Material for passing by ultraviolet or near-ultraviolet and use thereof

A technology of light-transmitting materials and light, which is applied in the direction of optical elements, fluorescent screen lamps, and lighting device components used to change the spectral characteristics of emitted light. Degradation and other problems, to achieve the effect of stable light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

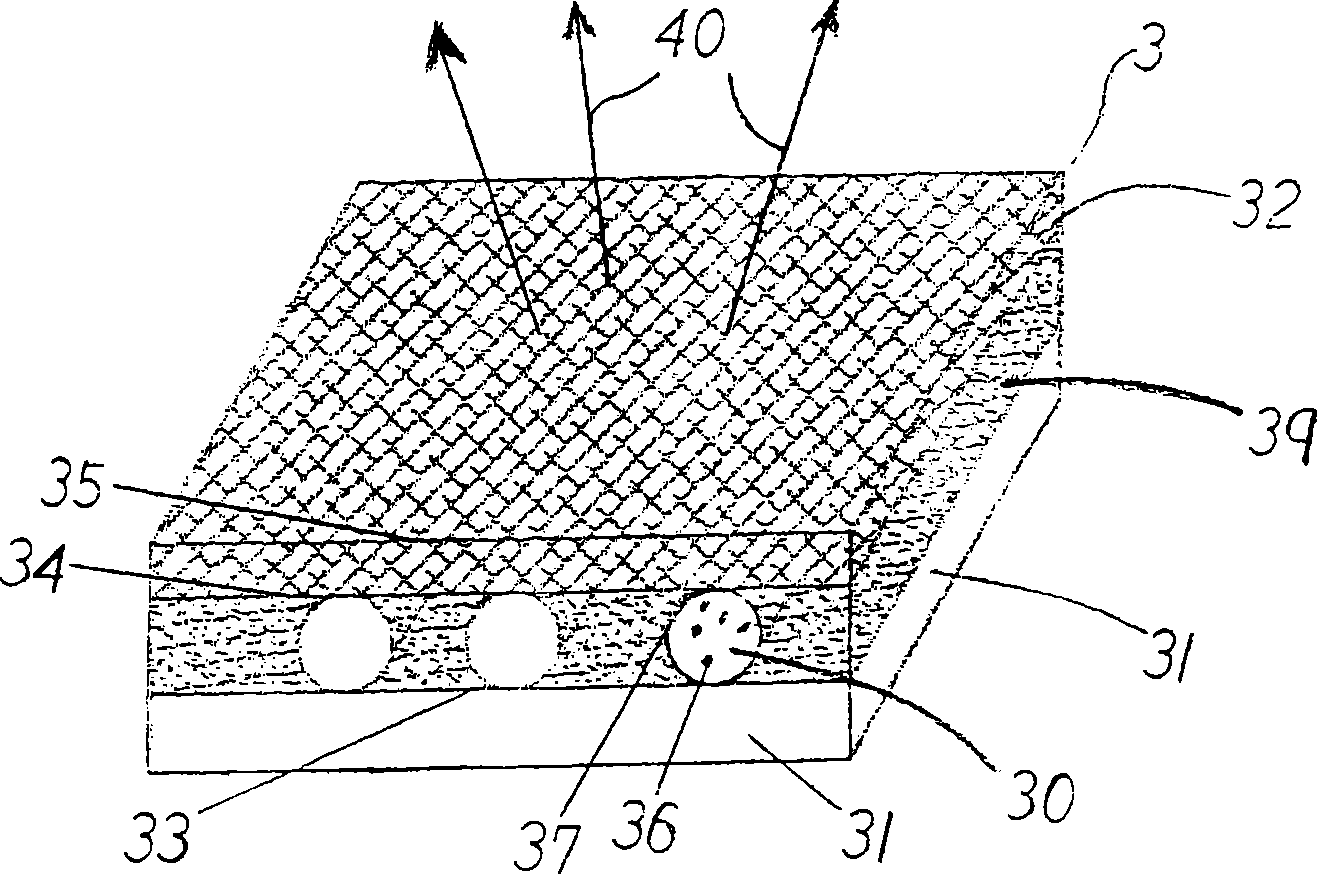

[0036] The features and advantages of the present invention can be seen from the following description and accompanying drawings. Other objectives of the present invention can also be further seen from the following description and accompanying drawings.

