Hollow coupling reactor

A technology of coupled reactance and hollow core, applied in the direction of inductors, fixed inductors, circuits, etc., can solve the problems of small leakage reactance, small coupling coefficient, and high coupling degree of reactors, and achieve small leakage reactance, good linearity, and coupling degree high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

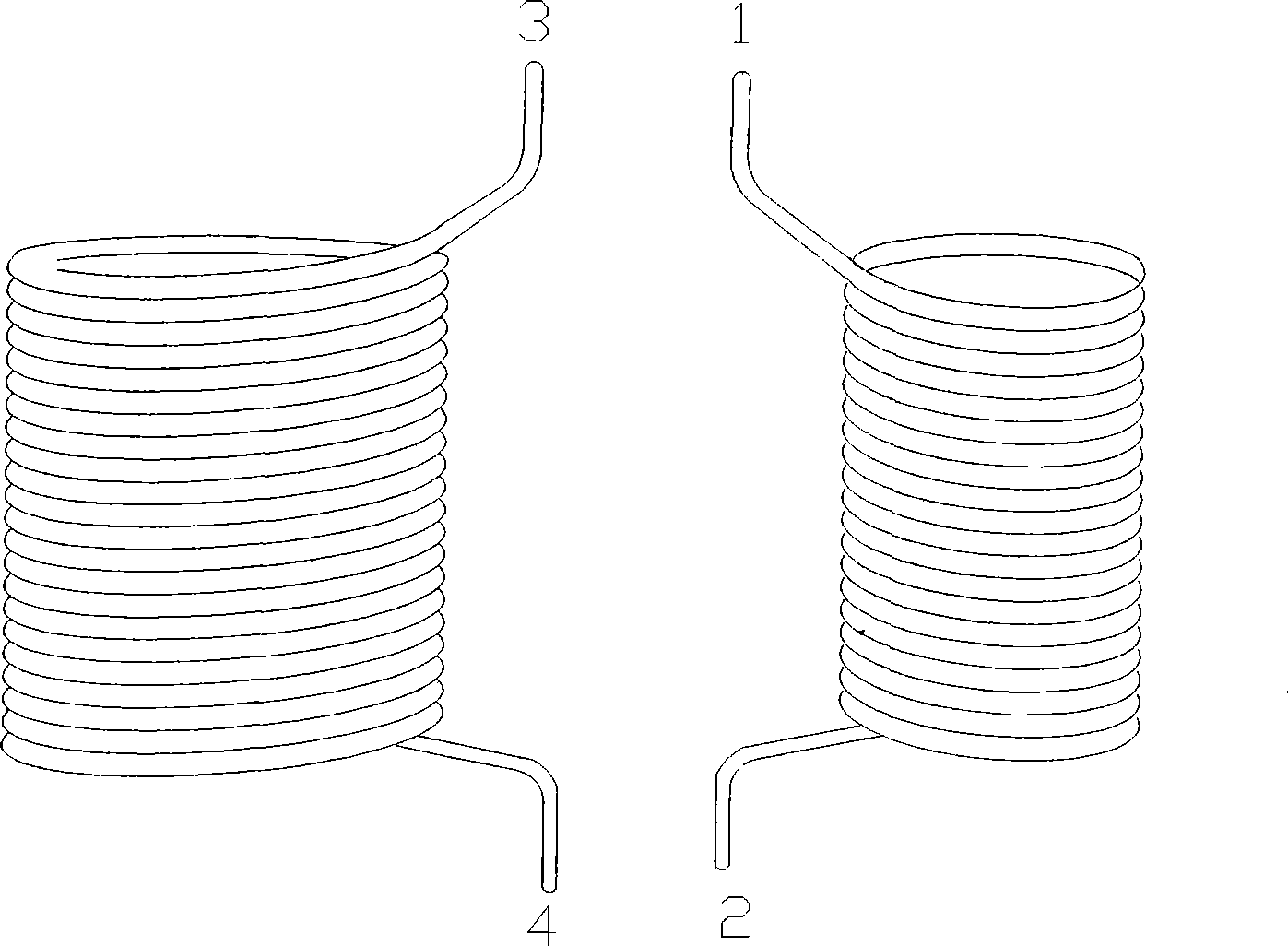

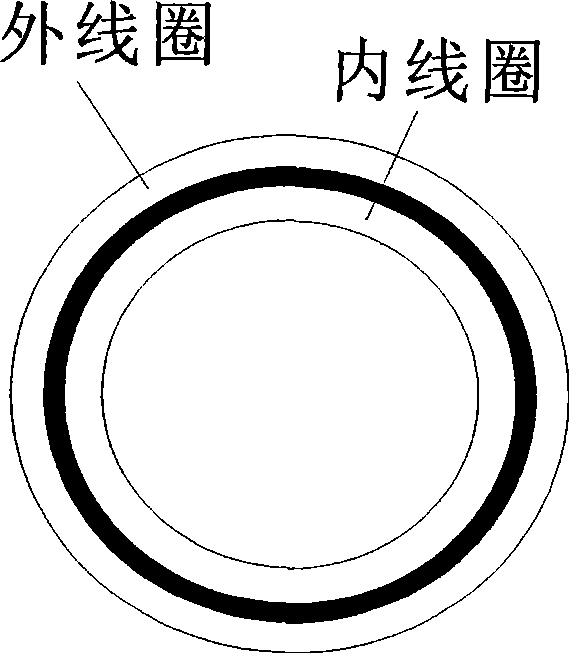

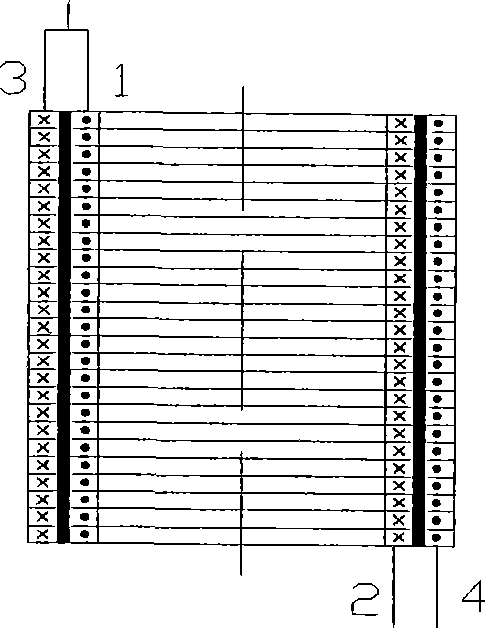

[0030] As shown in FIG. 1(A), the coupling coil of the present invention is composed of an inner coil and an outer coil, and the wires of the inner and outer coils are wound in opposite directions and wound into a hollow coaxial cylinder. The inner coil input terminal 1, the inner coil output terminal 2, the outer coil input terminal 3, and the outer coil output terminal 4. Each coil has only a single-layer winding, and the split winding method is not used.

[0031] As shown in Figure 1(B), 1-2 and 3-4 are two coils coupled to each other, the inner and outer coils are wound radially, and the winding directions of the two coils are opposite, as shown in Figure 1( In A), the inner coil 1-2 is wound clockwise, and the outer coil 3-4 is wound counterclockwise. The inter-turn insulation of the coil and the insulation withstand voltage level of the interlayer insulation are determined according to the voltage level of the system where the coil is located; in order to reduce the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com