Delivery conduit of plastic foam environment friendly recycling prilling unit

A foamed plastic and conveying pipeline technology, which is applied in the field of conveying pipelines, can solve the problems of poor labor environment, low production efficiency and improper relationship handling of operators, and achieves the effect of solving low recycling efficiency, improving utilization efficiency and reducing recycling cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

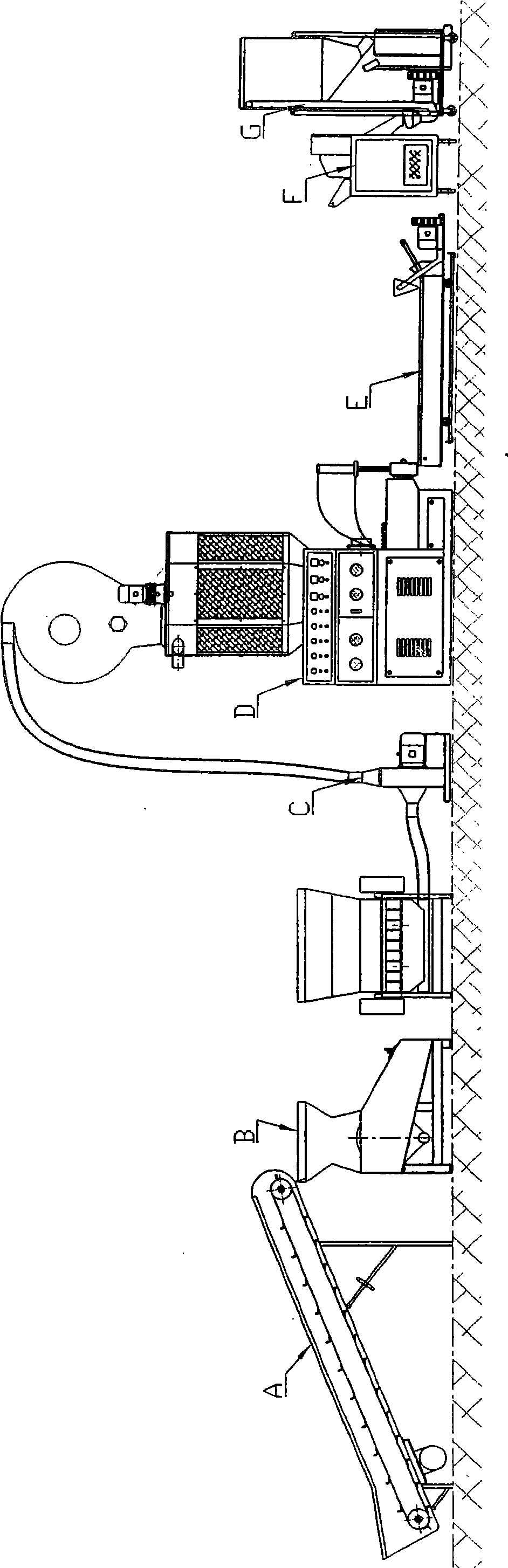

[0031] Such as figure 1 The foam plastic environmental protection recycling granulation unit shown is composed of a feeding conveyor A, a foam plastic special pulverizer B, a feeding fan and a conveying pipeline C, a main machine D, a water tank E, a granulator F, a storage tank and a weighing machine. Heavy equipment G composition.

[0032] Conveyor for feeding

[0033] The entire conveying mechanism is composed of a traction wheel, a driven wheel, a conveyor belt, a corner rubber block and a motor with a reducer. And the main frame and conveyor belt of the conveyor are designed to be widened and heightened, especially for the transportation of foam plastics. According to the actual use requirements, a metal detector is also configured.

