Sheet for sealing rear surface of solar cell

A technology for solar cells and sealing, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as the influence of solar cell power output characteristics, poor appearance, and reduced barrier properties, and achieve excellent power output characteristics, excellent barrier properties, The effect of preventing material aging

Active Publication Date: 2009-07-08

TOPPAN INC +1

View PDF7 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] Of course, this problem also occurs for the above-mentioned fluorine-based resins. When the above-mentioned acceleration test is carried out, not only the appearance is poor due to delamination over time, but also the barrier properties required as a backside sealing sheet are also reduced, which may affect solar energy. The power output characteristics of the battery are affected

[0010] From the above analysis, it can be seen that not only weather resistance (hydrolysis resistance) is required as a film base material, but also the adhesive used to paste the film base material must also have hydrolysis resistance, but the current situation is still unresolved.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0212] Adhesive 1 was used to manufacture samples of the structures 1 to 4 above.

Embodiment 2

[0214] Using Adhesive 2, samples of the above-mentioned structures 1 to 4 were produced.

Embodiment 3

[0216] Using Adhesive 3, samples of the above structures 1 to 4 were produced.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| edge crush strength | aaaaa | aaaaa |

| heat shrinkage ratio | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Login to View More

Abstract

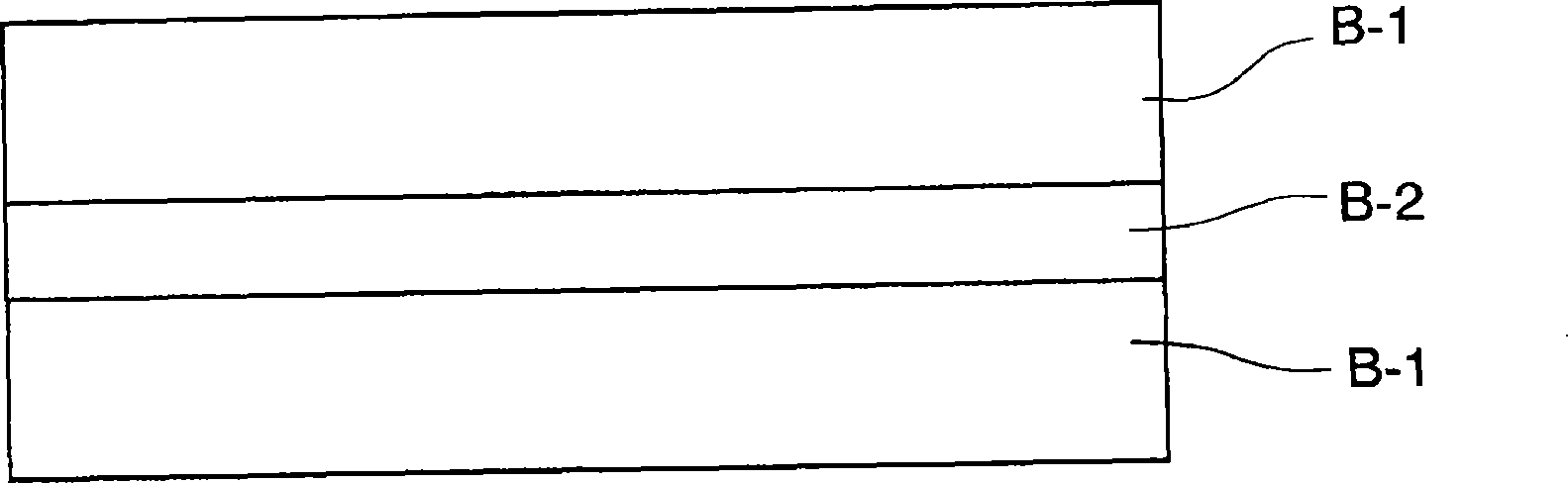

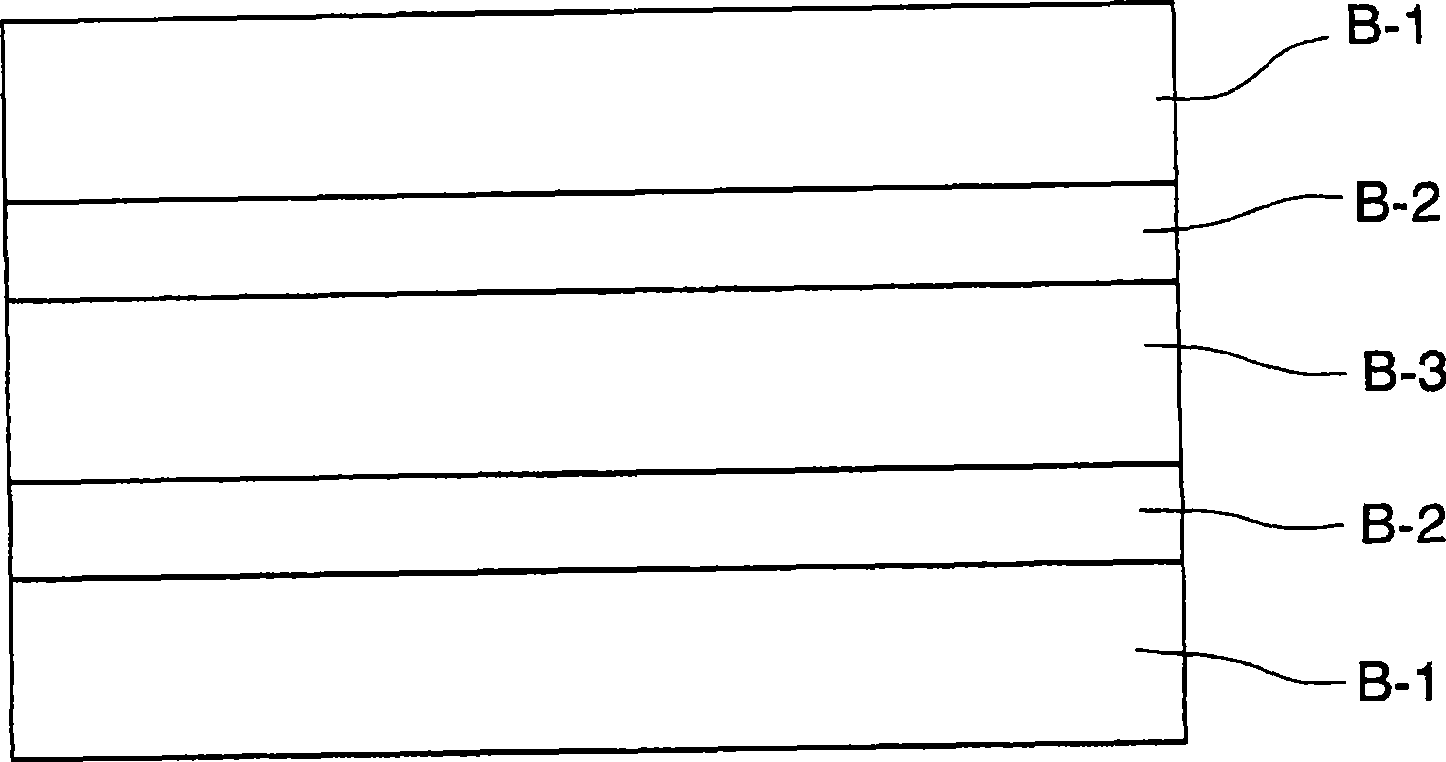

There is provided a solar cell back surface sealing sheet which prevents a material degradation due to hydrolysis in an actual environment in which it is used as a solar cell module and in a high temperature and humidity acceleration test of a solar cell module. The sheet also maintains electrical output characteristics as a solar cell, and excels in antiweatherability. The solar cell back surface sealing sheet has a laminated body formed by laminating at least two or more layers of a base material with a polyurethane adhesive, wherein the polyurethane adhesive includes an adhesive with hydrolysis resistance satisfying the following two conditions; condition (1), wherein laminate strength after storing in a HAST chamber, which is an acceleration test equipment by pressurized steam, for 168 hours at 105 DEG C and 1.05 atm is at least 1N / 15mm or more, and condition (2), wherein separation between the substrates due to delamination does not occur after storing in a HAST chamber, which is an acceleration test equipment by pressurized steam, for 168 hours at 105 DEG C and 1.05 atm.

