanium alloys with this function

[0032]

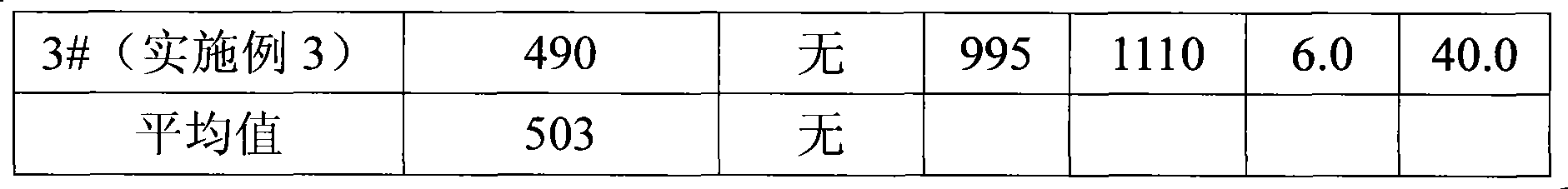

[0033]

[0034] Table 4 High temperature mechanical properties and hardness of cast titanium alloys with this function

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com