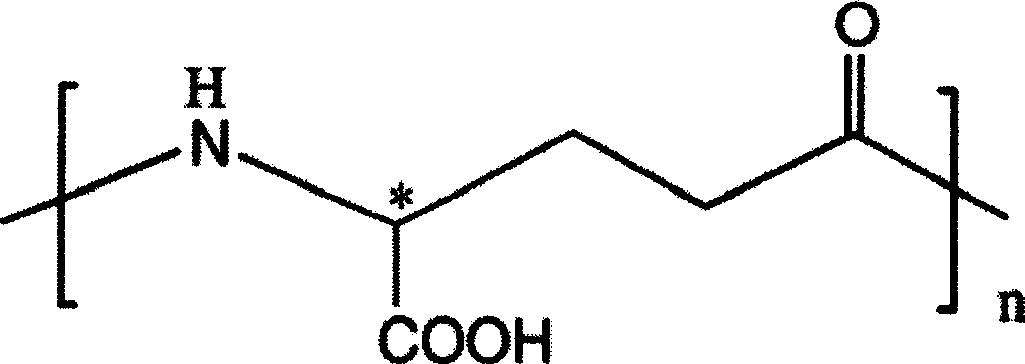

Bacillus subtilis and method for preparing gamma-polyglutamic acid by using the same

A technology of Bacillus subtilis and polyglutamic acid, applied in the field of Bacillus subtilis and the preparation of γ-polyglutamic acid by the bacteria, can solve the problems of long cycle, low production efficiency, high cost, etc., and achieve increased output and reduced viscosity , the effect of low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