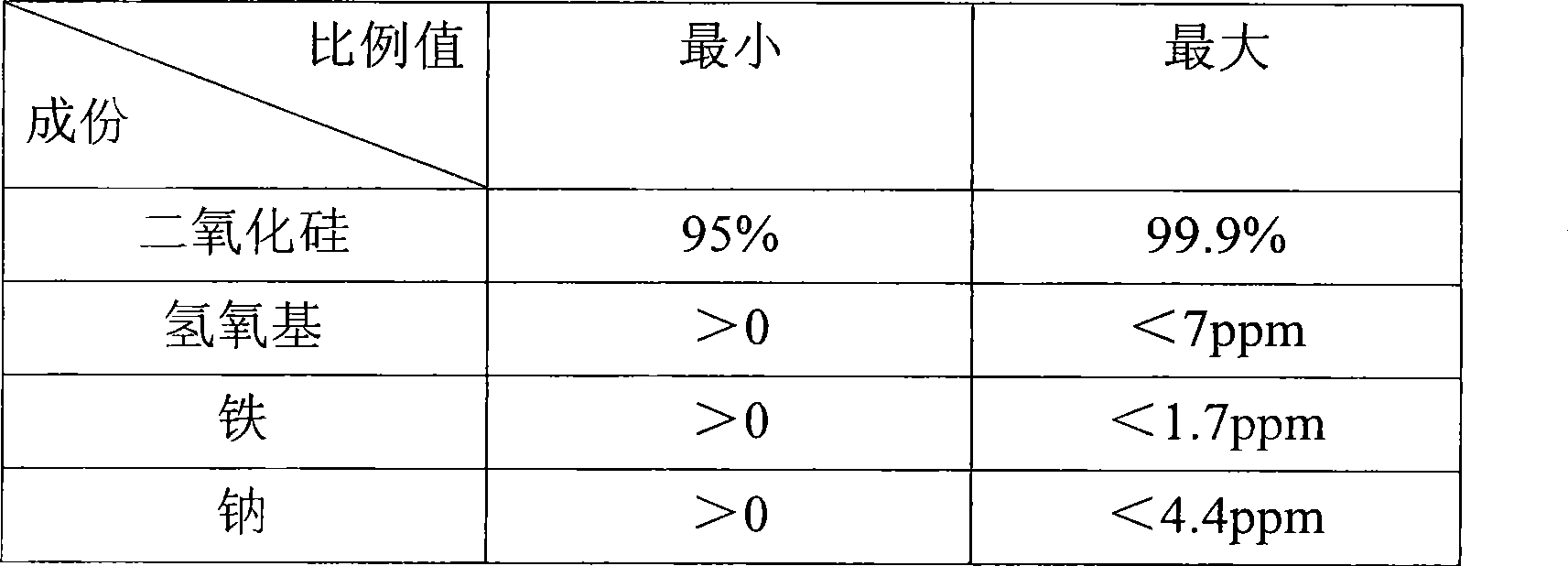

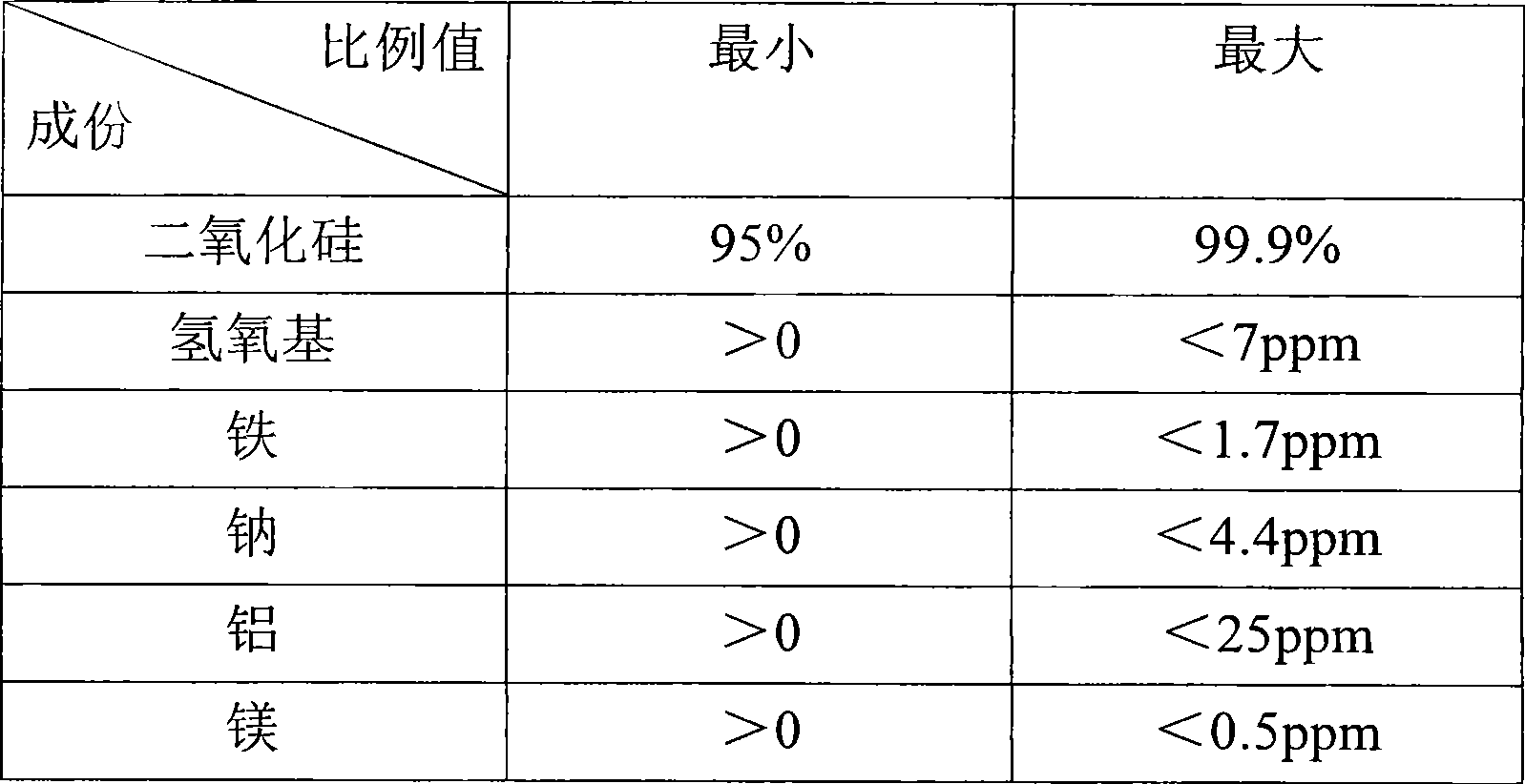

[0037] The first article provided by the present invention is a light-transmitting material, which can provide most or at least a part of a light with a wavelength of at least 200 nanometers, with a higher and more stable light transmittance Through, the light-transmitting material of the present invention contains components such as silicon dioxide, hydroxide, metal, etc., and the weight ratio value (or concentration) of the silicon dioxide is at least 95% and at most 99.9%. The composition ratio value (or concentration) is greater than 0 and less than 7ppm, the metal composition contains iron and sodium, the composition ratio value (or concentration) of the iron is greater than 0 and less than 1.7ppm, the composition ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com