Continuous carbonation decomposition for high concentration sodium aluminate solution

A technology of carbonation decomposition and sodium aluminate, which is applied in the direction of alkali metal aluminate/alumina/aluminum hydroxide preparation, etc., which can solve the problems of increasing aluminum hydroxide circulation, high equipment and power consumption, and large material circulation flow, etc. problems, to achieve the effect of reducing production costs, reducing equipment and power consumption, and reducing circulation flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

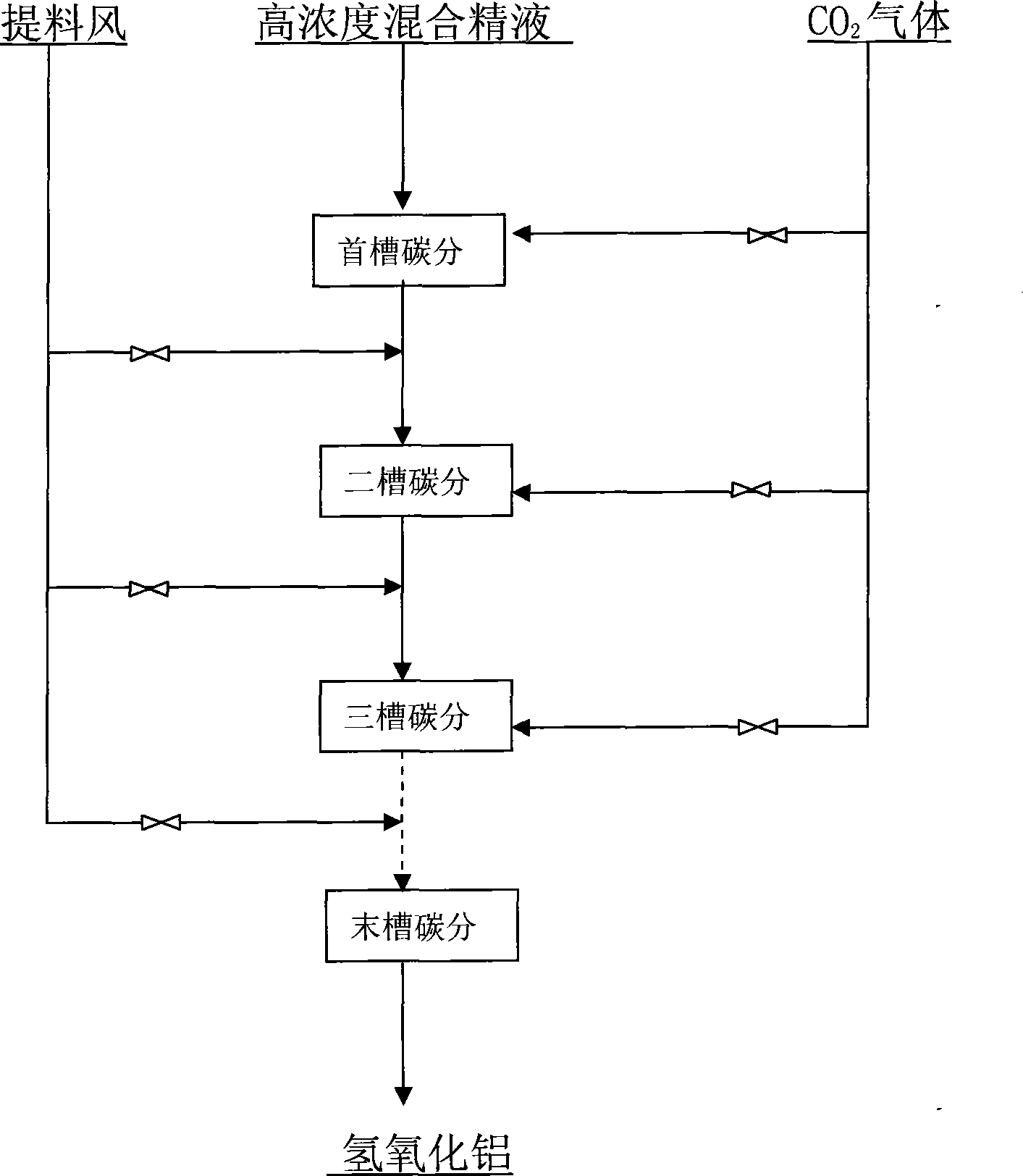

Embodiment 1

[0017] The obtained alumina concentration is 165g / l, α k The 1.42 sintering method-Bayer method mixed semen, the semen is pumped to four carbon tanks for three-stage continuous carbonation decomposition, and the first three carbon tanks are fed with CO 2 The gas is continuously carbonated and decomposed, and the last one is the discharge tank. The process conditions are controlled as follows: the first tank is fed with CO 2 There are three gas pipes of φ159, the residence time is controlled to be about 3 hours, and the decomposition rate is controlled at 25±2%; the second tank is fed with CO 2 The gas pipeline is φ159 with 5 pieces, the residence time is controlled to be about 4 hours, the decomposition rate is controlled at 70±2%, and the third tank is fed into CO 2 The gas pipeline is φ159 for 2 pieces, the residence time is controlled to be about 3 hours, and the decomposition rate is controlled at 87±2%; the fourth tank does not enter CO 2 Gas, stay and discharge, contro...

Embodiment 2

[0019] The prepared alumina concentration is 178g / l, α k The 1.43 sintering method-Bayer method mixed semen, the semen is pumped to four carbon tanks for three-stage continuous carbonation decomposition, and the first three carbon tanks are fed with CO 2 The gas is continuously carbonated and decomposed, and the last one is the discharge tank. The process conditions are controlled as follows: the first tank is fed with CO 2 There are three gas pipes of φ159, the control residence time is about 3.5 hours, and the decomposition rate is controlled at 25±2%; the second tank is fed into CO 2 The gas pipeline is 5 pieces of φ159, the residence time is controlled to be about 3.5 hours, the decomposition rate is controlled at 70±2%, and the third tank is fed into CO 2 The gas pipeline is φ159 for 2 pieces, the residence time is controlled to be about 3.5 hours, and the decomposition rate is controlled at 87±2%; the fourth tank does not enter CO 2 Gas, stay and discharge, control the...

Embodiment 3

[0021] The obtained alumina concentration is 182g / l, α k The 1.44 sintering method-Bayer method mixed semen, the semen is pumped to five carbon tanks for four-stage continuous carbonation decomposition, and the first four carbon tanks are fed with CO 2 The gas is continuously carbonated and decomposed, and the last one is the discharge tank. The process conditions are controlled as follows: the first tank is fed with CO 2 There are three gas pipes of φ159, the residence time is controlled to be about 3 hours, and the decomposition rate is controlled at 25±2%; the second tank is fed with CO 2 The gas pipeline is φ159 with 5 pieces, the residence time is controlled to be about 3 hours, the decomposition rate is controlled at 60±2%, and the third tank is fed into CO 2 The gas pipeline is φ159 with 5 pieces, the residence time is controlled to be about 3 hours, the decomposition rate is controlled at 70±2%, and the fourth tank is fed into CO 2 The gas pipeline is φ159 with 2 pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com