Production method of near-infrared photo-responsive sterilization-deadhesion wrinkle surface

A near-infrared light-responsive, wrinkling technology, applied in disinfection, coating, irradiation and other directions, can solve the problems of long-term sterilization, inability to remove bacteria, hinder bacterial adhesion, etc., and achieve simple process and excellent photothermal conversion. Efficient, simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

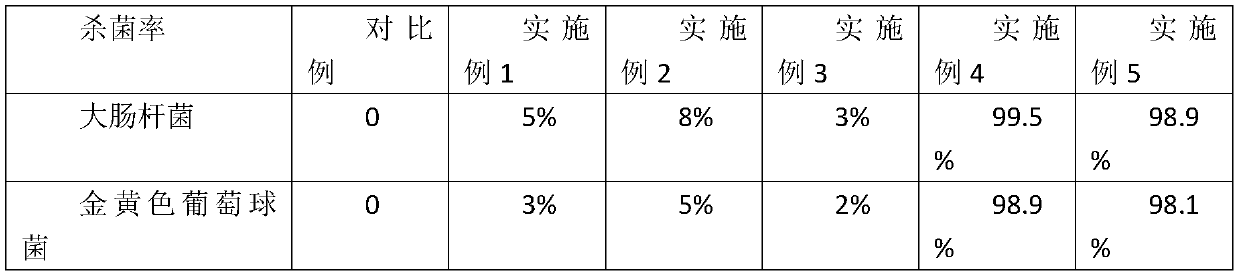

Examples

preparation example Construction

[0024] like figure 1 and figure 2 Shown, a kind of preparation method of near-infrared photoresponsive type sterilization-deadhesion wrinkled surface comprises the steps:

[0025] 1) Add the carbon nanomaterials covered with TEOS into the PDMS / xylene solution, ultrasonically disperse the carbon nanomaterials completely, then remove the solvent, add a curing agent, and solidify to form a film to obtain a soft base of the film-based wrinkling system:

[0026] 2) The solution obtained by dissolving the polymer material and photosensitizer in an organic solvent is spin-coated on the PDMS soft substrate rich in carbon nanomaterials, and the sample after spin coating is processed in a vacuum oven to remove the organic solvent, and the polymer material is obtained as a surface. Hard film, carbon nanomaterials / PDMS is a composite film structure with soft substrate.

[0027] 3) The composite film layer is irradiated with near-infrared light (such as 808nm) for a certain period of ti...

Embodiment 1

[0042] 2 mg of single-walled carbon nanotubes (CNTs) were pre-soaked in TEOS solution for 2 h, and then centrifuged at 3000 r / min to remove the supernatant. The CNTs obtained after centrifugation were added to a 16g PDMS / 20ml xylene solution, and ultrasonicated at 30°C for 12h. Then place it in a vacuum oven at 70°C for 24 hours to remove xylene, then add 1.6g of curing agent, pour the mixed solution into a mold prepared in advance, and then place it in a vacuum oven at 70°C for 24 hours to obtain a film base Soft base for creping systems.

[0043] Cut the prepared PDMS / CNT soft substrate into equal large pieces, ultrasonically clean them with water and ethanol respectively, and dry them for later use. Add 100 mg of polymethyl methacrylate (PMMA) into 10 ml of xylene, and sonicate for 0.5 h. Spin-coat 100 μl of PMMA solution on the PDMS / CNT soft substrate at a speed of 1500r / min, and treat the spin-coated sample in a vacuum oven at room temperature for 12 hours to remove the...

Embodiment 2

[0047] 1.6 mg of single-walled carbon nanotubes (CNTs) were pre-soaked in TEOS solution and sonicated for 1 h, and then centrifuged at 3000 r / min to remove the supernatant. The CNTs obtained after centrifugation were added to a 16g PDMS / 20ml xylene solution, and ultrasonicated at 30°C for 8h. Then place it in a vacuum oven at 60°C for 36 hours to remove xylene, then add 1.6g of curing agent, pour the mixed solution into a mold prepared in advance, and then place it in a vacuum oven at 60°C for 36 hours to obtain a film base Soft base for creping systems.

[0048] Cut the prepared PDMS / CNT soft substrate into equal large pieces, ultrasonically clean them with water and ethanol respectively, and dry them for later use. Add 200mg of polyvinyl alcohol (PVA) into 10ml of xylene, and sonicate for 0.5h. Spin-coat 100 μl of PVA solution on the PDMS / CNT soft substrate at a speed of 1500r / min, and treat the spin-coated sample in a vacuum oven at room temperature for 12 hours to remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com