Description

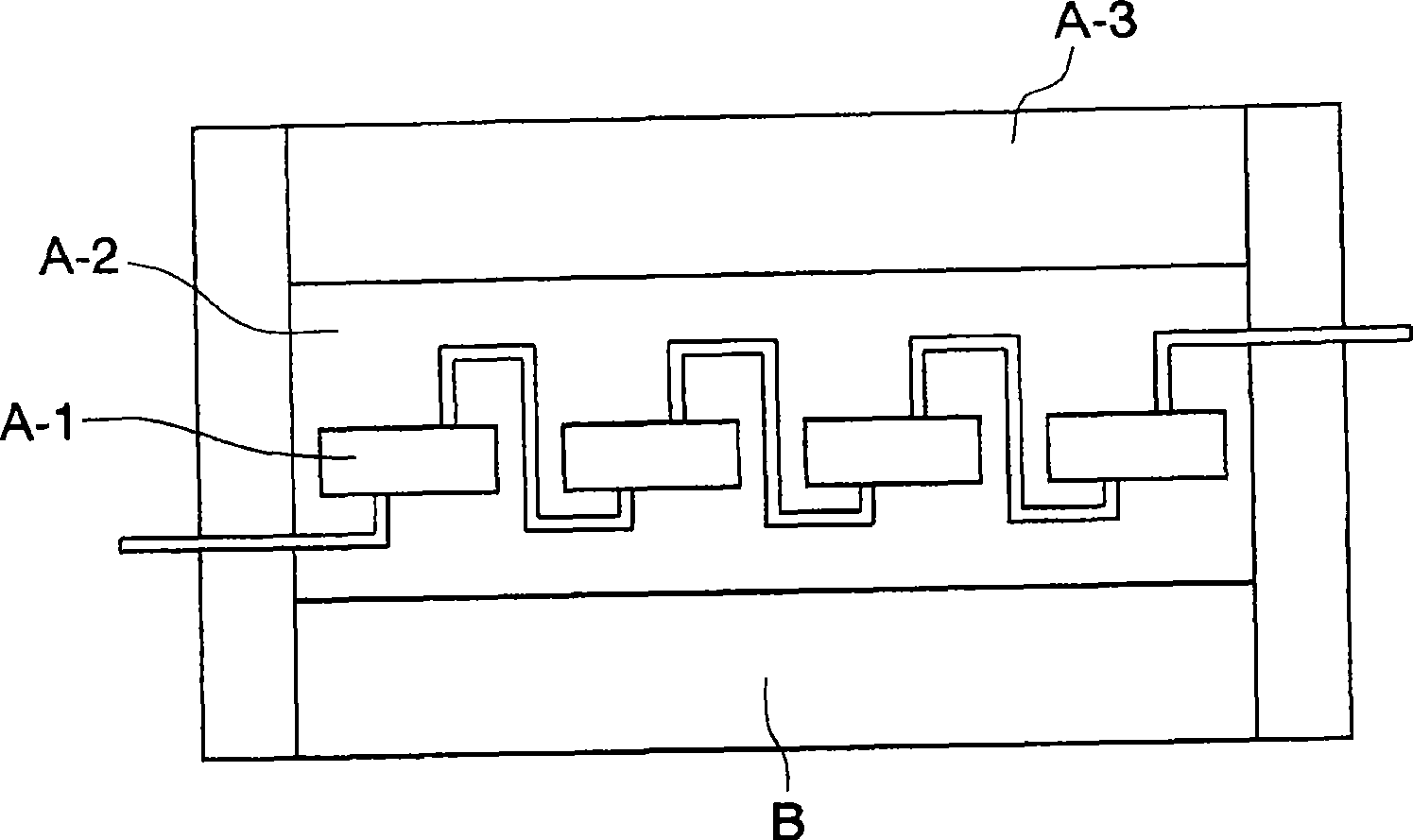

technical field [0001] The present invention relates to a sheet for sealing the back of a solar cell with excellent hydrolysis resistance. Defective appearance due to delamination can also be used as a sheet for back sealing of solar cells that has excellent barrier properties and can maintain the power output characteristics of solar cells well. This application claims the priority of Japanese Patent Application No. 2006-171534 filed in Japan on June 21, 2006, and uses the contents thereof here. Background technique [0002] In recent years, Japan and overseas countries have paid great attention to the issue of global warming, and have made various efforts to curb carbon dioxide emissions. The increase in the consumption of fossil fuels leads to the increase of carbon dioxide in the atmosphere, and through the greenhouse effect, the global temperature rises, which has a great impact on the global environment. In order to solve this global environmental problem, various st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L31/04B32B9/00B32B15/095B32B27/36B32B27/40C09J175/06C09J175/14

CPCC08G18/6229B32B7/12C08G18/725C09J175/04Y02E10/50H01L31/048C08G18/44B32B27/06H01L31/049Y10T428/31515Y10T428/31551B32B27/40C09J175/14

Inventor 铃田昌由吉永雅信示野郁乃辻井笃安井文五前田诚治

Owner TOPPAN INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com