[0034] grinder

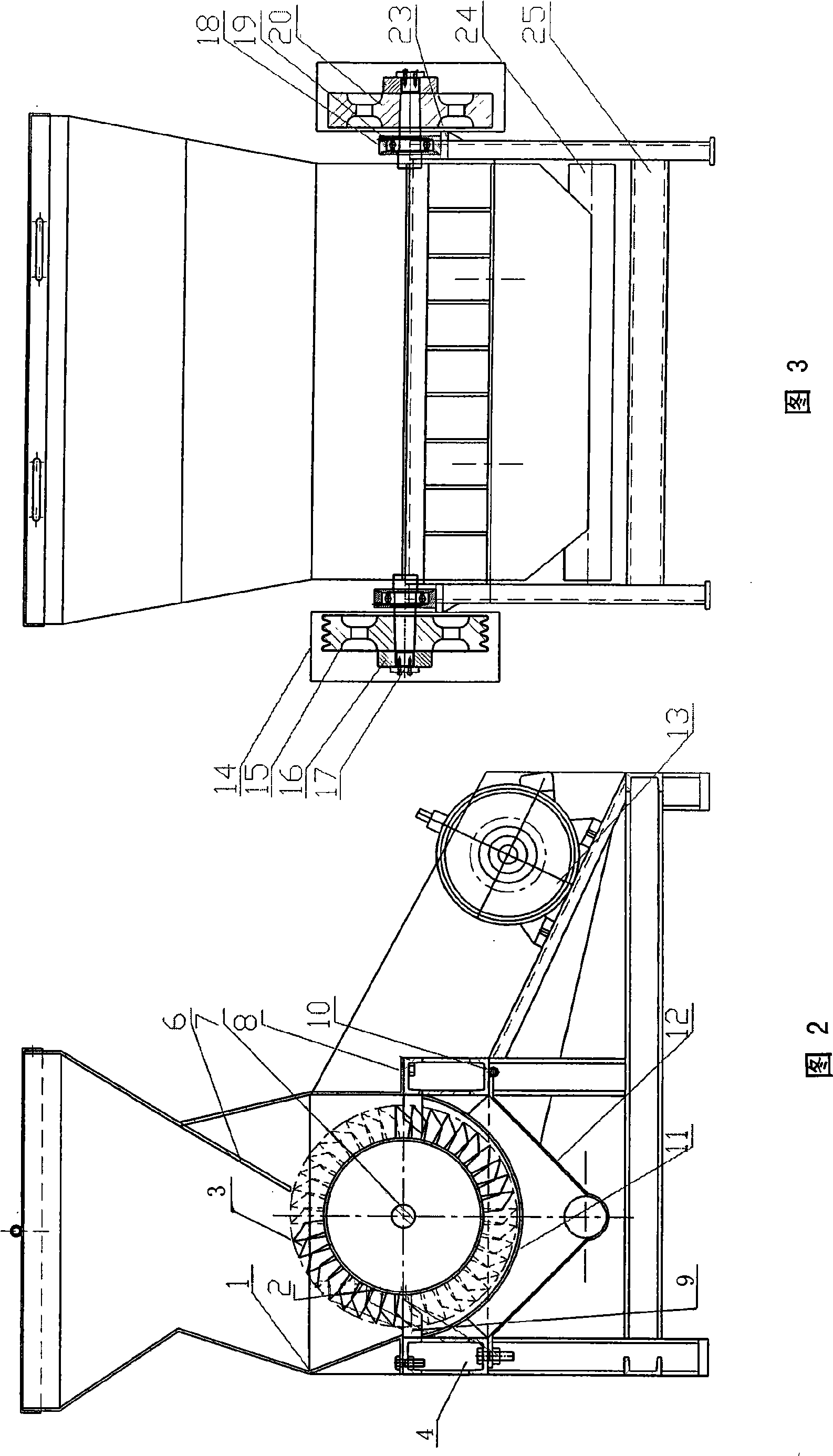

[0035] As shown in Fig. 2 and Fig. 3, the feed body is composed of an upper body 1 and an intermediate body 2 connected under the upper body. The upper body and the intermediate body are connected by bolts 8. The functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com