Flexible metal organic framework/gelatin composite film as well as preparation method and application thereof

A technology of composite film and organic framework, which is applied in generators/motors, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of increased output power, low output power, and increased current, achieving high surface charge, Easy to prepare and the effect of increasing the evaporation rate of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Mix 320ml copper hydroxide nanowire solution with 6.4ml concentration of 0.1wt% B-type gelatin aqueous solution, after magnetic stirring for 10 minutes, vacuum filter on slow filter paper to obtain paper-based hydroxide nanowire / gelatin composite film, wherein the diameter of the slow filter paper used is 4.7 cm.

[0054] (2) Soak the copper hydroxide nanowire / gelatin composite film of paper base in the aqueous solution of 2.5wt% glutaraldehyde in 10ml concentration, remove the aqueous solution of glutaraldehyde after crosslinking 24 hours, add 15ml concentration and be 5mmol / L of 2,3,6,7,10,11-hexahydroxytriphenylenebenzene solution (the solvent is a mixture of water and dimethylformamide with a volume ratio of 10:1), react at 25°C for 2 hours Finally, a paper-based Cu-CAT-1 / gelatin composite film was obtained.

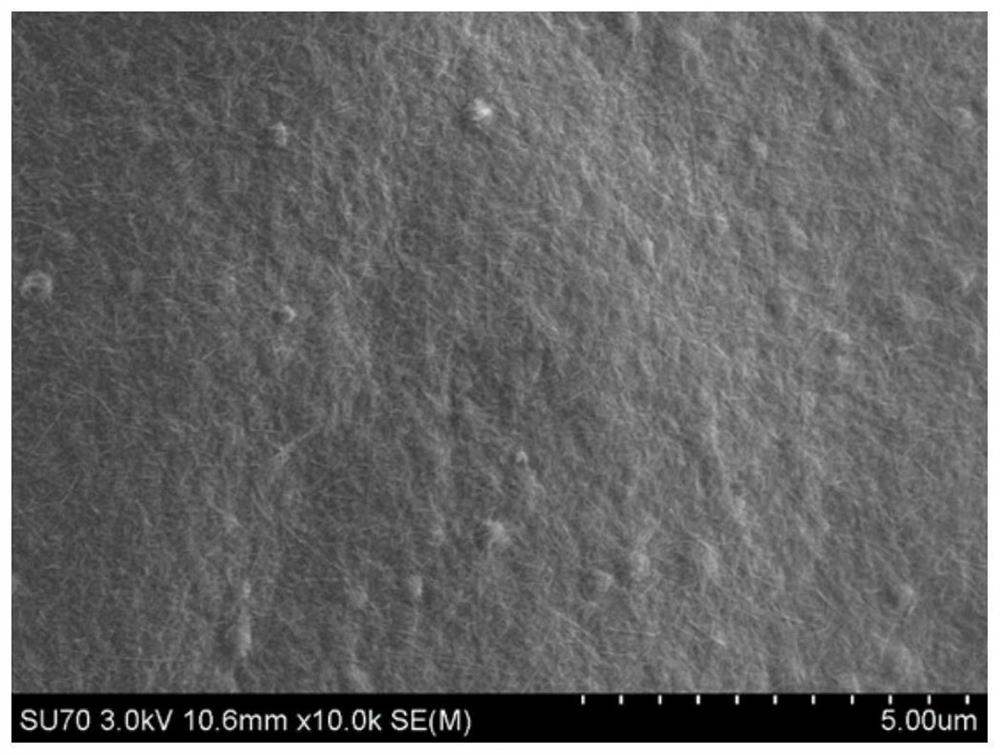

[0055] Depend on figure 1 It can be seen that copper hydroxide nanowires and gelatin were deposited on the filter paper, forming a dense copper hydrox...

Embodiment 2

[0057] (1) Mix 320ml copper hydroxide nanowire solution with 6.4ml concentration of 0.1wt% B-type gelatin aqueous solution, after magnetic stirring for 10 minutes, vacuum filter on slow filter paper to obtain paper-based hydroxide nanowire / gelatin composite film, wherein the diameter of the slow filter paper used is 4.7 cm.

[0058] (2) Soak the copper hydroxide nanowire / gelatin composite film of paper base in the aqueous solution of 2.5wt% glutaraldehyde in 10ml concentration, remove the aqueous solution of glutaraldehyde after crosslinking 24 hours, add 15ml concentration and be 5mmol / L of 2,3,6,7,10,11-hexahydroxytriphenylenebenzene solution (the solvent is a mixture of water and dimethylformamide with a volume ratio of 10:1), react at 55°C for 2 hours Finally, a paper-based Cu-CAT-1 / gelatin composite film was obtained.

