Star sensor lens and its use method in large-temperature range accurate fixed star azimuth measurement

A star sensor, temperature range technology, used in instruments, installations, optics, etc., can solve the problem of no focal length thermal deviation in aerospace optical systems, and achieve consistent accuracy, easy calibration and calibration, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

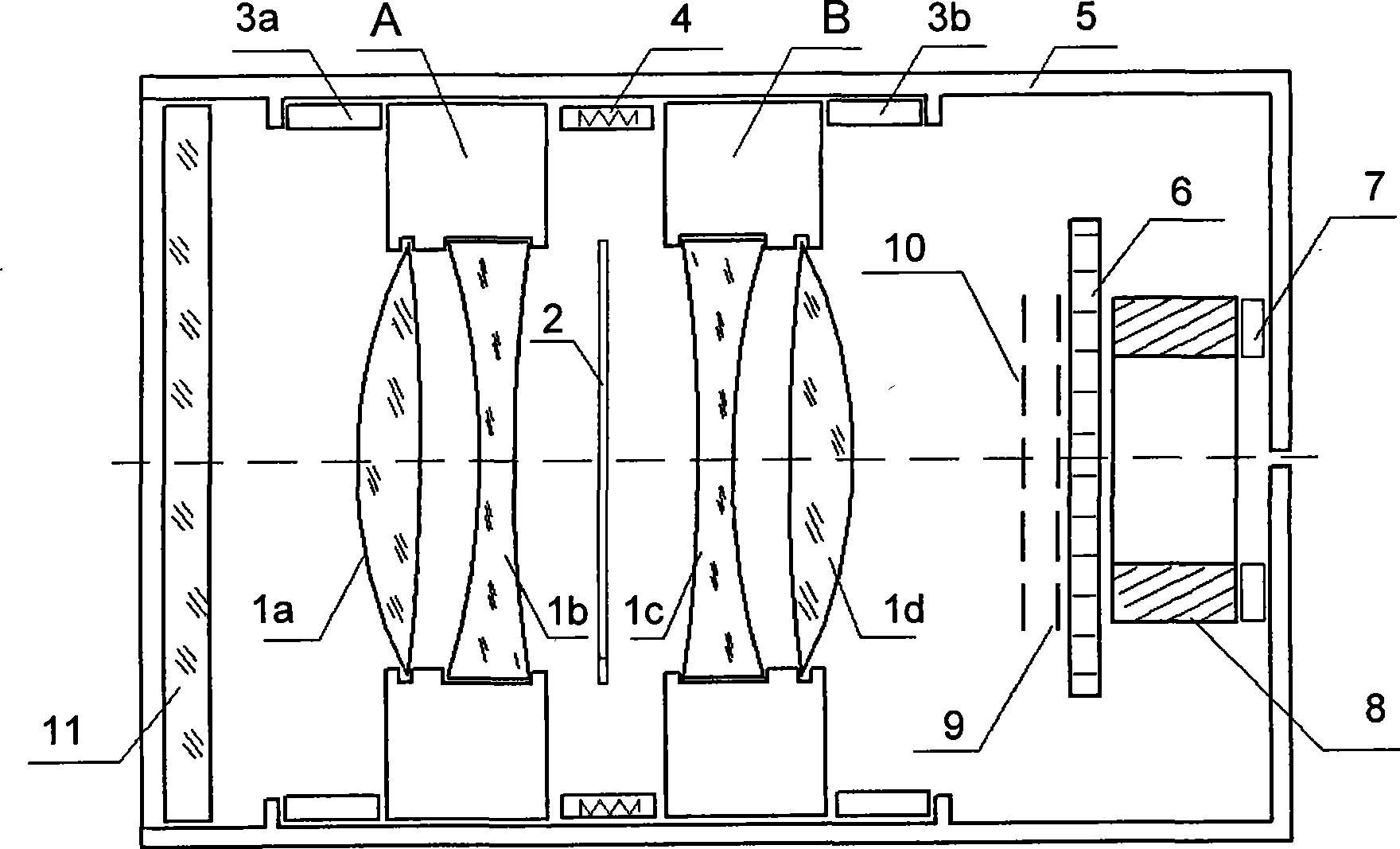

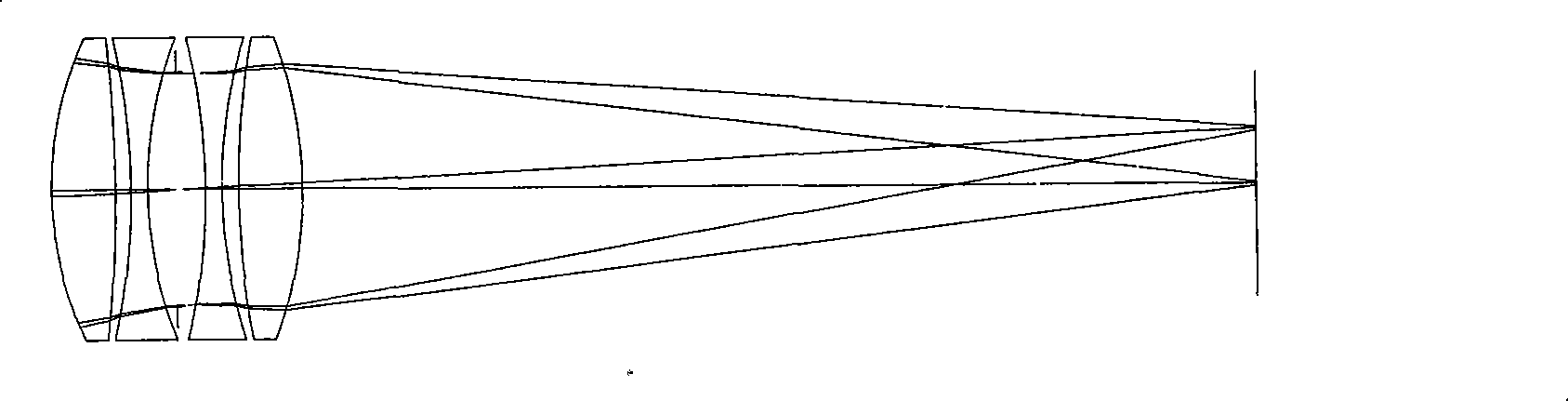

[0039] Embodiment 1: in conjunction with accompanying drawing:

