Apparatus for manufacturing optical fiber preform part

A technology for optical fiber preforms and pipes, which is applied in the field of optical fiber manufacturing to achieve the effects of slowing airflow turbulence, reducing uneven temperature distribution, and avoiding uneven density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following description will be made according to the embodiments of the present invention. However, the following embodiments do not limit the inventions related to the claims.

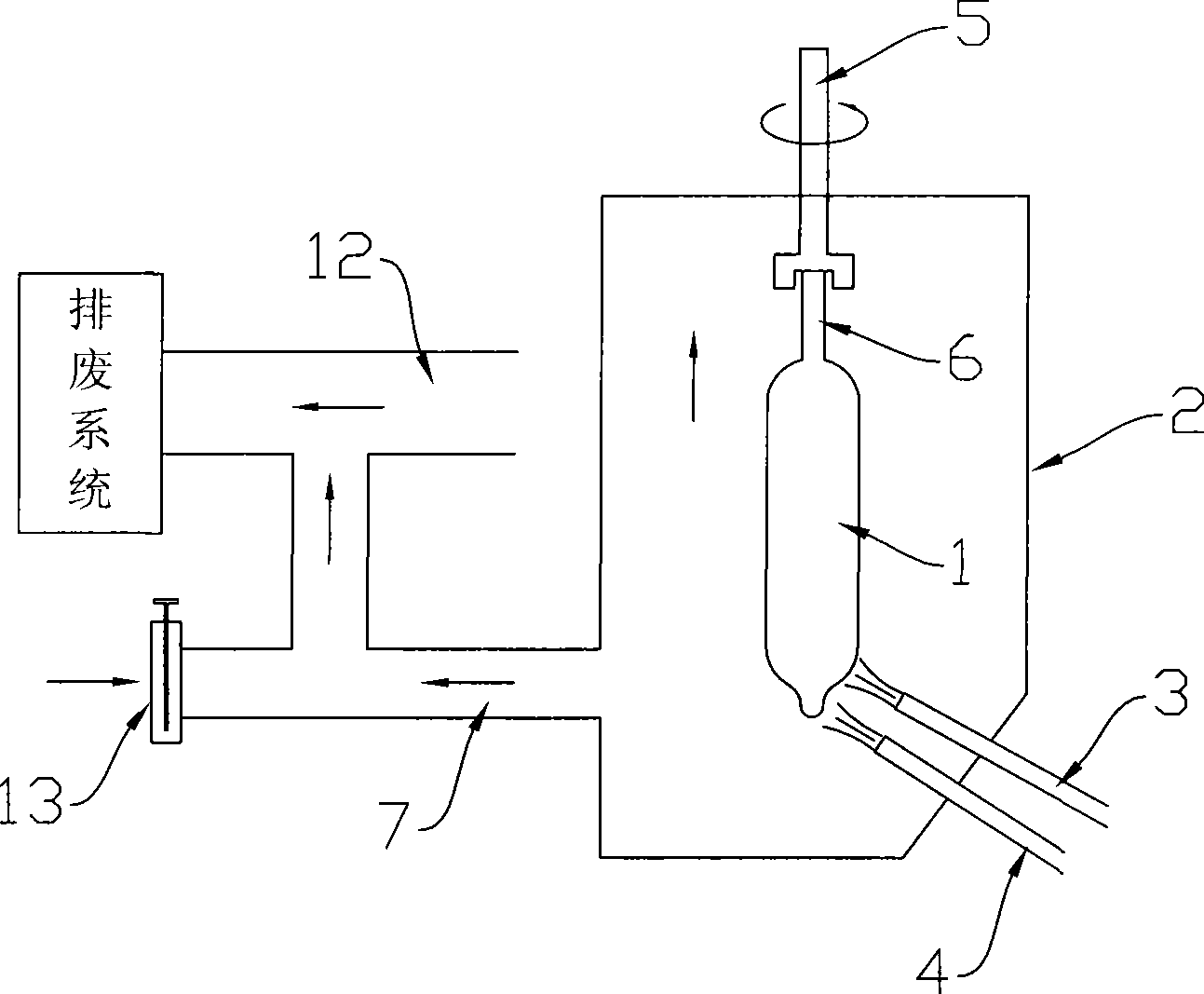

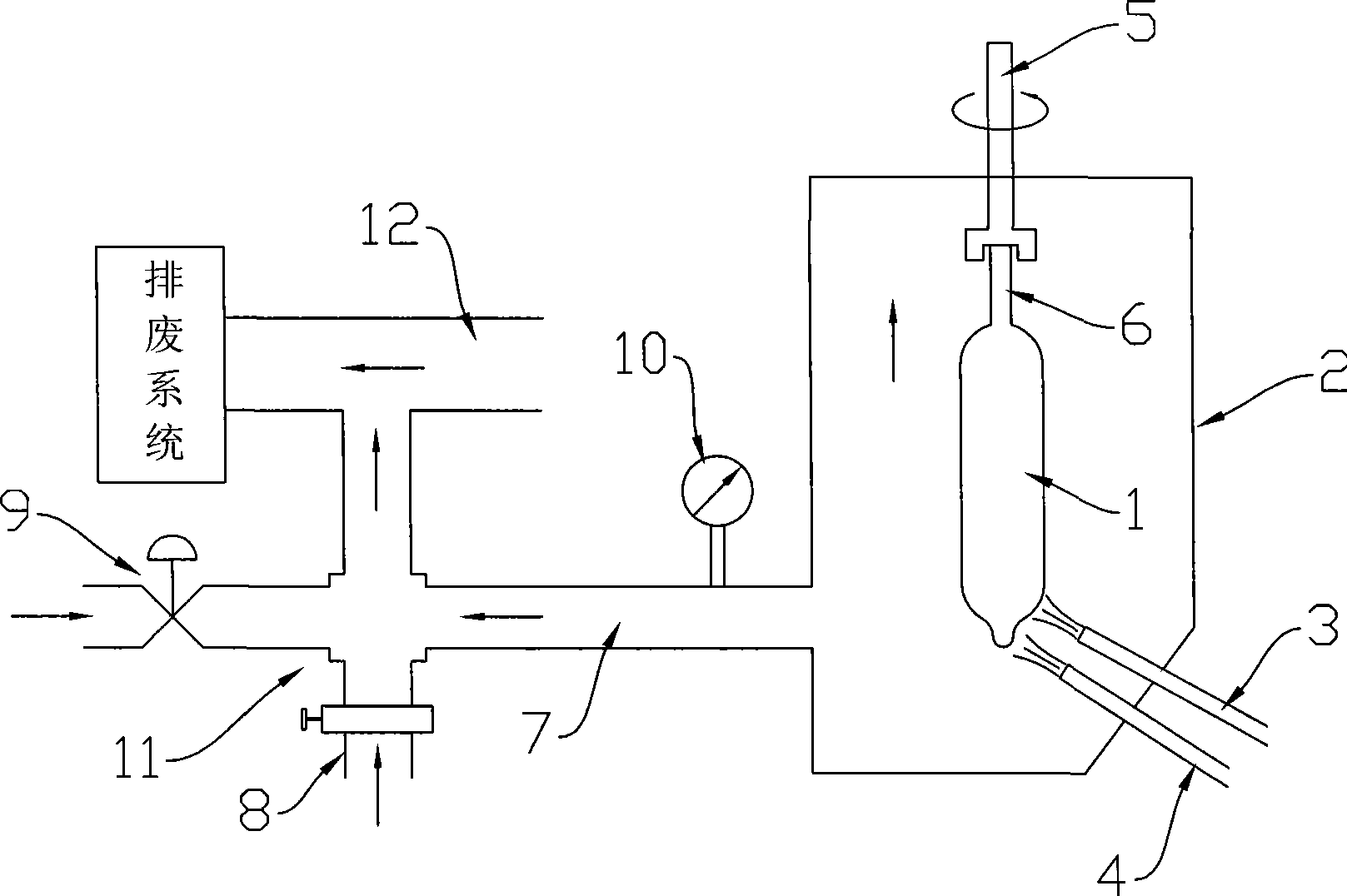

[0016] Such as figure 2 The shown device for manufacturing optical fiber preforms has a reaction vessel 2 for vapor phase axial deposition, and the reaction vessel 2 has a waste discharge pipe 7: the waste discharge pipe 7 includes an automatic adjustment for making up air. The pressure valve 9, the pressure gauge 10, and the automatic pressure regulating device of the manual pressure regulating valve 8 for supplementing air are connected to the main waste discharge pipeline 12, and the main waste discharge pipeline 12 is connected to the waste discharge system.

[0017] Further, a four-way pipeline interface 11 is connected to the waste discharge pipeline 7, and the waste discharge pipeline 7 is connected to an interface of the four-way pipeline interface 11. The automatic pressure regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com