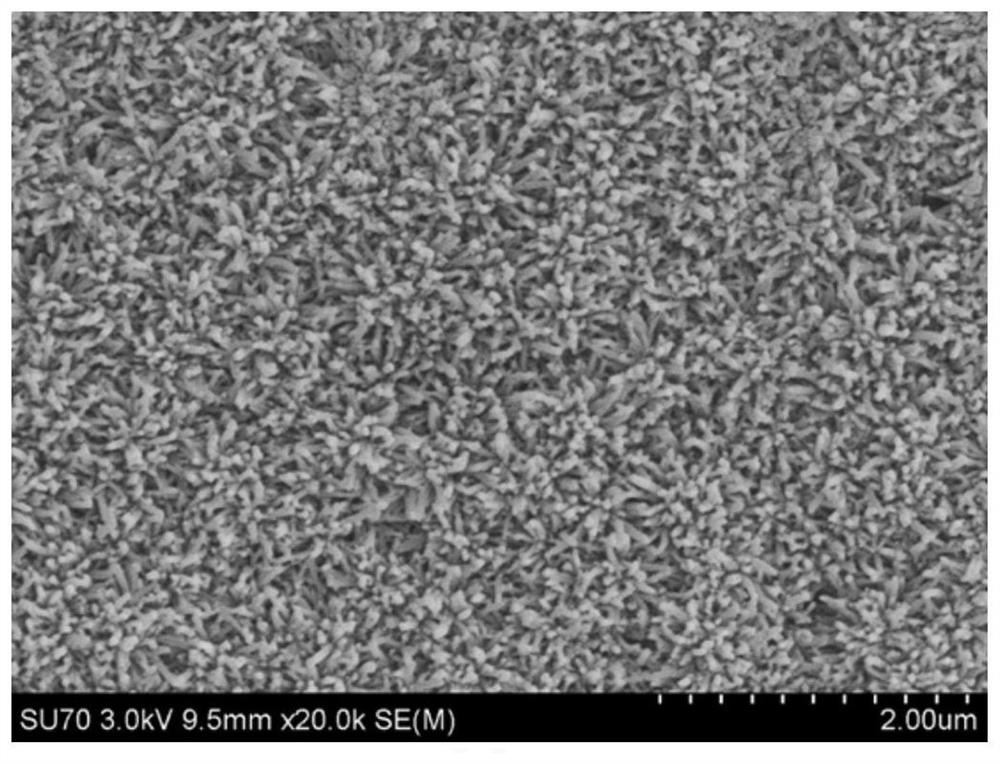

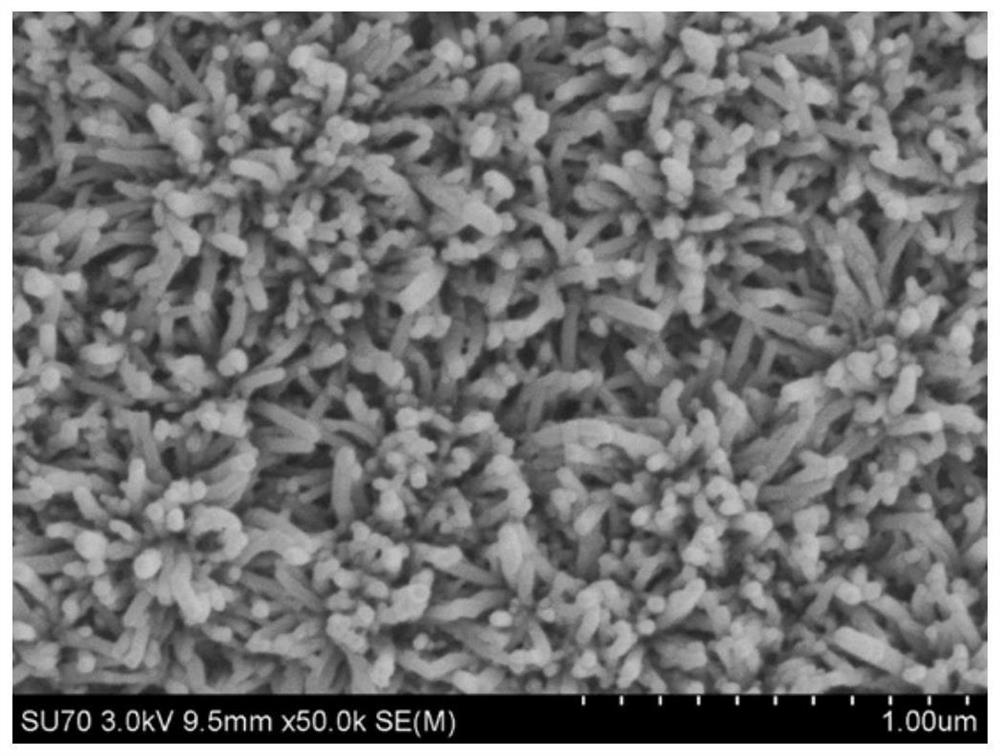

[0059] The paper-based Cu-CAT-1 / gelatin composite film is a nanorod array morphology with a unique hierarchical porous structure, excellent solar light...

Embodiment 3

[0061] (1) Mix 320ml copper hydroxide nanowire solution with 6.4ml concentration of 0.1wt% B-type gelatin aqueous solution, after magnetic stirring for 10 minutes, vacuum filter on slow filter paper to obtain paper-based hydroxide nanowire / gelatin composite film, wherein the diameter of the slow filter paper used is 4.7 cm.

[0062] (2) Soak the copper hydroxide nanowire / gelatin composite film of paper base in the aqueous solution of 2.5wt% glutaraldehyde in 10ml concentration, remove the aqueous solution of glutaraldehyde after crosslinking 24 hours, add 15ml concentration and be 5mmol / L of 2,3,6,7,10,11-hexahydroxytriphenylenebenzene solution (the solvent is a mixture of water and dimethylformamide with a volume ratio of 10:1), react at 85°C for 2 hours Finally, a paper-based Cu-CAT-1 / gelatin composite film was obtained.

[0063] The paper-based Cu-CAT-1 / gelatin composite film is a nanorod array morphology with a unique hierarchical porous structure, excellent solar light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com