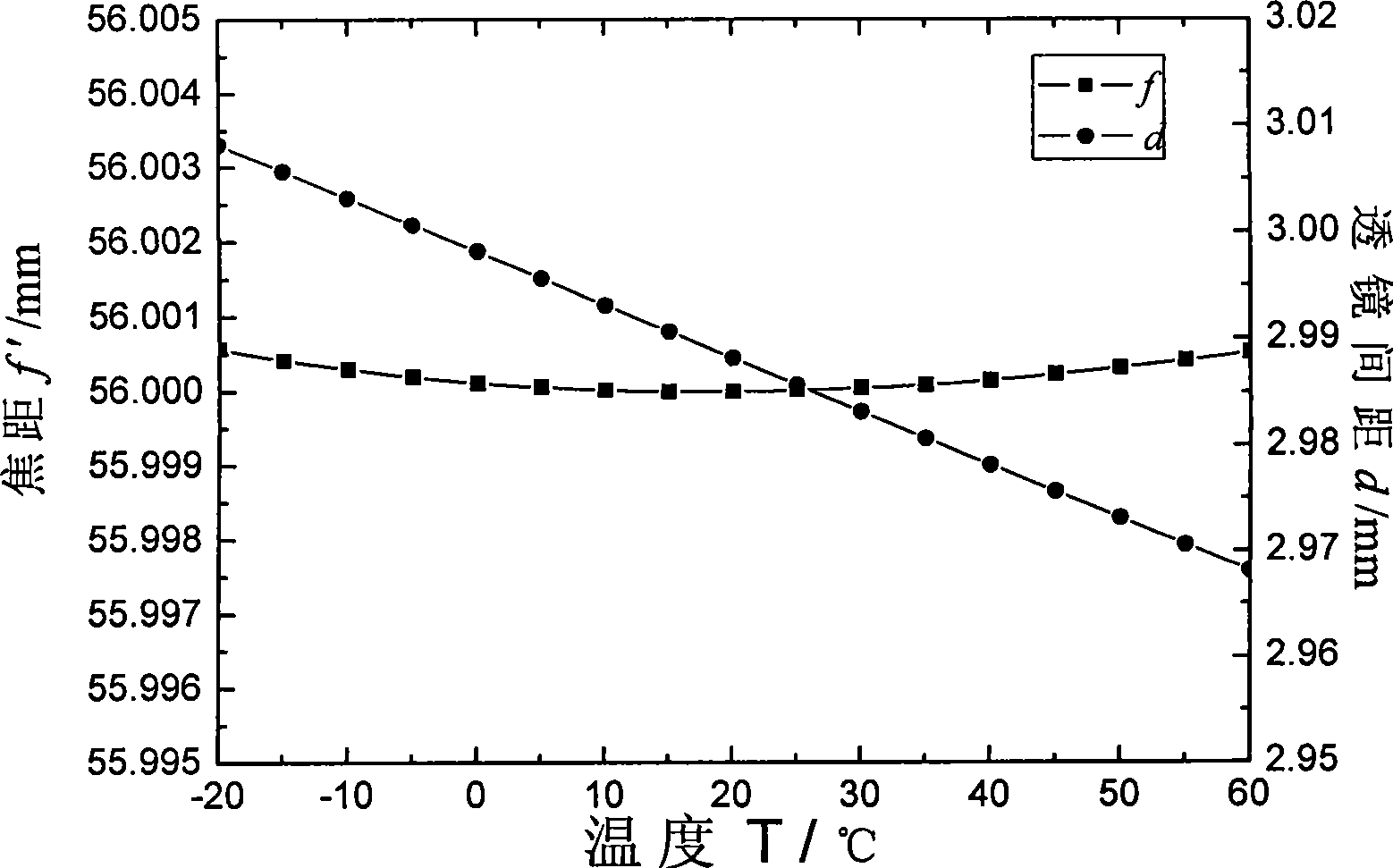

[0040] Lens 1a, 1b, diaphragm 2 and lenses 1c, 1d form a four-piece lens group of symmetrical objective lens. 3a and 3b are telescopic rings, the thermal deformation of which can fine-tune the spacing of the lens groups (the elastic ring 4 plays the role of reset and fastening). The material of the telescopic rings is aluminum alloy with a thickness of 4.64mm (20°C). Coefficient = 27×10 -6 / °C. The image sensor 6 is located on the right side of the rear focal plane 10 of the objective lens. The support ring 8 plays a role in fine-tuning the axial position of the image sensor 6, so that the photosensitive surface 6 of the sensor is always aligned with the selected defocus surface 9.

[0041] 5 is a metal lens barrel, the material is titanium alloy TC4, and the coefficient of thermal expansion is 9.1×10 -6 / °C. 11 is optical filter (and protection window). The lens and image sensor are fixed in the lens barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com