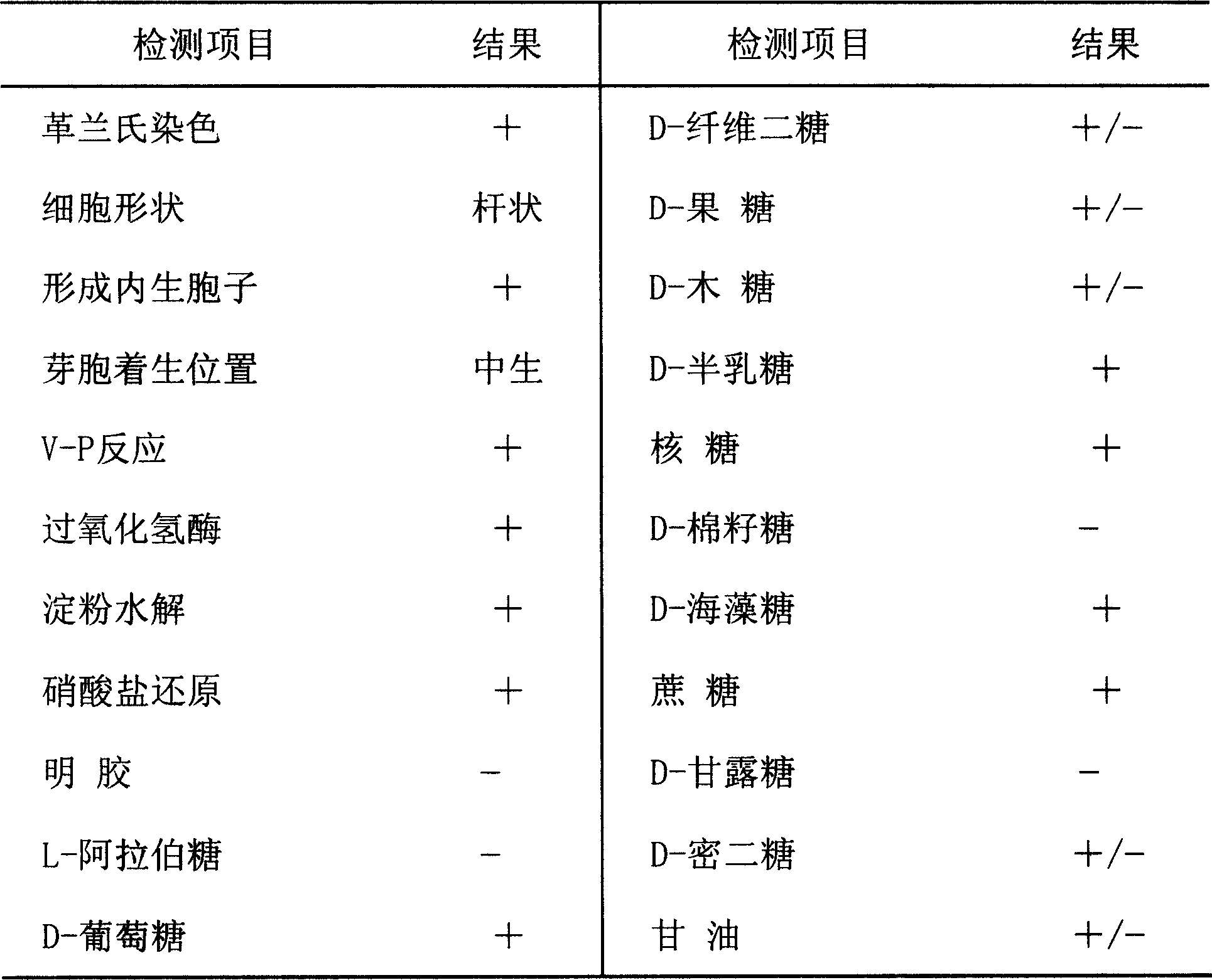

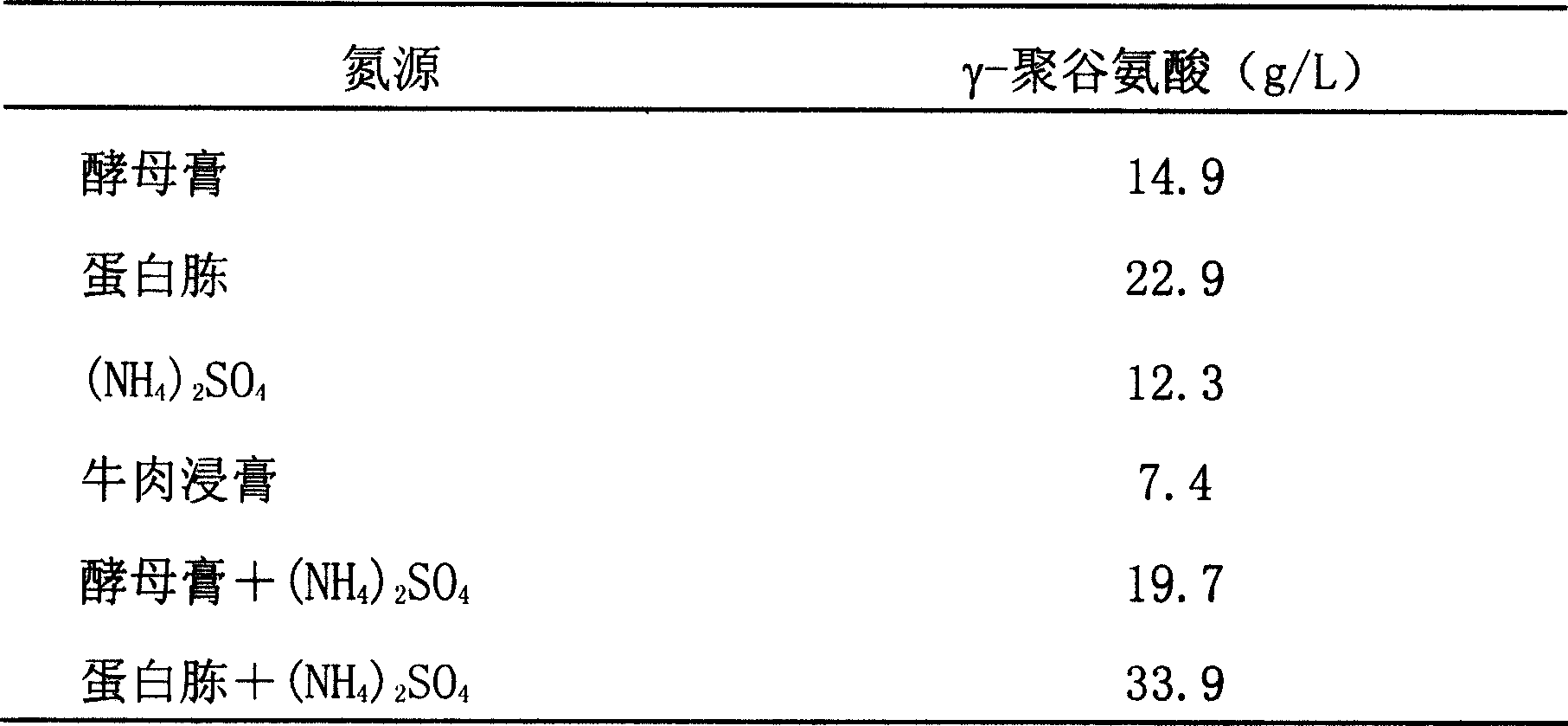

Method used

Image

Examples

Embodiment 1

[0041] Bacillus subtilis (Bacillus subtilis) XN01 was cultured on a solid slope at a constant temperature of 37°C for 24 hours, and then stored at 2-4°C. The composition of the slant medium described therein is: 1% peptone, 0.5% yeast extract, 1% NaCl, 2.0% agar, and the pH value is 6.0.

[0042] Take about 1cm from the inclined plane 2 Bacillus subtilis (Bacillus subtilis) XN01 was inoculated into the seed medium, and cultured in a shaker flask at 37° C. for 20 hours at a rotation speed of 210 rpm. The composition of the seed culture medium is as follows: 1% glucose, 1% peptone, 0.5% yeast extract, 1% NaCl, pH 7.1-7.2, and the filling volume is 50ml / 250ml shake flask.

[0043] The seed culture medium was inserted into the fermentation medium according to the inoculum amount of 5%, and cultured in a shaker flask at 37° C. for 24 hours at a rotation speed of 210 rpm. The fermentation medium described therein consists of: 3% sucrose, 5% L-glutamic acid, 1.0% yeast extract, MgS...

Embodiment 2

[0047] Same as Example 1, the carbon source was changed to maltose with the same mass concentration, and the analysis results showed that the content of γ-polyglutamic acid in the fermentation broth was 30.1 g / L.

Embodiment 3

[0049] Bacillus subtilis (Bacillus subtilis) XN01 was activated in the same seed medium as Example 1 for 15 hours, then pressed into the shake flask fermentation medium according to 5% inoculum size, and cultured in the shake flask at 37° C. for 24 hours at a rotation speed of 210 rpm. The fermentation medium described therein consists of: glucose 3%, L-glutamic acid 5%, peptone 0.8%, NaCl 1%, MgSO 4 ·7H 2 O 0.05%, MnSO 4 ·H 2 O 0.01%, K 2 HPO 4 0.1%, the pH value is 7.4~7.5, the filling volume is 50ml / 250ml shake flask.

[0050] After the fermentation, the content of gamma-polyglutamic acid in the fermentation broth was detected according to the paper chromatography method of Example 1, and the result showed that the content was 48.0 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com