Dual-spindle surface shearing stress sensor

A technology of shear stress and sensors, which is applied in semiconductor/solid-state device components, fluid pressure measurement using capacitance changes, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem that the surface shear stress cannot be realized at the same time Size measurement and determination of fluid direction, etc., to achieve the effect of miniaturization and improvement of resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

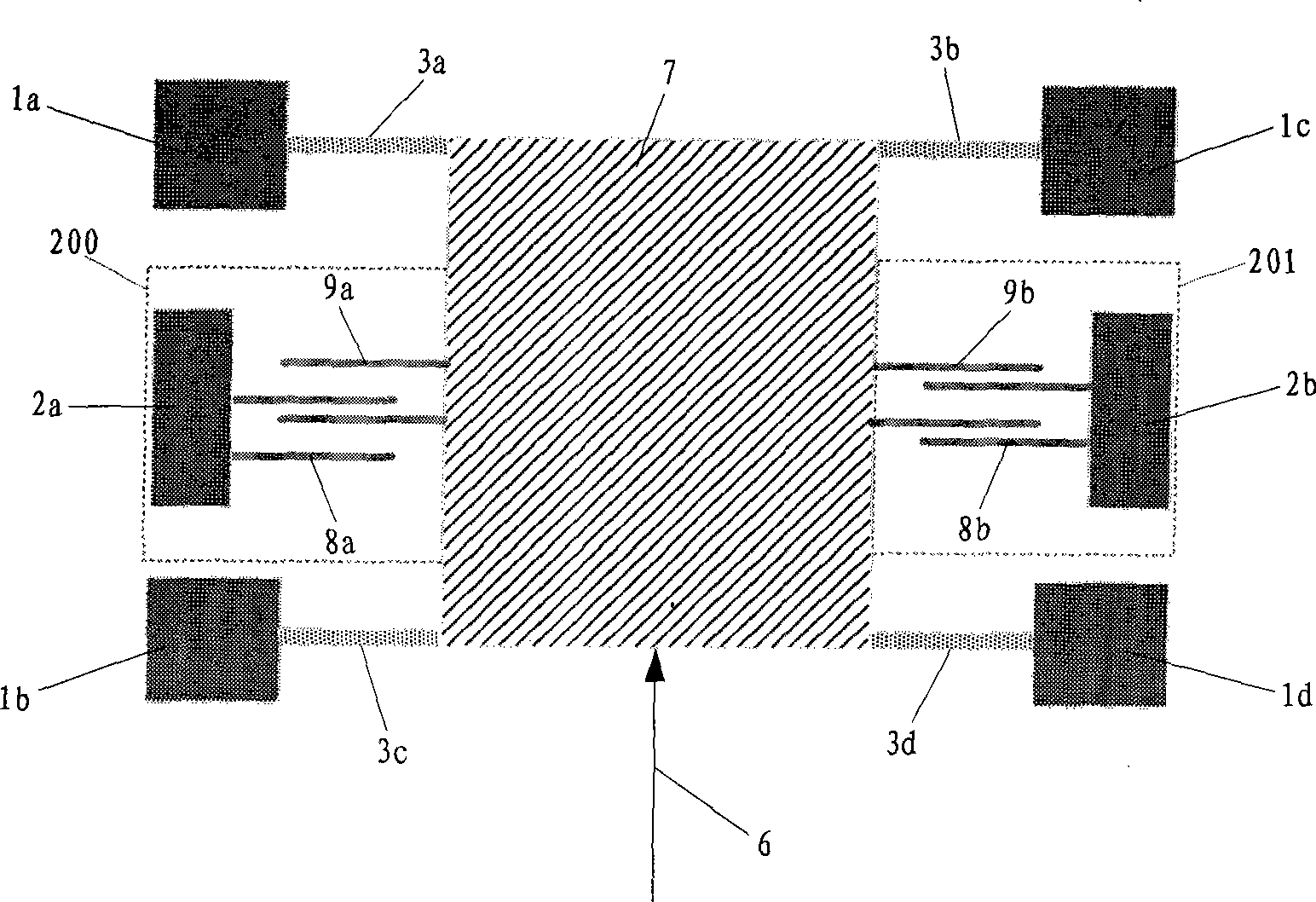

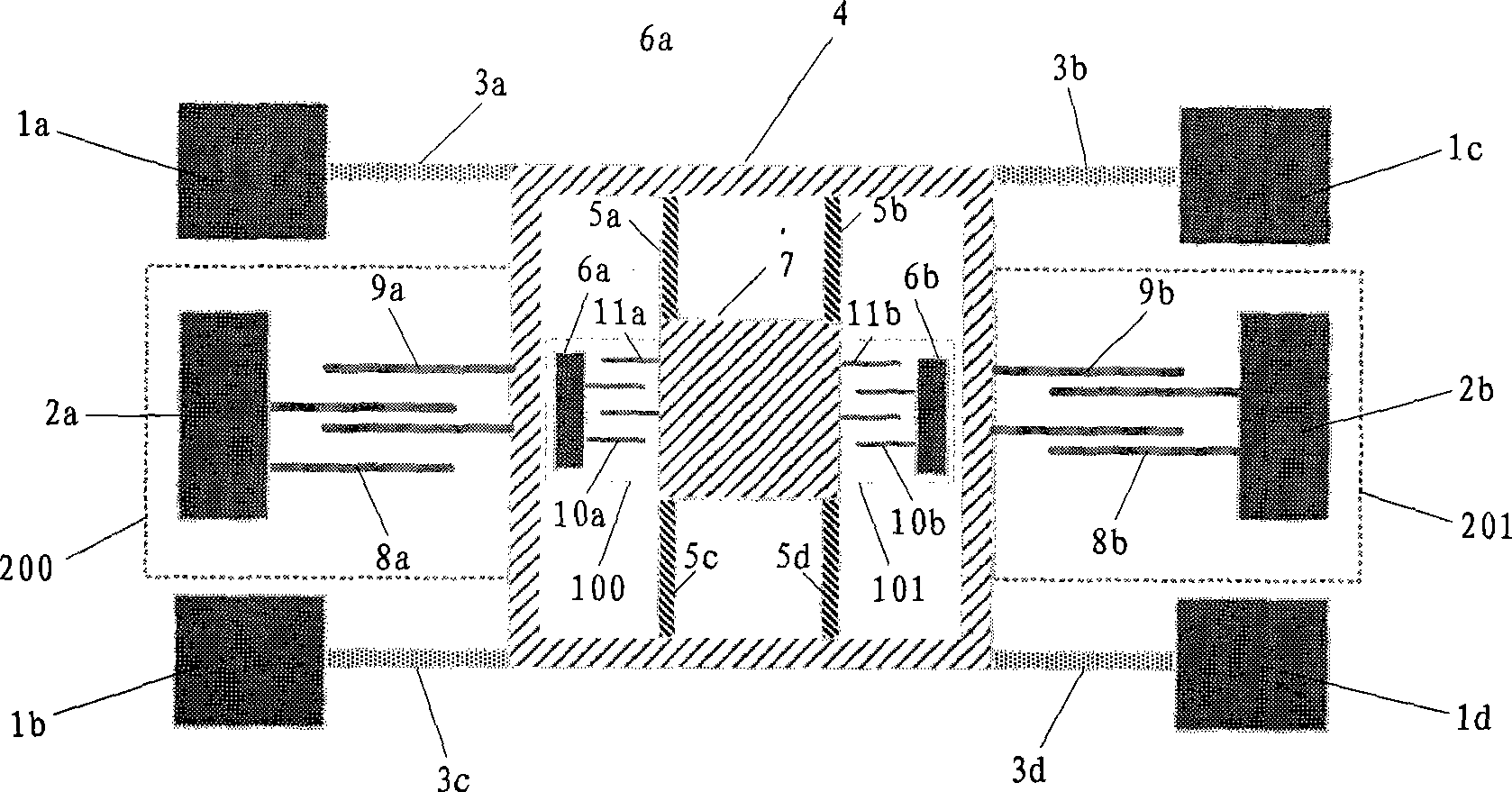

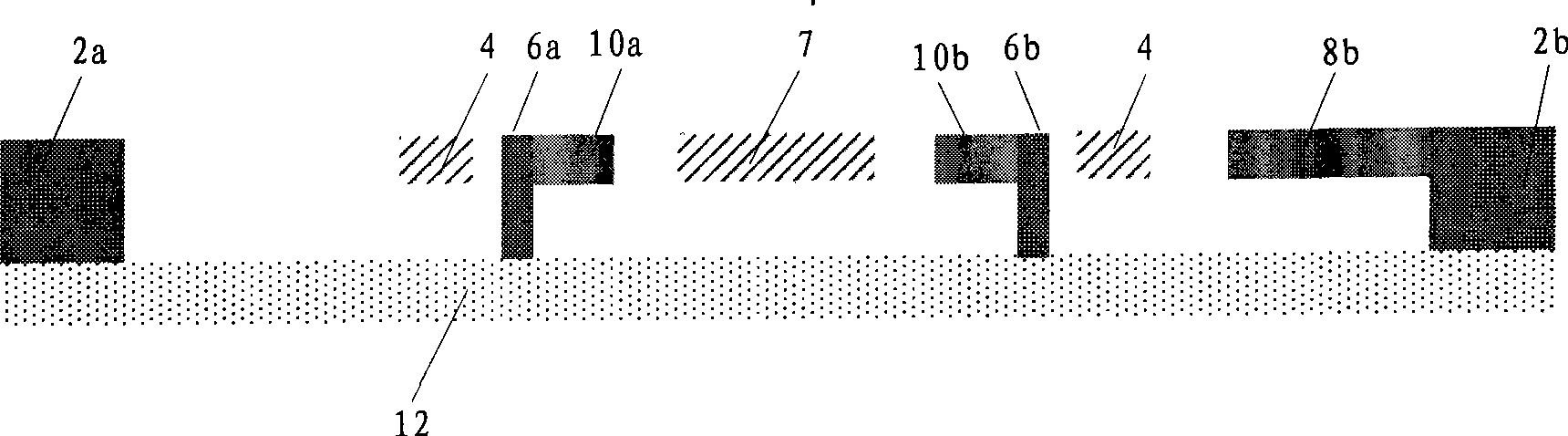

[0015] combine figure 2 , the biaxial surface shear stress sensor of the present invention includes fixed bases 1a, 1b, 1c, 1d, external fixed comb electrodes 2a, 2b, external support beams 3a, 3b, 3c, 3d, floating unit 7, external fixed combs Teeth 8a, 8b and external sensitive combs 9a, 9b, the external fixed combs 8a, 8b and external sensitive combs 9a, 9b form sensitive capacitors 200, 201 respectively, and the two sensitive capacitors 200, 201 form a Differential capacitor structure, the external fixed comb teeth 8a, 8b are respectively connected with the external fixed comb teeth electrodes 2a, 2b, and consist of upper and lower layers, the upper layer is the surface shear stress sensor mechanical structure made on the single crystal silicon wafer, the lower layer For making the signal leads on the glass substrate, the fixed base 1a, 1b, 1c, 1d, the external fixed comb electrodes 2a, 2b, the external fixed comb teeth 8a, 8b, the external sensitive comb teeth 9a, 9b, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com